Sensor assembly for automatic dryer

A sensor component and sensor technology, which is applied in the field of dryers, can solve the problems of drying time period, heater and blower motor working beyond the required time, drying performance cannot be guaranteed, energy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to designate the same or like parts.

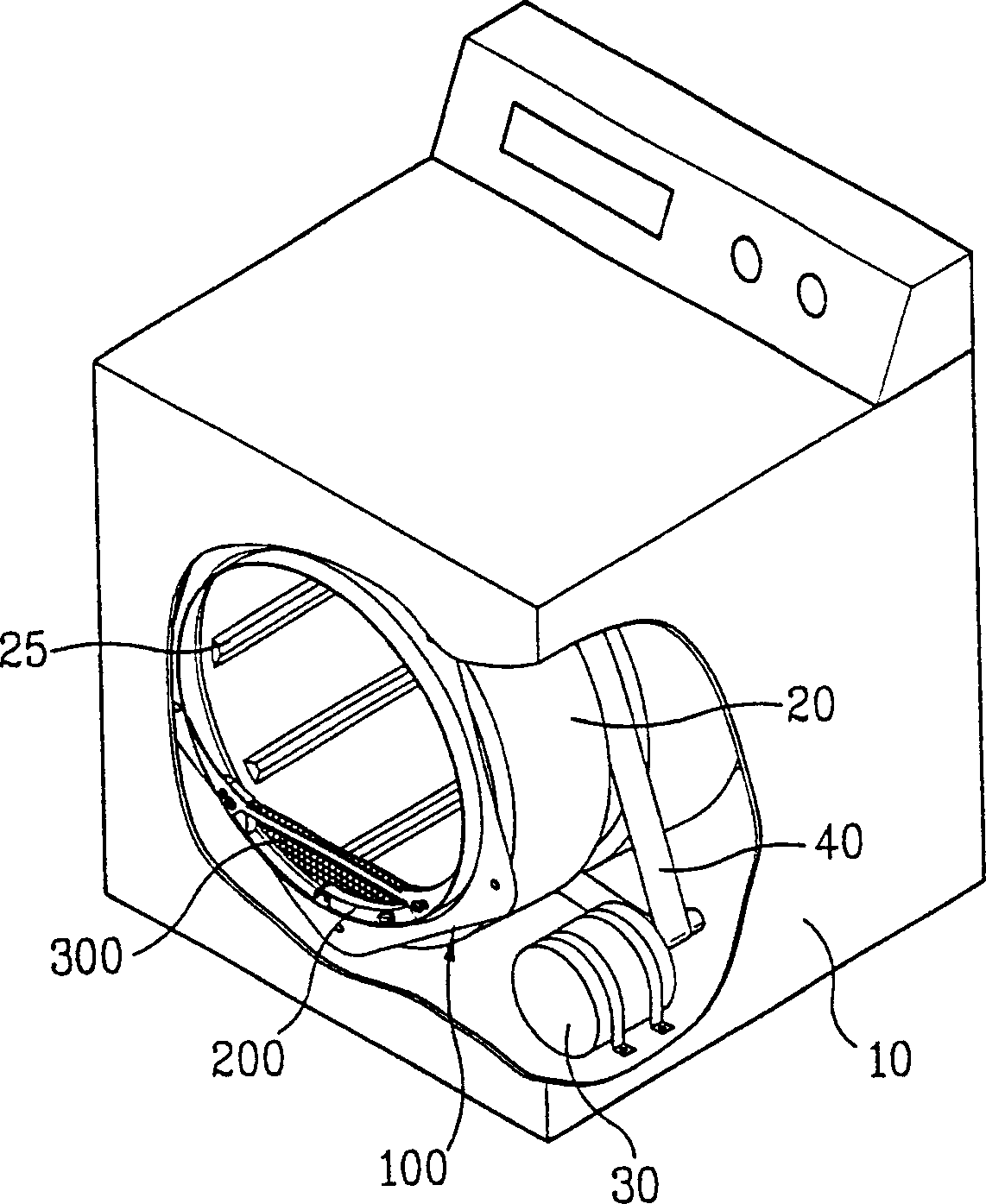

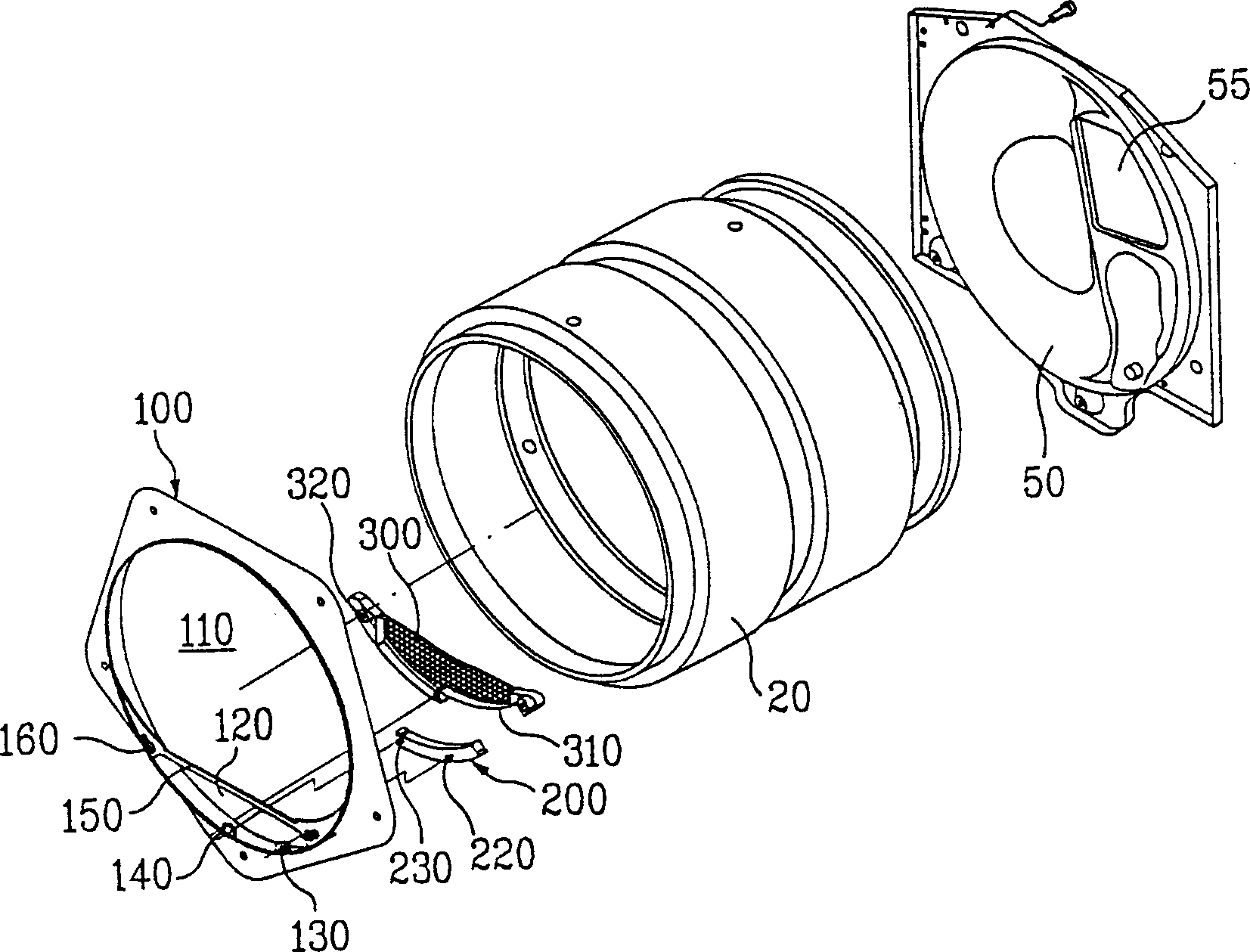

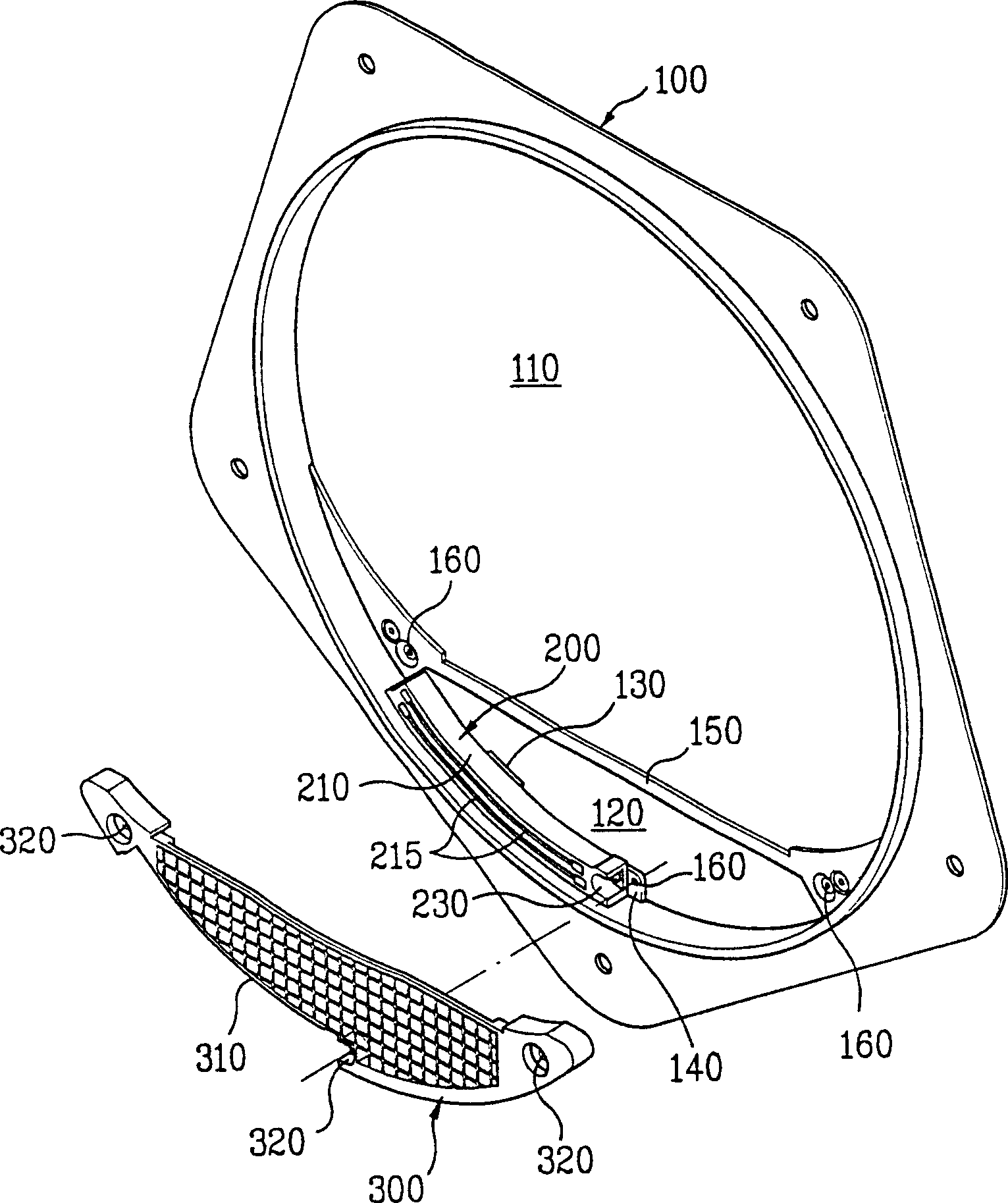

[0040] figure 1 is a partially cutaway perspective view showing the interior of a dryer according to a preferred embodiment of the present invention, figure 2 It is an exploded perspective view showing the combination of some parts of the dryer according to the preferred embodiment of the present invention.

[0041]refer to figure 1 with figure 2 , the drum 20 is rotatably mounted on figure 1 Shown in the cabinet 10 of the dryer. To this end, a belt 40 connects the motor 30 with the drum 20 installed inside the cabinet 10 . According to this system, since the belt 40 transmits power from the motor 30 to the drum 20 , the drum 20 can rotate inside the cabinet 10 .

[0042] The drum 20 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com