Full-automatic high speed piling and packing machine

A fully automatic, packaging machine technology, applied in the direction of packaging, wrapping paper, wrapping paper shrinkage, etc., can solve the problems of affecting the packaging effect, heat accumulation of sealing and cutting knives, poor cooling effect, etc., to reduce the possibility of burns and increase stability , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

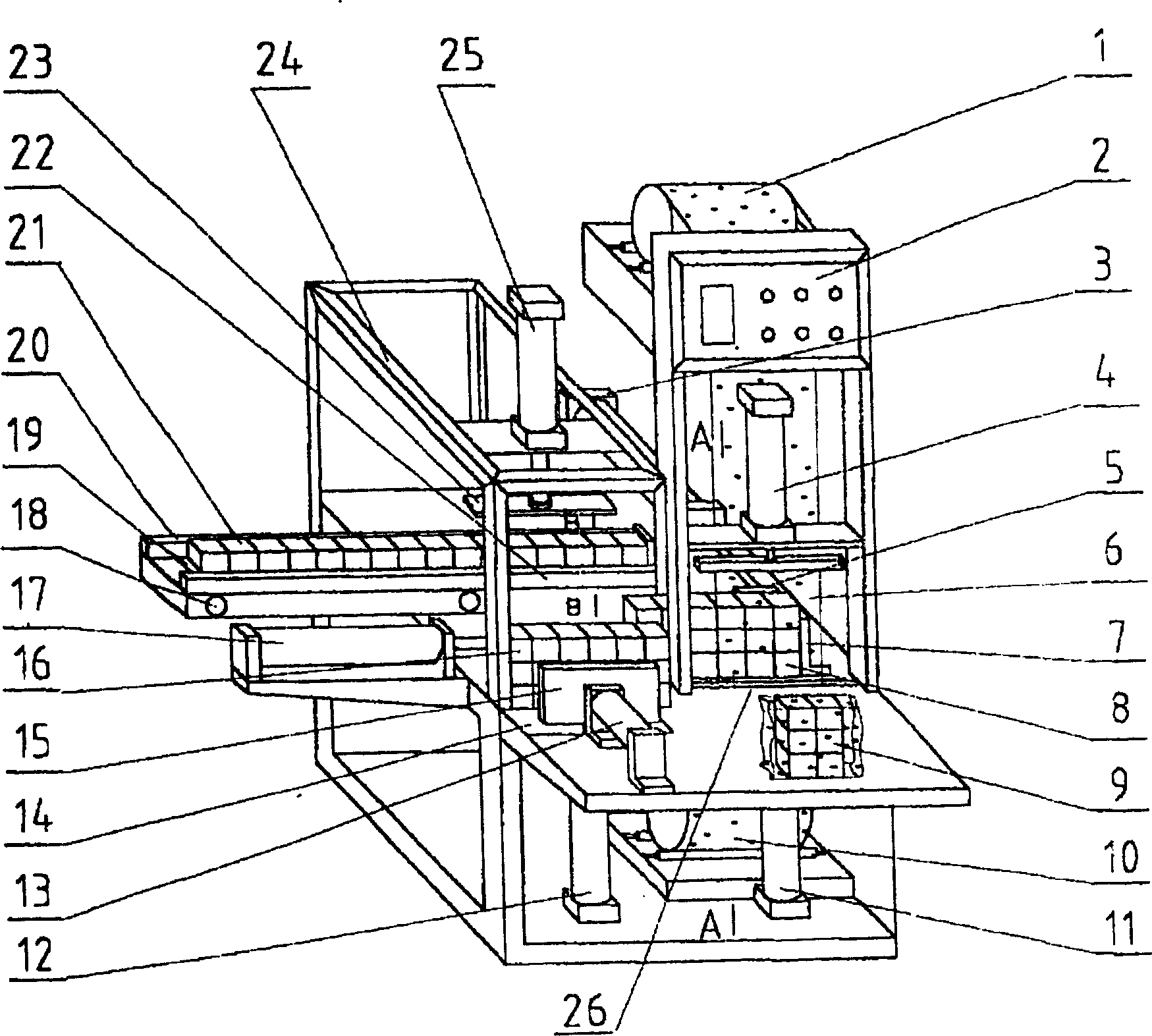

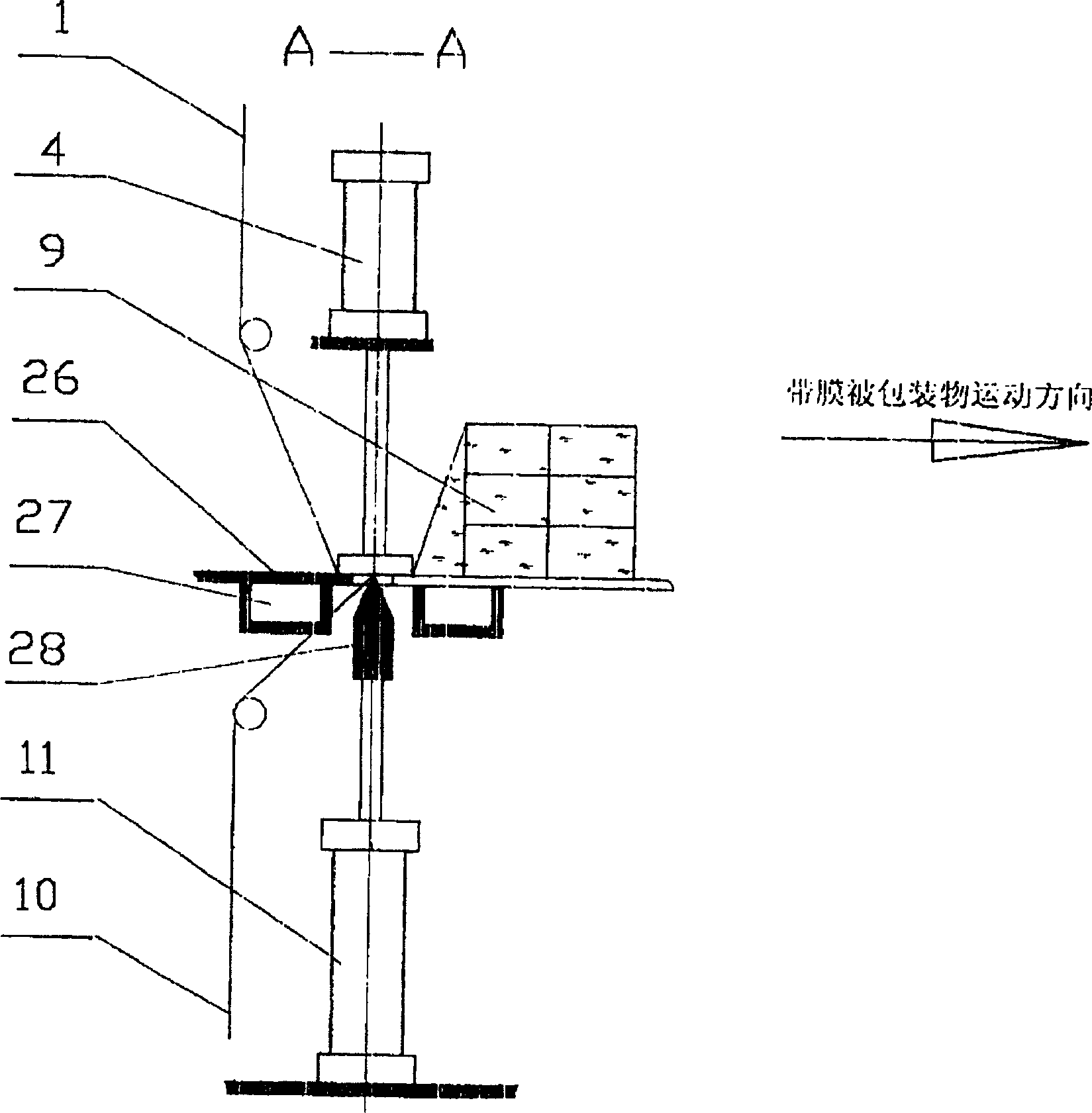

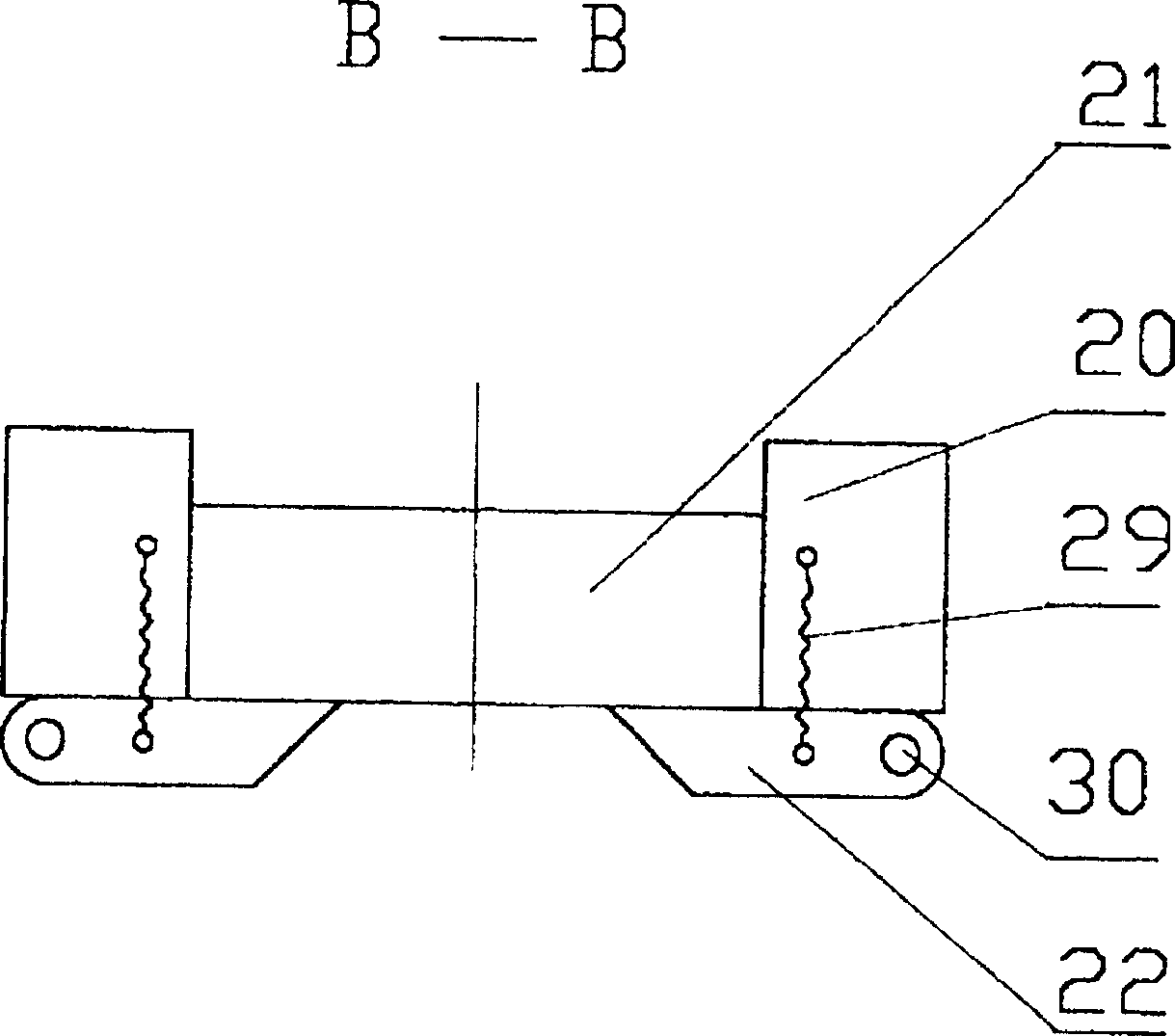

[0013] The working principle of the present invention will be described in detail below in conjunction with the accompanying drawings. Please see attached figure 1 , 2 3. The packaged object 21 moves forward through the conveyor belt 19. The conveyor belt is driven by the conveyor belt wheel shaft 18, and then the packaged object enters the pallet 22. After encountering the front baffle, the packaged object 21 stops moving. When the upper cylinder 25 moves downward, the packaged object 21 is driven by the upper cylinder push plate 23 connected to the upper cylinder 25 to move downward, so that the supporting plate 22 moves along the rotating shaft 30 respectively. Rotation on both sides (see image 3 ), so that the packaged object falls on the material receiving plate 14 of the waiting material receiving cylinder 12 that has begun to rise, and then the supporting plate 22 returns to the working state under the effect of the return spring 29, and the return spring is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com