Manufacturing method of optical low pass filter

A technology of low-pass filters and manufacturing methods, applied in optics, optical components, nonlinear optics, etc., can solve problems such as time-consuming, reduced production efficiency, and poor production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

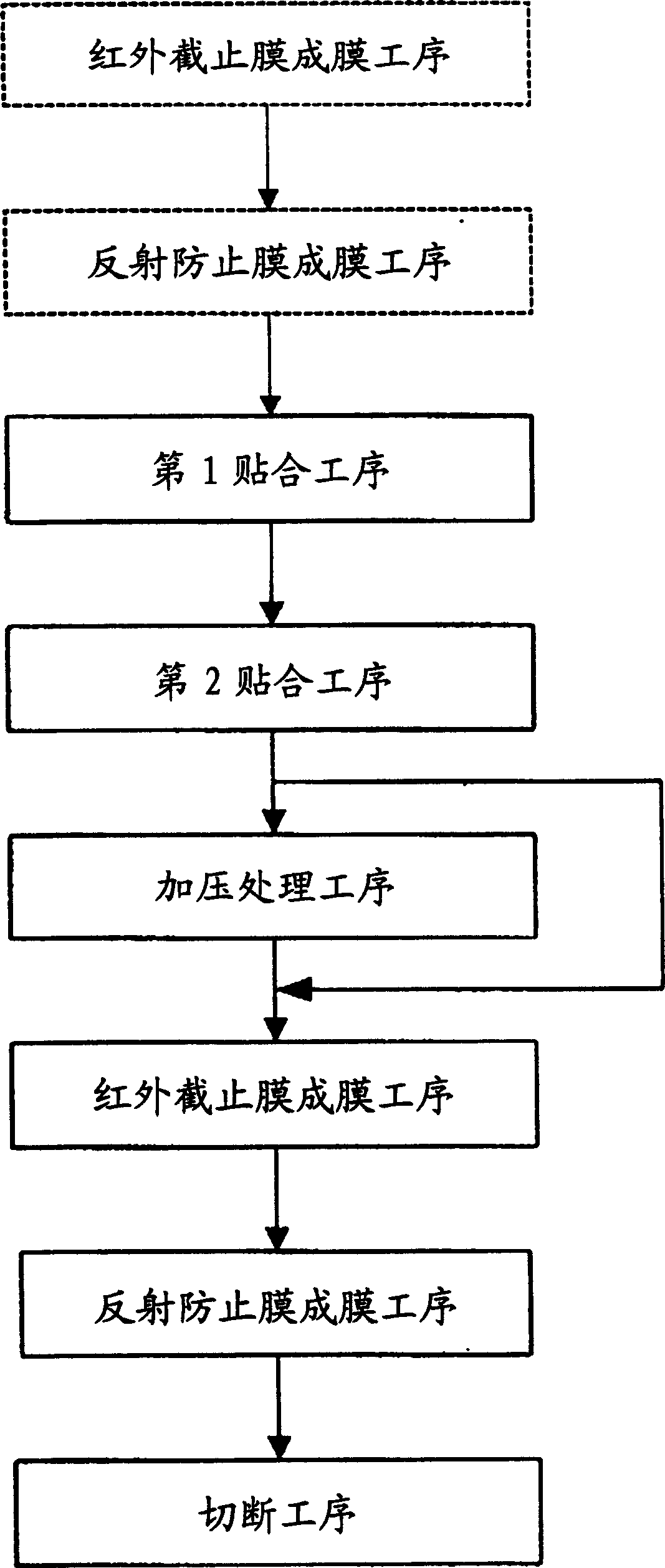

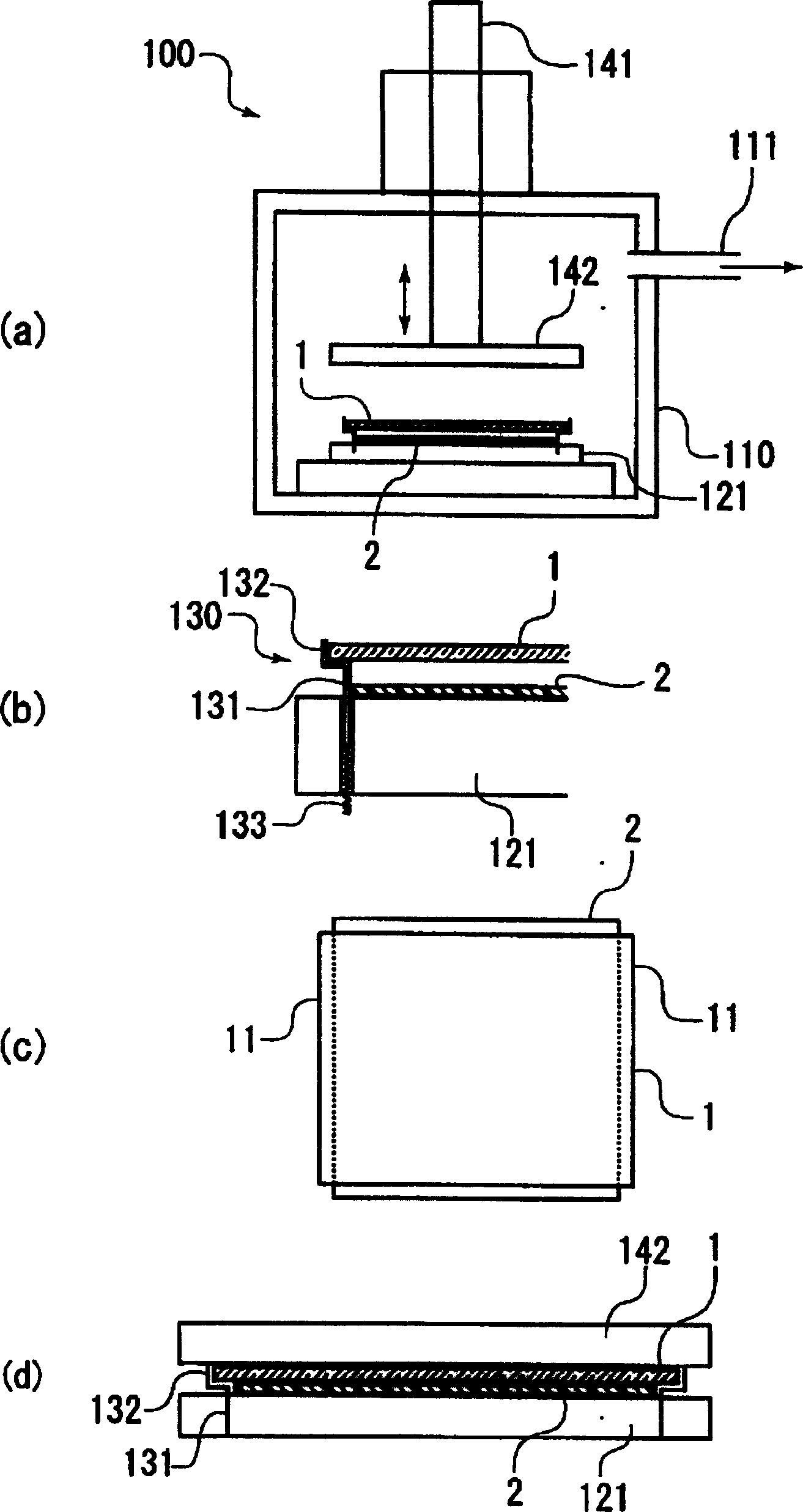

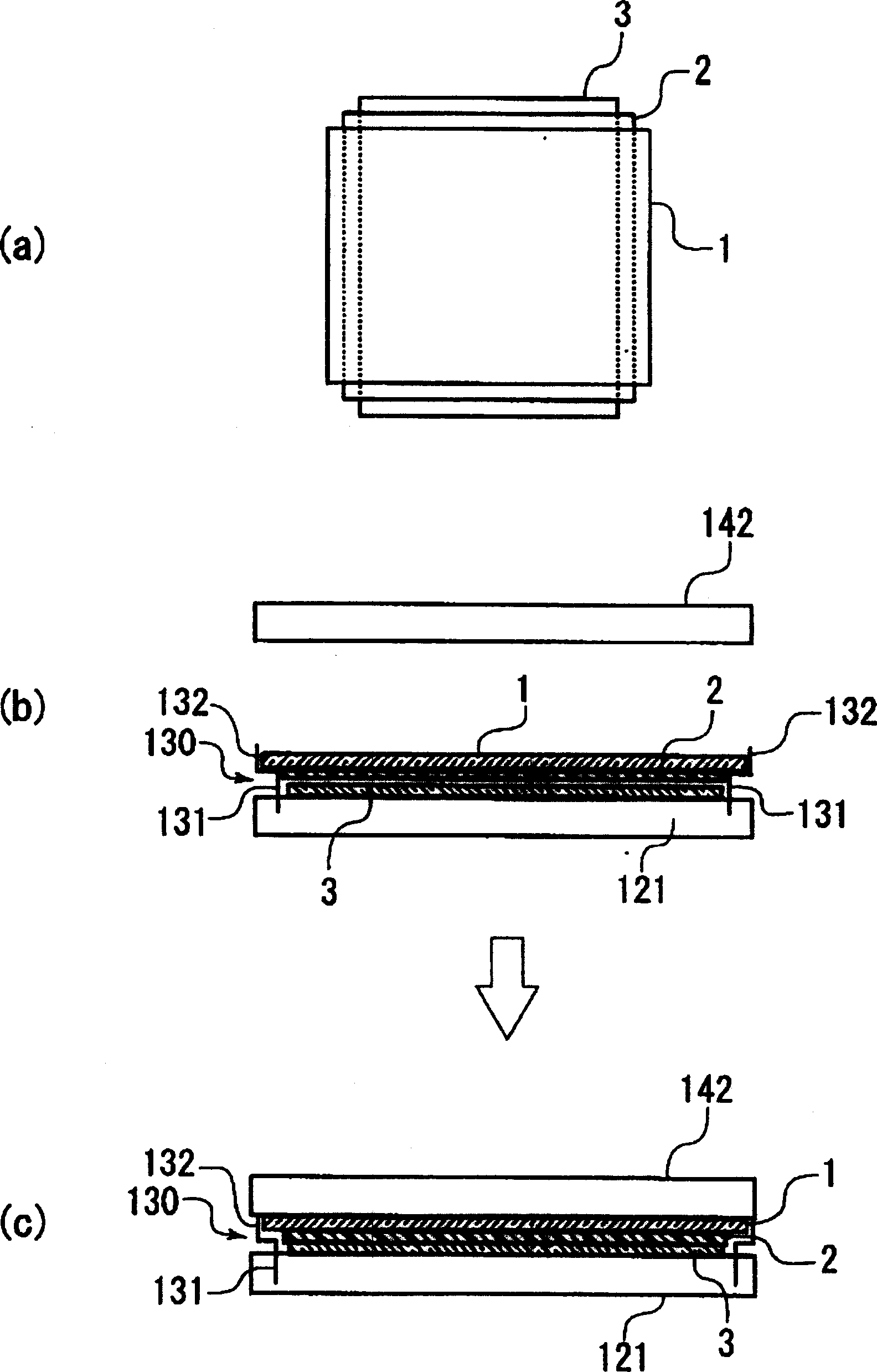

[0039] Hereinafter, embodiments of the method for manufacturing an optical low-pass filter of the present invention will be described, but the present invention is not limited to the following embodiments.

[0040] As an optical low-pass filter to be used in the method of manufacturing the optical low-pass filter of the present invention, a structure in which a 1 / 4 wavelength plate made of a polymer film is sandwiched between two birefringent plates can be cited. A 3-story structure of the vertical attachment type. A crystal plate having predetermined crystal planes is generally used as a birefringent plate. Examples of the polymer film constituting the 1 / 4 wavelength plate include uniaxially stretched plastic films. The 1 / 4 wavelength plate has the function of transforming the polarization state of incident light from linear polarization to circular polarization. A uniaxially stretched polymer film having a predetermined thickness has a characteristic that the birefringence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com