Powder metallurgy press

A technology of powder metallurgy and press, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of unguaranteed accuracy, complex structure, high price, etc., to reduce the workload of design and production, reduce cost, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with the accompanying drawings, but the scope of protection claimed by the present invention is not limited to the scope mentioned in this embodiment.

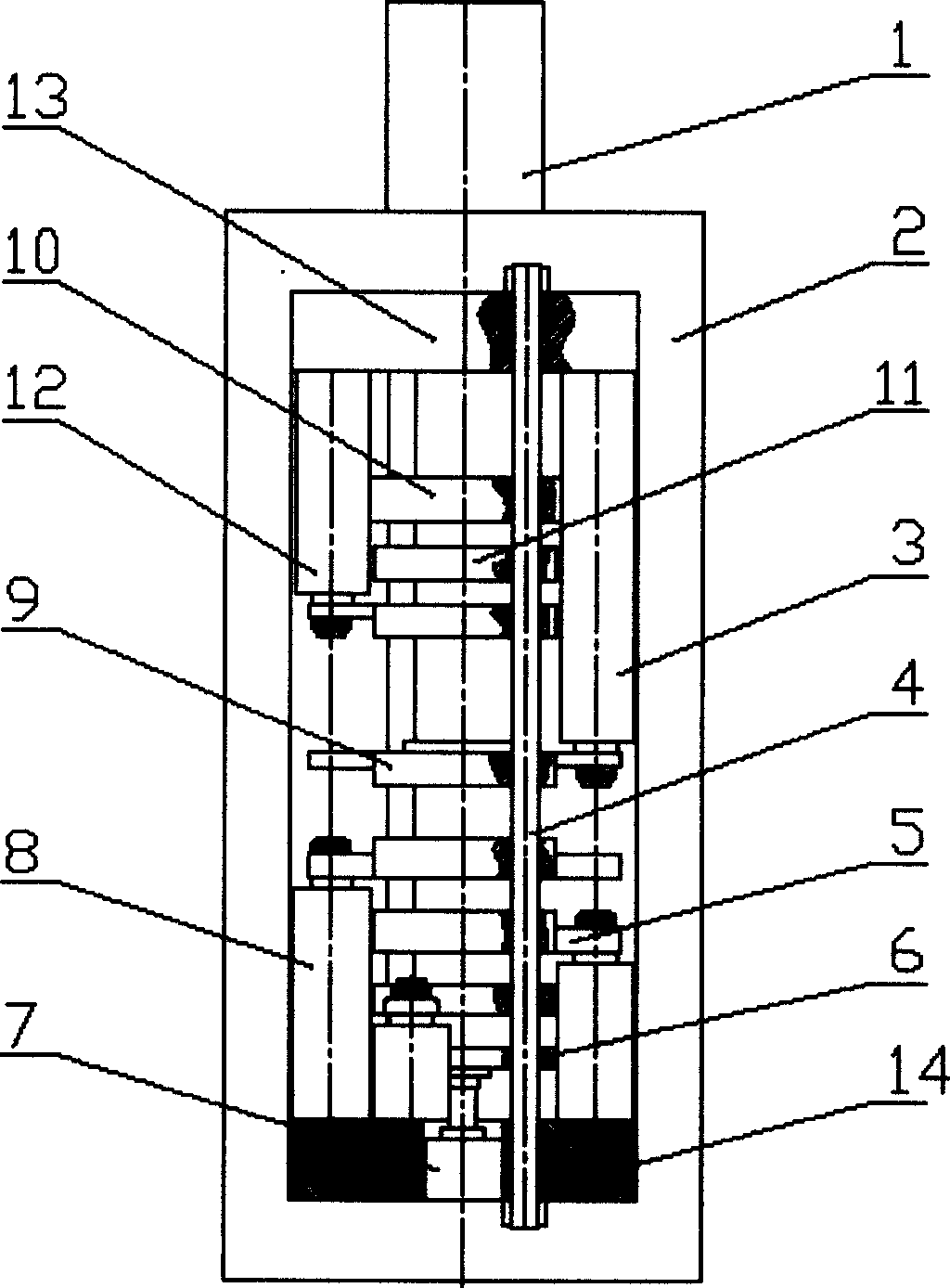

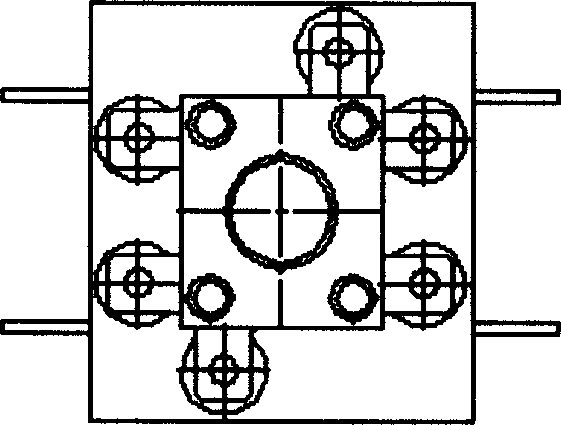

[0015] figure 1 As shown, the press includes the following parts: 1. Upper cylinder, 2. Frame, 3. Drive cylinder for die table, 4. Guide column, 5. Lower template, 6. Core rod template, 7. Core rod drive cylinder, 8. Lower template drive cylinder, 9. Mold platform, 10 upper beams, 11 upper formwork, 12 upper formwork drive cylinders, 13 top plate, 14 bottom plate. The mold base of this press adopts the upper two and lower three mold bases. Each layer of formwork and mold table is driven by two oil cylinders symmetrically arranged.

[0016] There are two upper templates 11, one is driven by two symmetrically arranged upper template driving cylinders 12, and the upper template driving cylinders 12 are suspended and installed on the upper part of the press; the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com