Heat insulation parts for air conditioner branch pipe

A technology of branch pipes and branch parts, which is applied in the field of heat insulation components of air-conditioning branch pipes, can solve the problems of air-conditioning heat exchange efficiency reduction and condensed water, and achieve the goals of improving satisfaction, preventing condensed water, and improving heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

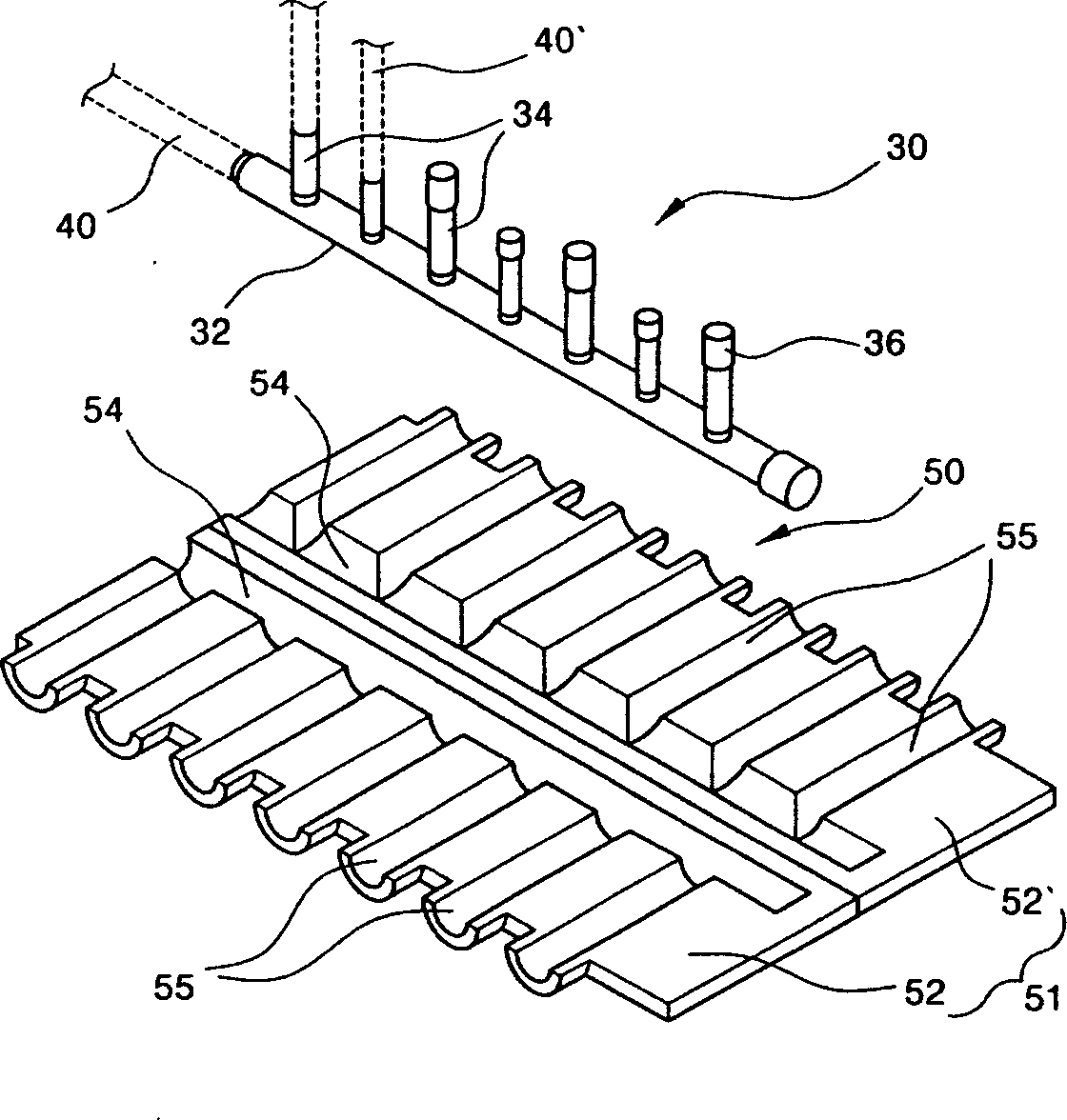

[0022] The heat insulation component of the air-conditioning branch pipe of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

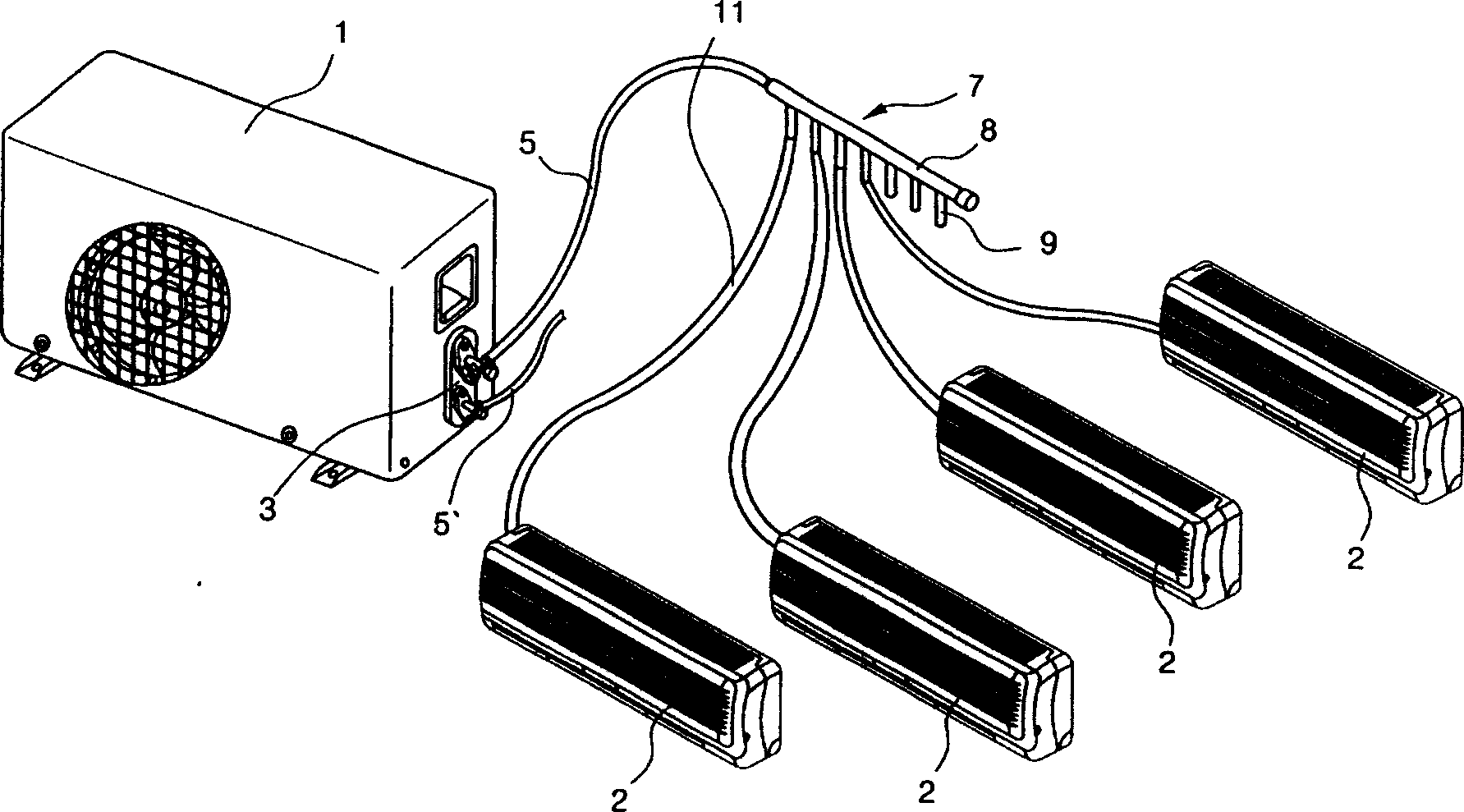

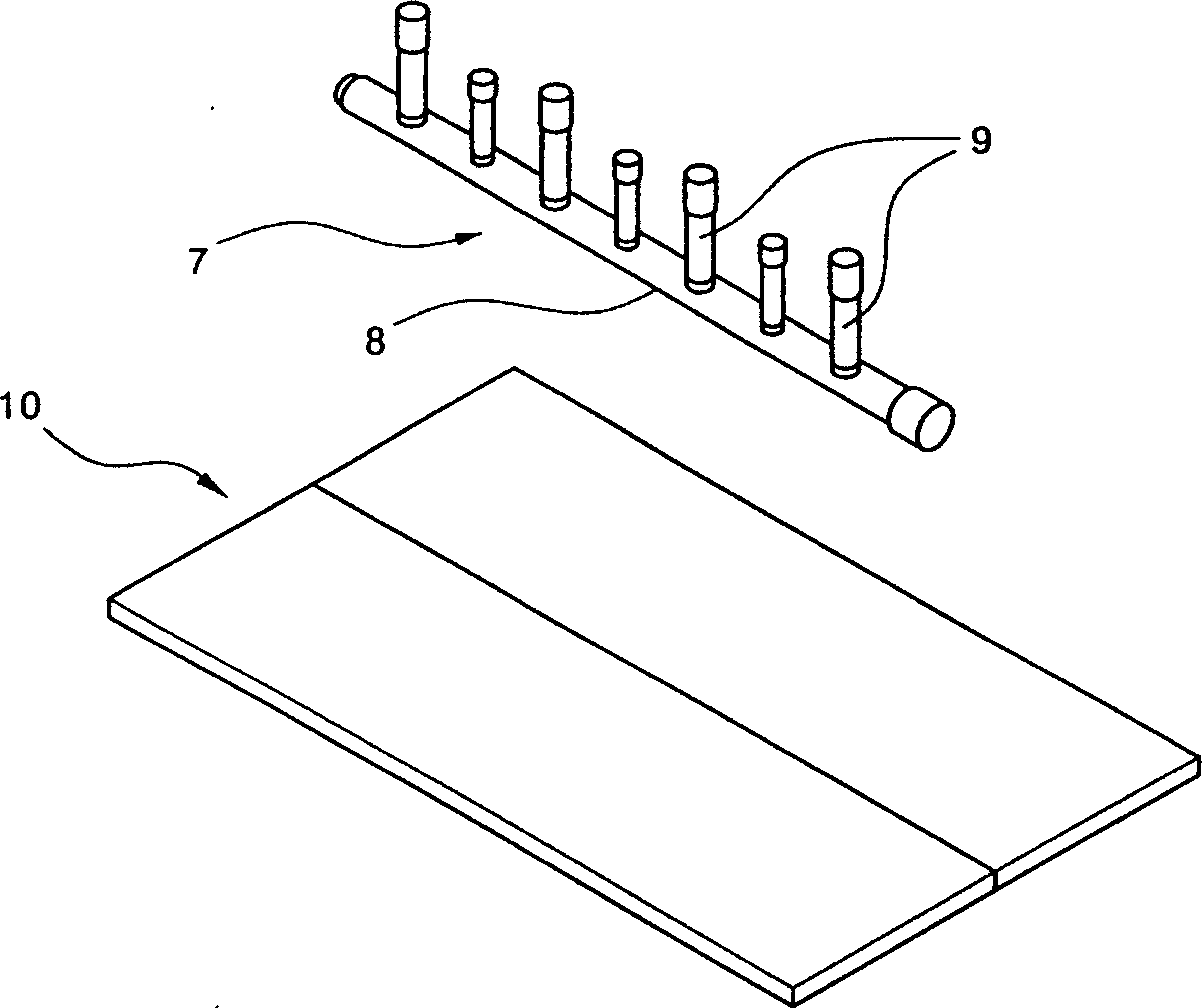

[0023] image 3 It is an exploded view of an embodiment of the air-conditioning branch pipe thermal insulation component of the present invention. As shown in the figure, the branch pipe connects one flow path to multiple flow paths, so that the refrigerant can flow from one flow path to multiple flow paths, and from multiple flow paths to one flow path.

[0024] The branch pipe 30 is composed of a main pipe 32 and a branch portion 34 . In this embodiment, the main pipe is a round pipe with a certain length, one end of which is connected with the connecting pipe 40 .

[0025] Branches 34 are arranged successively on the outer surface of the main pipe 32 to be provided with a plurality, and different diameters can be selected according to the capacity of the indoor unit, and are als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com