High-strength stainless steel sheet and method for manufacturing the same

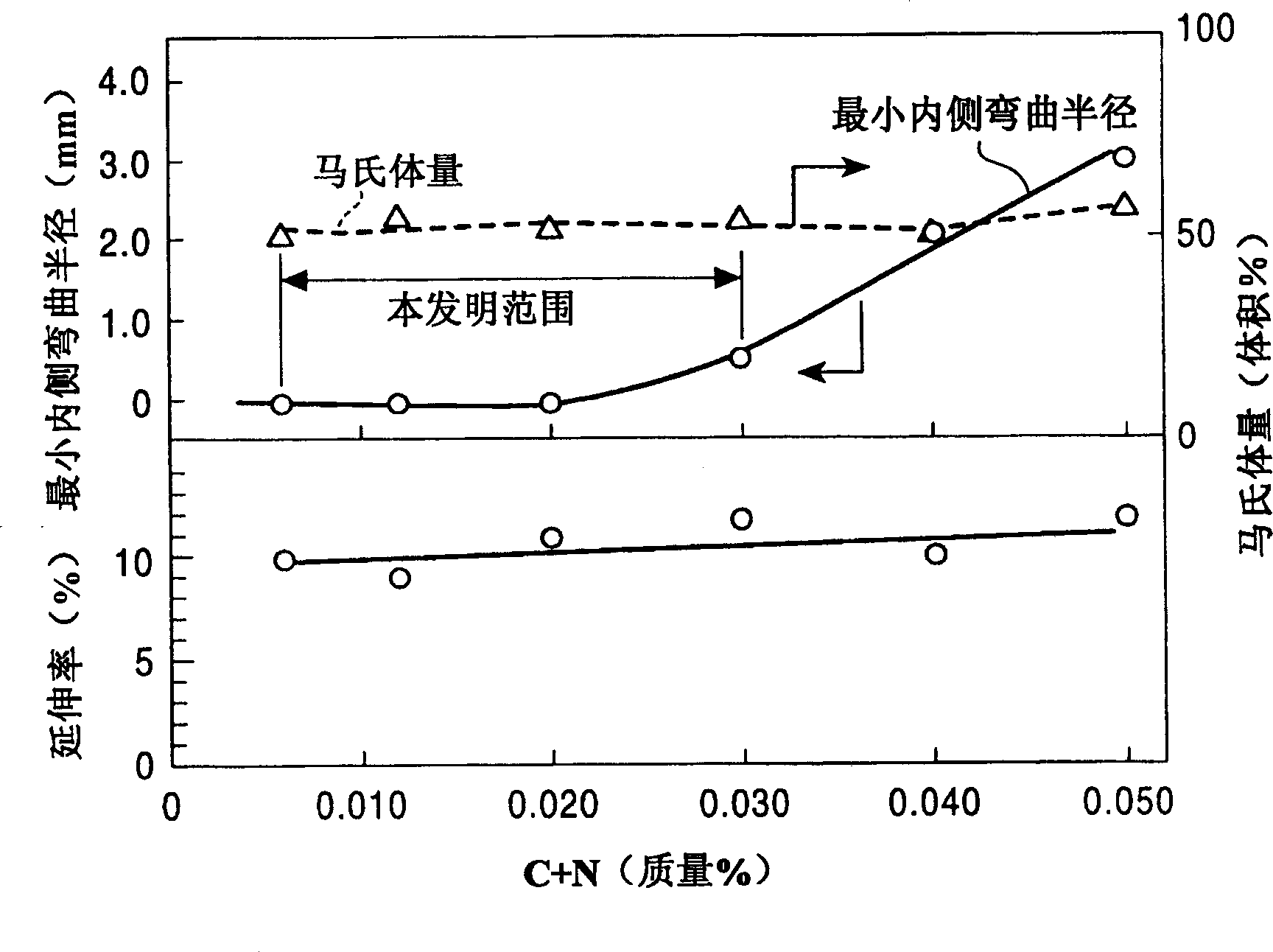

A technology of stainless steel plate and manufacturing method, which is applied in the direction of manufacturing tools, building reinforcements, building structures, etc., which can solve the problems of high manufacturing cost, insufficient stamping formability of welded parts, and unfavorable guarantee of rigidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

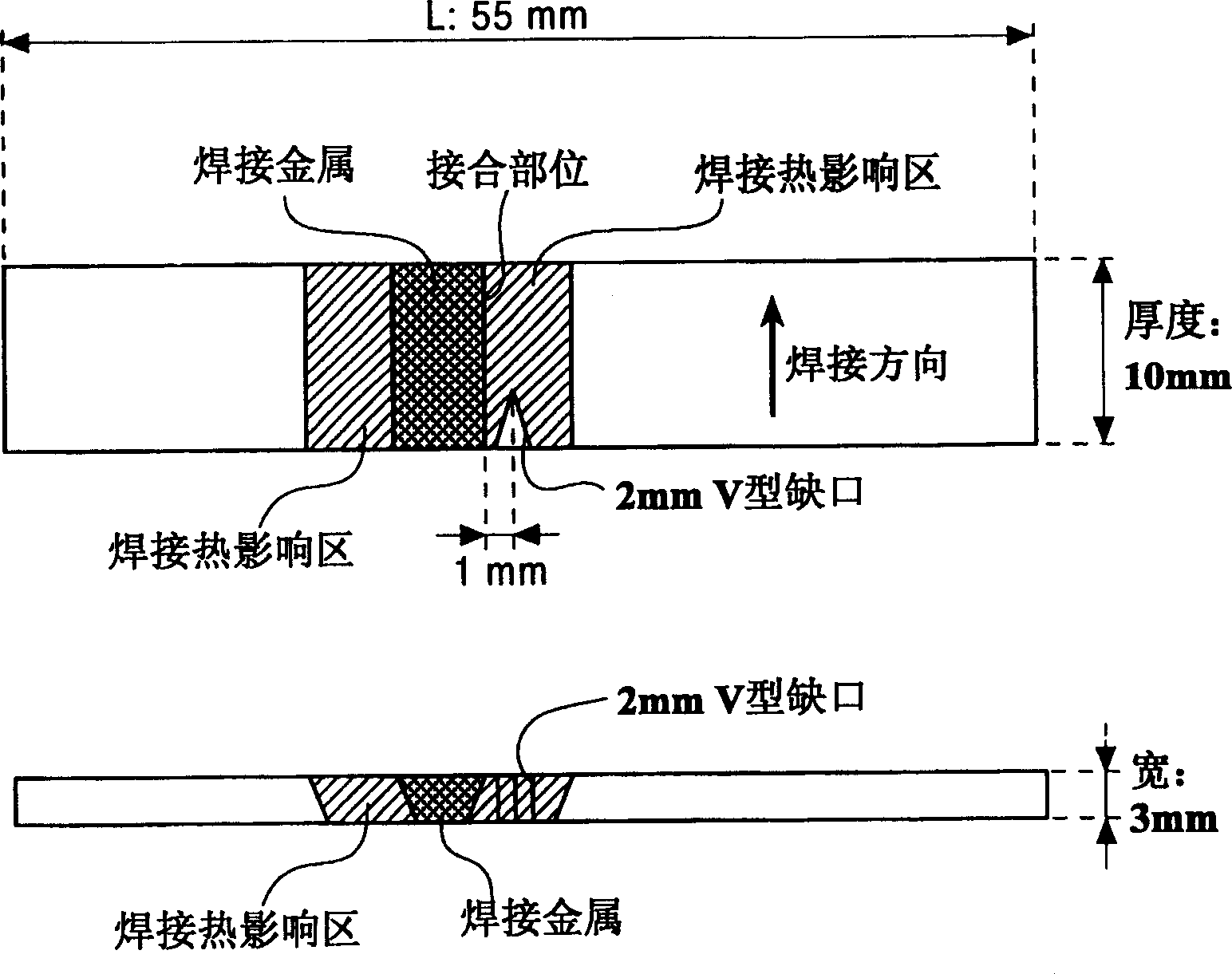

[0155] With the stainless steel plate of composition shown in table 1 and table 2 as raw material, the batch type annealing furnace of condition shown in table 3 and table 4 is carried out finished product heat treatment with this raw material, pickling then. (1) Observation of metal structure, (2) Tensile test, (3) Corrosion test, (4) Bending test, (5) Welding heat-affected zone toughness test was carried out on the obtained steel plate with plate thickness t=3mm. The test method is as follows. The hot-rolled steel sheet as the raw material is manufactured by heating a 100kgf steel ingot melted in a high-frequency furnace to 1200°C with the composition shown in Tables 1 and 2, and hot-rolling it to a thickness (t) of 3 mm with a reversing rolling mill.

[0156] (1) Observation of metal structure

[0157] Take the metal structure observation test piece (t (original thickness) × 10mm × 10mm each 1 piece) from the obtained steel plate, and use Murakami reagent (alkaline solutio...

Embodiment 2

[0172] Next, the characteristics of the cold-rolled steel sheet were studied. The 3 mm thick hot-rolled steel sheet No. 1K in Table 1 of Example 1 above was annealed at 700° C. for 10 hours and then slowly cooled, and then the scale was removed by pickling. Next, the hot-rolled and annealed steel plate is cold-rolled to a plate thickness of 1.5mm with a reversing rolling mill, held at 1000°C for 30s, cooled at a rate of 15°C / s to the cooling stop temperature of 100°C, and then dipped to 60°C. A mixed acid (nitric acid 10% by mass + hydrofluoric acid 3% by mass) was used to descale the scale to obtain a cold-rolled steel sheet having a thickness t=1.5 mm. The same test as the hot-rolled steel sheet of Example 1 above was carried out.

[0173] However, TIG welding (current 95A, voltage 11V, welding speed 400mm / min, shielding gas on the surface (electrode) side: 20l / min, backside 10l / min) was used for welding to study the toughness of the welded part. As a result, the volume fr...

Embodiment 3

[0175] With the stainless steel cold-rolled steel sheet of composition shown in Table 5 and Table 6 as raw material, carry out finished product heat treatment with batch-type annealing furnace with the conditions shown in Table 7 and Table 8 to this raw material, and carry out pickling. The same (1) metal structure observation, (2) tensile test, and (3) corrosion test as in Example 1 were performed on the obtained steel plate having a plate thickness of t=0.7 mm. As the cold-rolled steel sheet as the raw material, a 100kgf steel ingot whose composition is shown in Table 5 and Table 6 is dissolved in a high-frequency furnace is heated to 1200°C, hot-rolled to 3mm with a reversing rolling mill, and then slowed down at 700°C for 10 hours. After cold annealing and pickling to remove scale, the hot-rolled steel sheet was cold-rolled to a thickness of 0.7 mm with a reversing rolling mill.

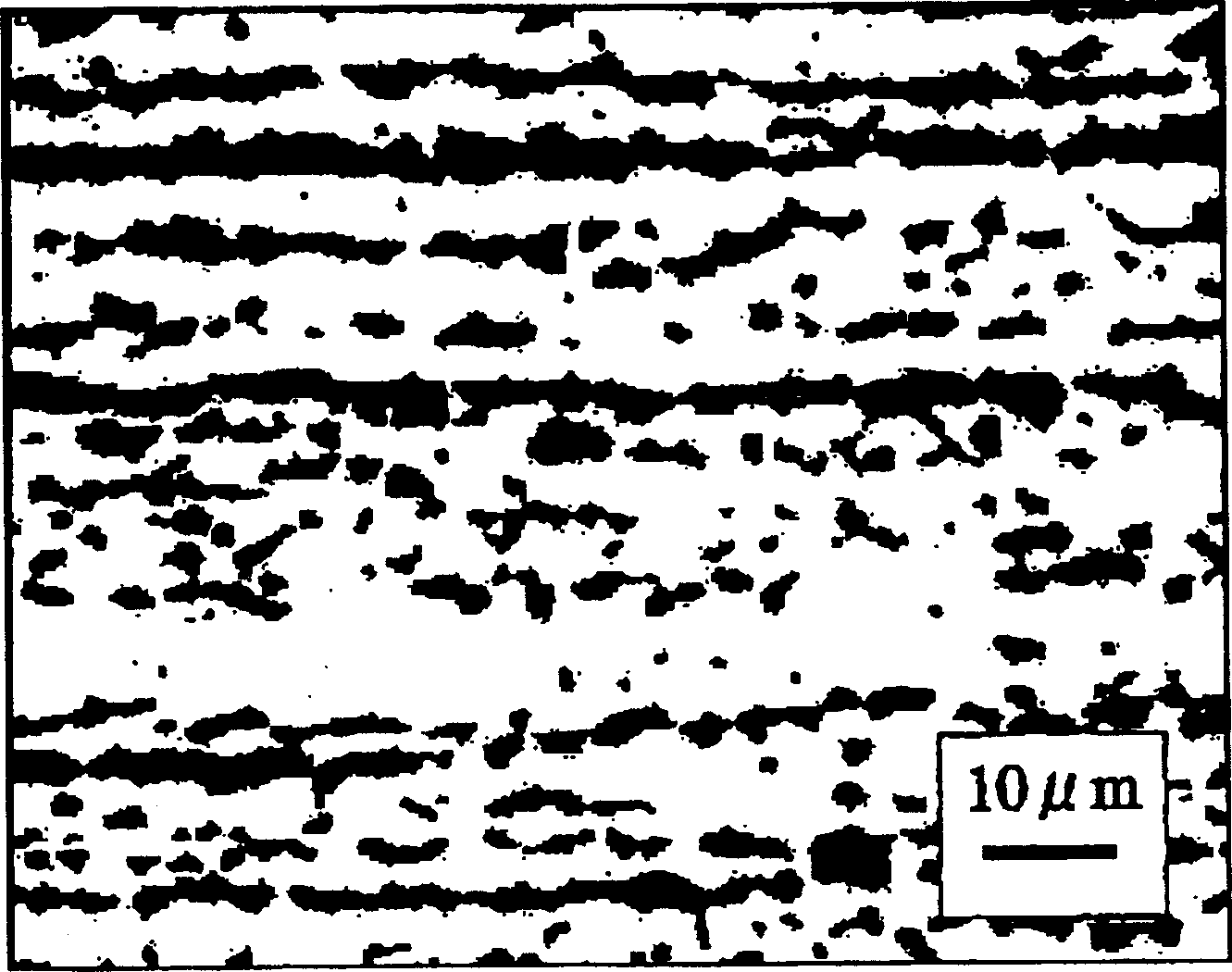

[0176] As an example of metal structure observation of (1), figure 2 An optical microscope ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap