Damper for washing machine

A shock absorber and washing machine technology, which is applied to other washing machines, friction dampers, washing devices, etc., can solve problems such as washing machine movement, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

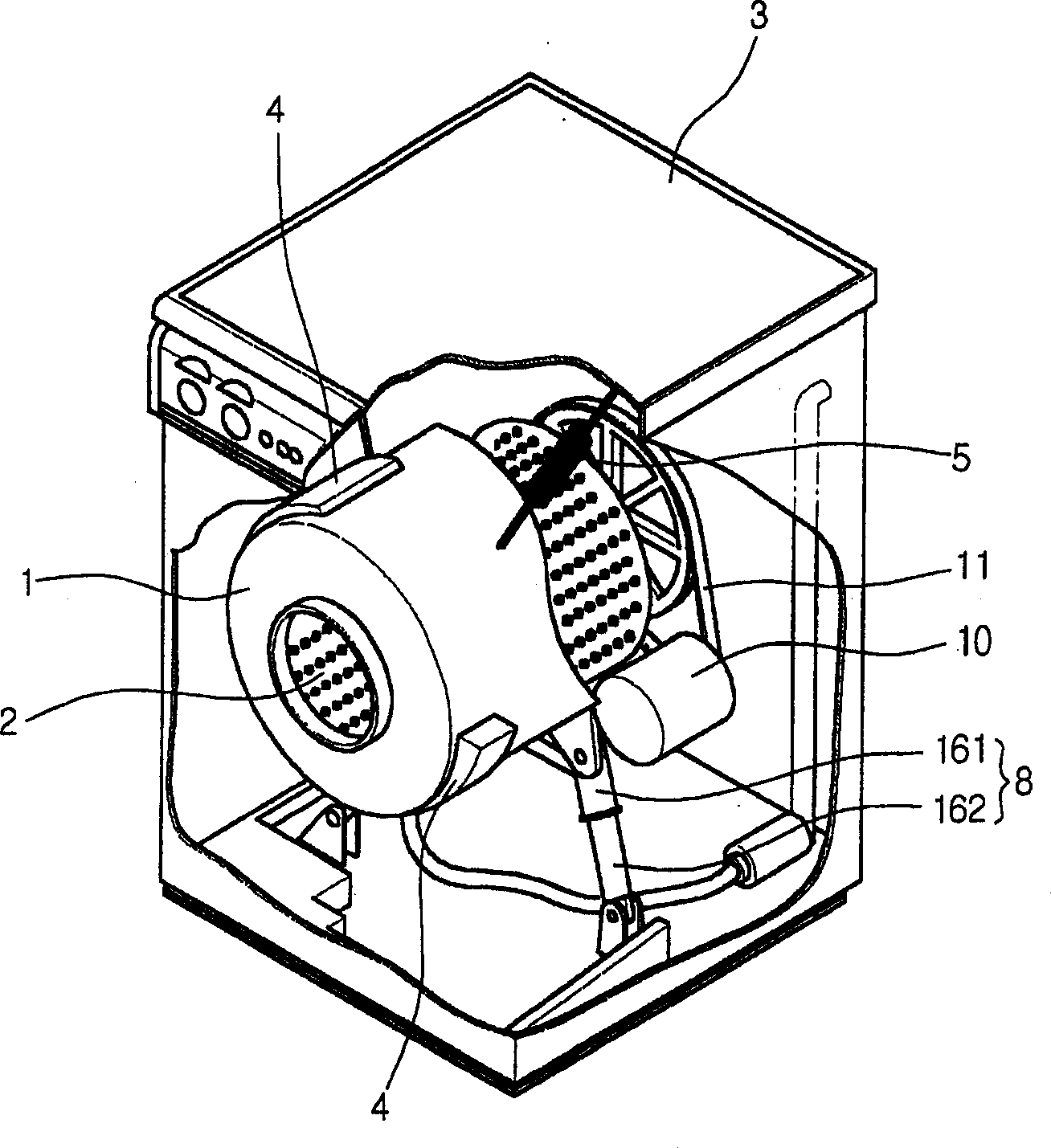

[0035] figure 1 is a perspective view of a drum type washing machine employing the shock absorber according to the first embodiment of the present invention.

[0036] As shown in the figure, the drum-type washing machine includes a casing 3, a tub 1 for holding water arranged in the casing 3, a drum 2 for accommodating clothes in the tub 1, and a drive motor 10 for rotating the drum 2 at the back of the tub 1. .

[0037] The operation of the drum type washing machine will be described below.

[0038] The rotational force of the driving motor 10 is transmitted to the drum 2 through the belt 11 . When the drum 2 rotates, the clothes placed in the drum 2 rotate together with the drum 2 . At this time, since the drum 2 rotates at a relatively low speed, the clothes rise by the rotating force of the drum, fall down due to gravity, and collide with the water contained in the tub 1 . Through the impact force of clothes and water, the dirt on clothes is washed. Although in this e...

no. 2 example

[0062] Figure 7 and Figure 8 A second embodiment of the invention is shown. Particularly, Figure 7 is a sectional view of a shock absorber according to a second embodiment of the present invention, Figure 8 is a sectional view showing the vibration damping operation.

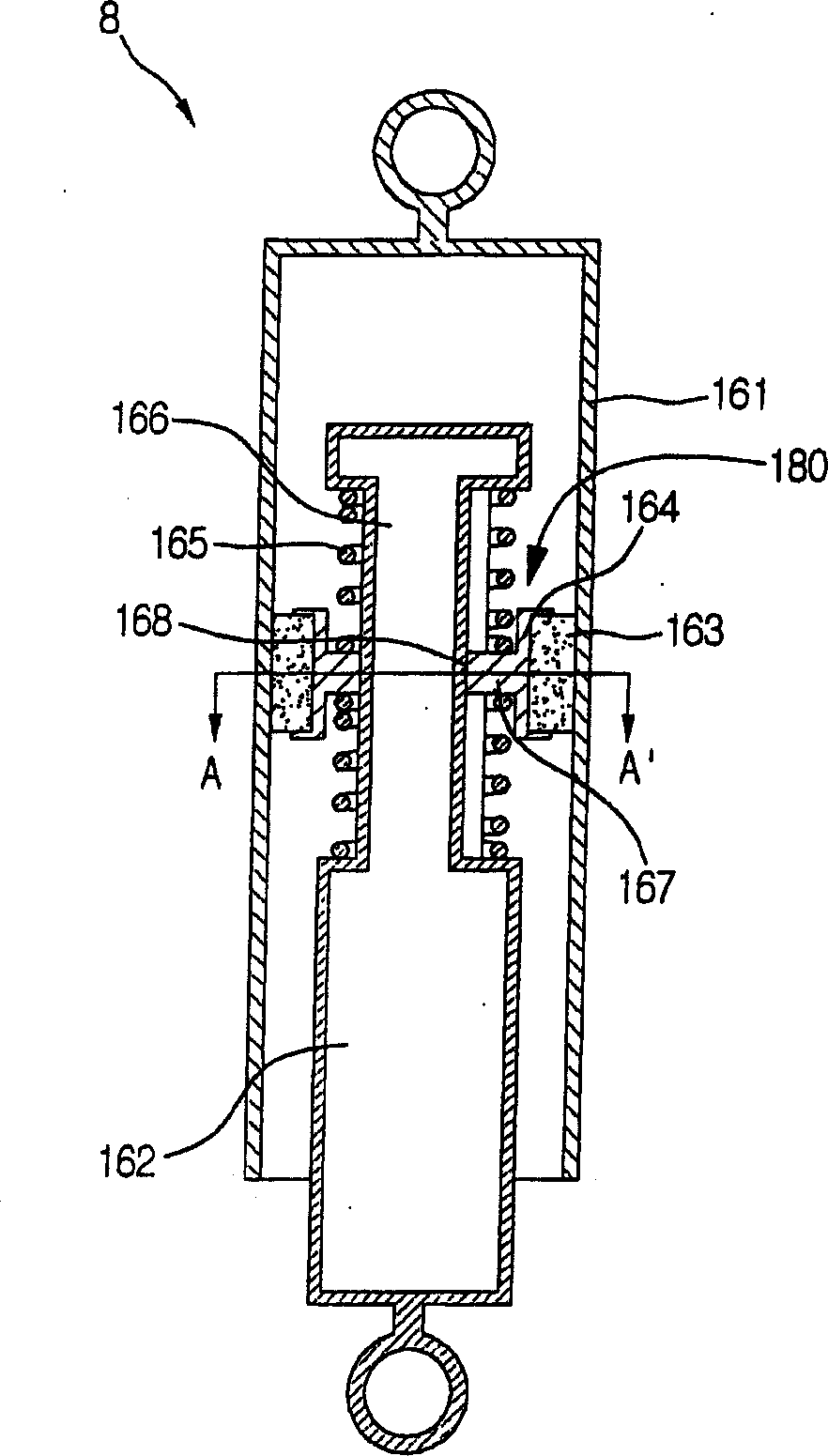

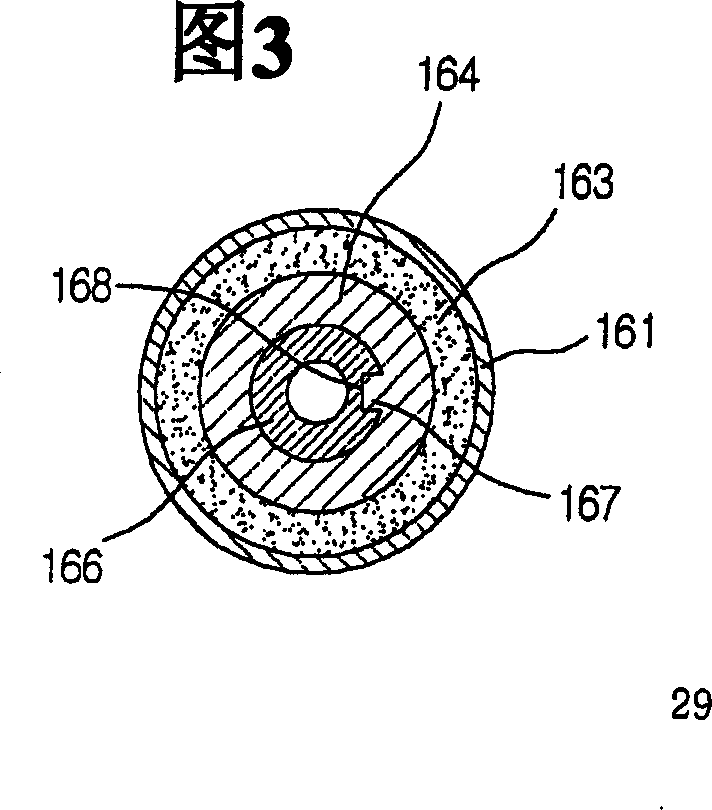

[0063] refer to Figure 7 , the shock absorber 8 of this embodiment is designed to include: a hollow cylinder 261; a rod 262 with one end inserted into the cylinder 261; a sliding rod 267 integrated with one end of the rod 262; A slidable pad support 264 that is installed on the outside of the slide bar 267 and separated therefrom; a vibration damping pad 263 formed on the outer circumference of the pad support 264 makes the frictional force work by friction with the inner circumference of the cylinder 261; , Two springs 265, 266 are respectively connected between the pad support 264 and the rod 262, between the pad support 264 and the slide bar 267. The first and second springs 265 , 266 limit any rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com