Axial gap brushless DC motor

A brush DC motor, axial air gap technology, applied in synchronous motors with stationary armature and rotating magnets, electrical components, electromechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

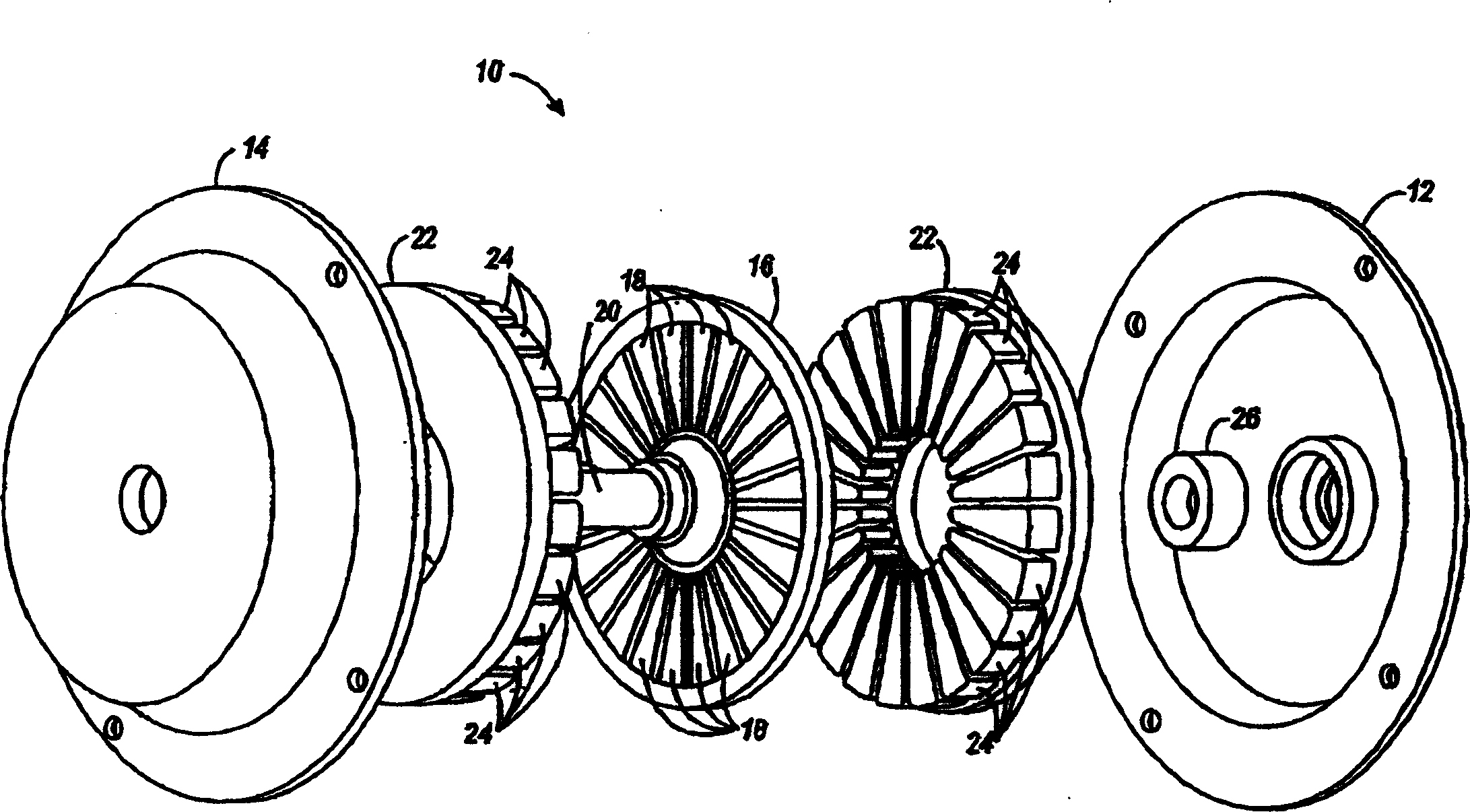

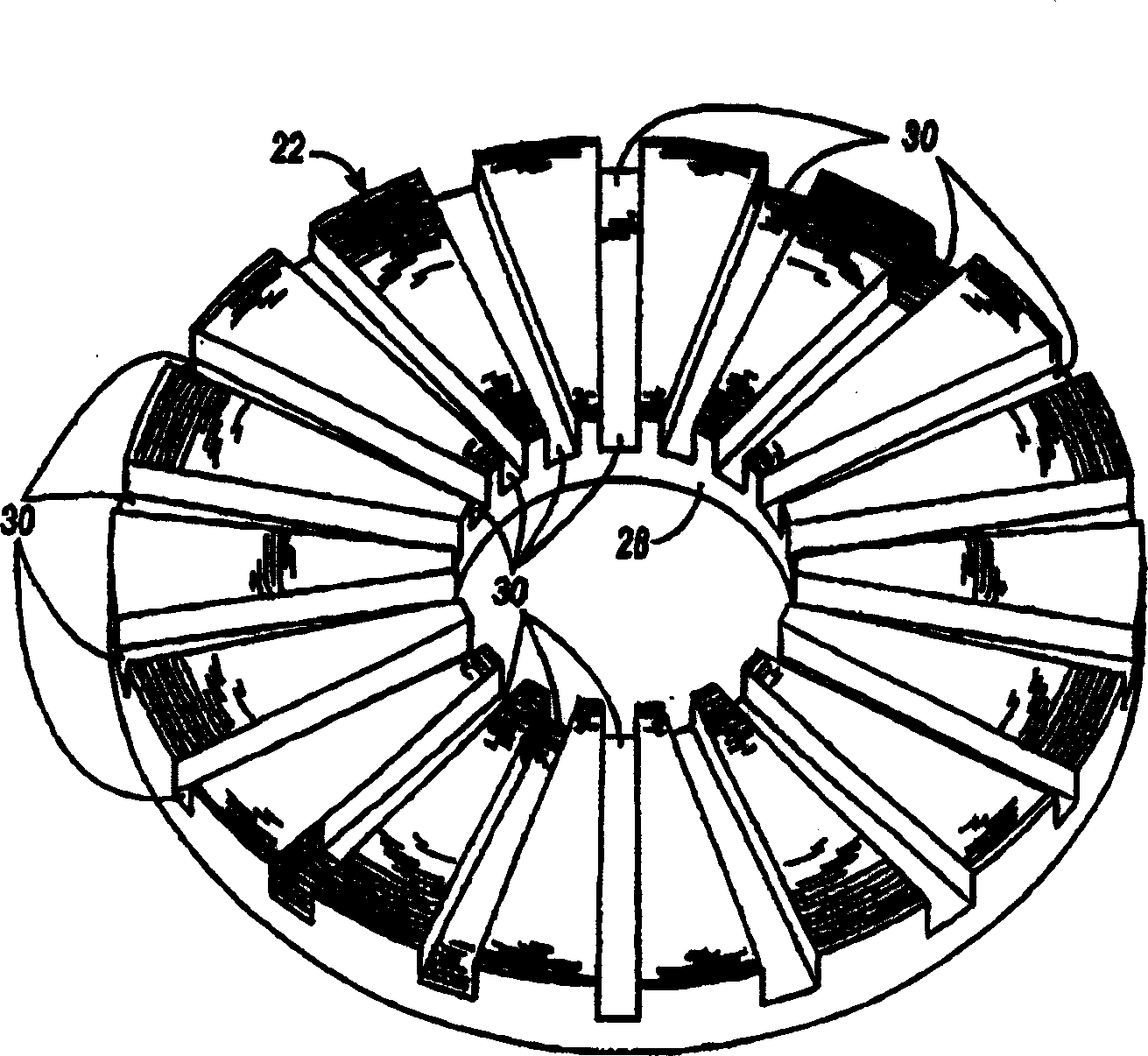

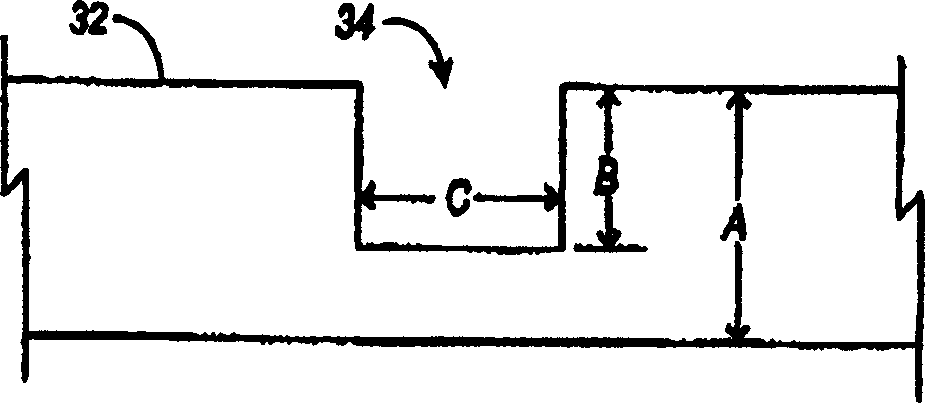

[0025] In general, the present invention provides a dual stator axial air gap brushless DC motor (eg, motor, alternator, etc.). The stator windings are embedded in slots formed on the stator, which has many advantages. The motor of the present invention is highly efficient and weighs significantly less than commercially available motors of the prior art. Because this design minimizes the use of expensive magnets and magnets, the weight savings translates into cost savings. The motor of the present invention has a high number of poles, with the result that a low speed, high torque motor is obtained. High power and high torque density allow the motor to directly drive loads in many applications, such as light vehicle traction drives. When complex converters are used, the motor of the present invention operates over a wide speed range without or minimizing the need for scaling.

[0026] figure 1 is an exploded perspective view of the dual stator axial air gap brushless DC mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com