Control device with shift position detector, and power train with the control device

一种动力传动系、检测装置的技术,应用在传动装置控制、带有齿的元件、皮带/链条/齿轮等方向,能够解决没有做到ECU结构充分紧凑化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0142] Hereinafter, the preferred modes of implementing the present invention will be described in conjunction with the accompanying drawings.

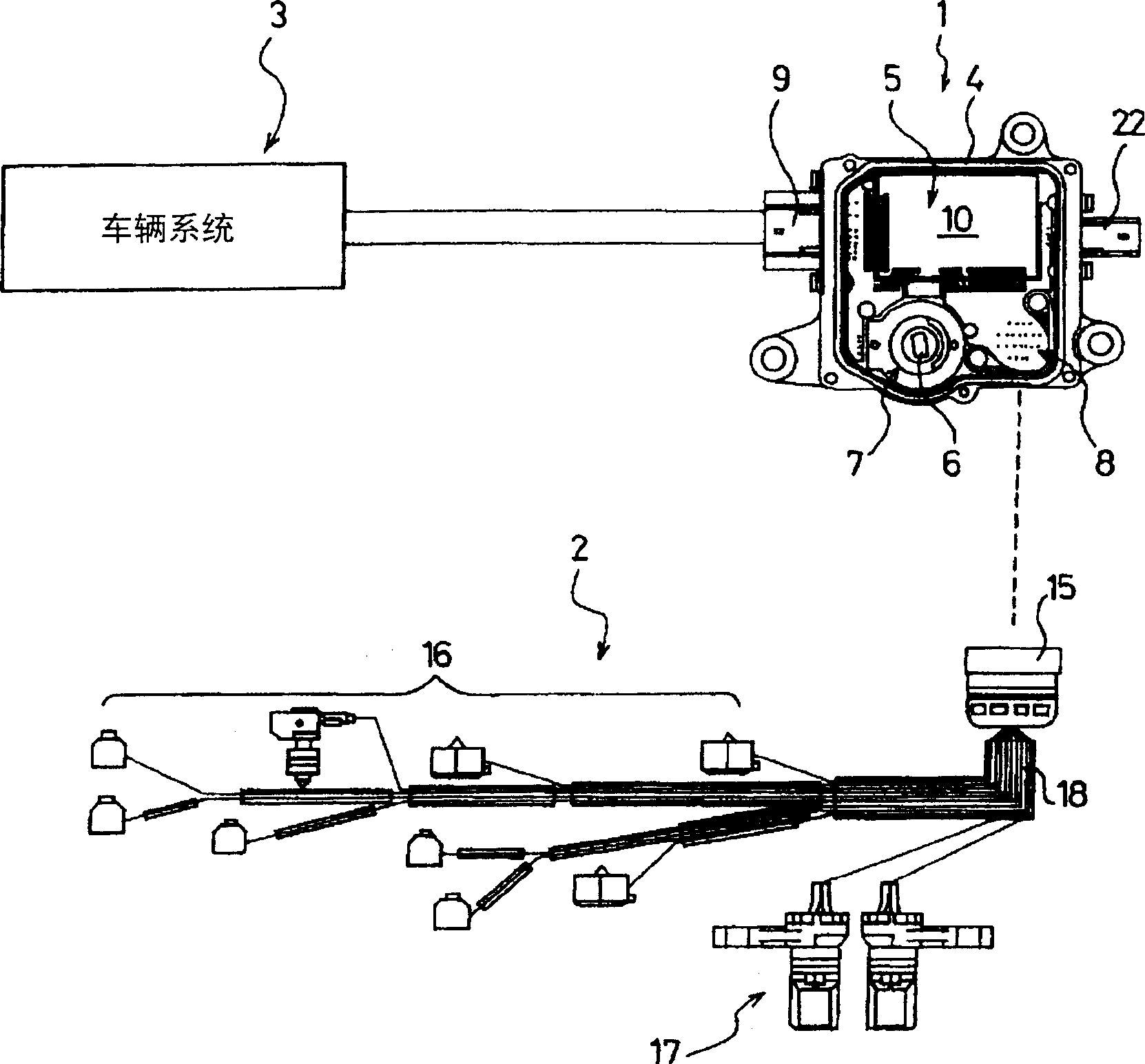

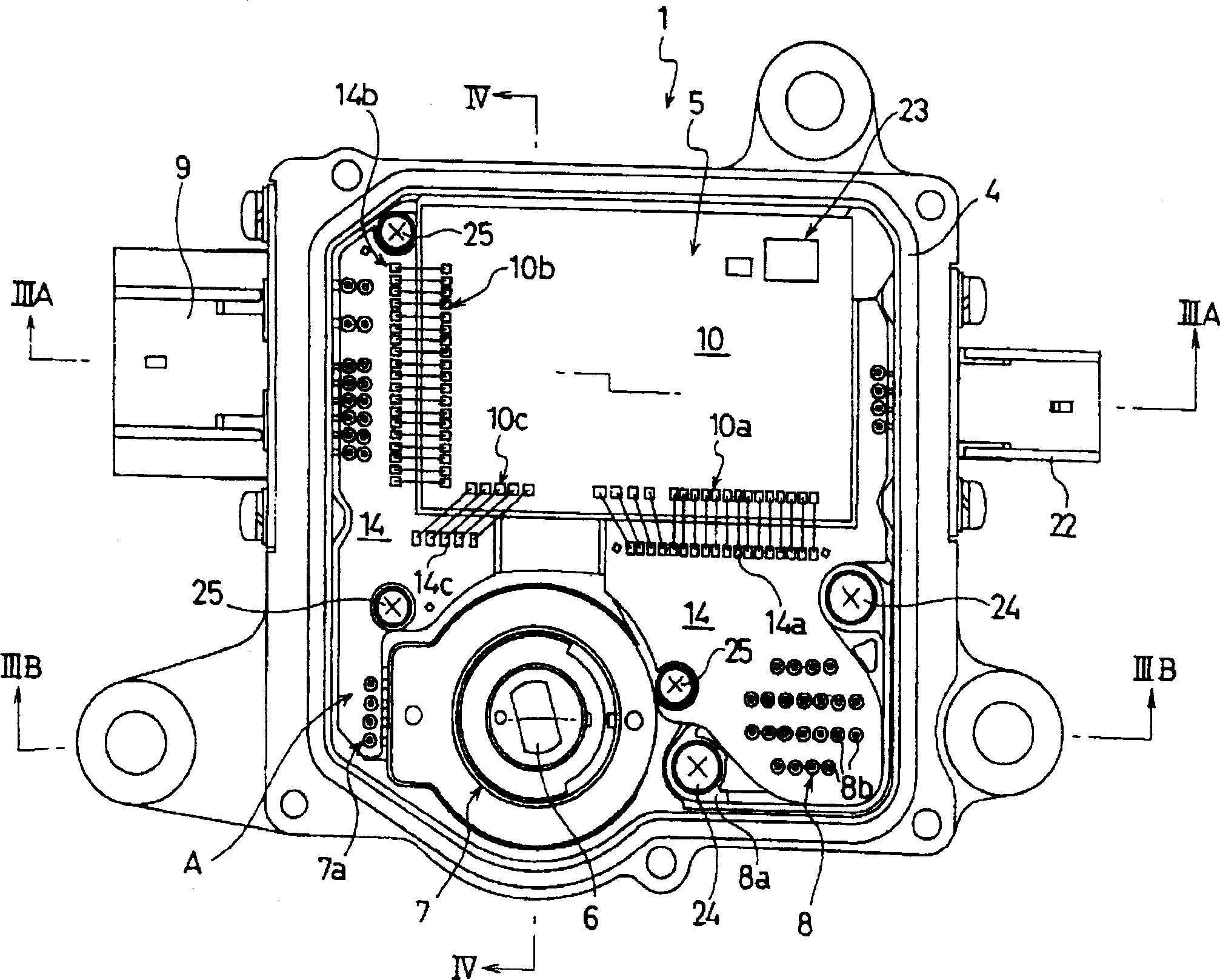

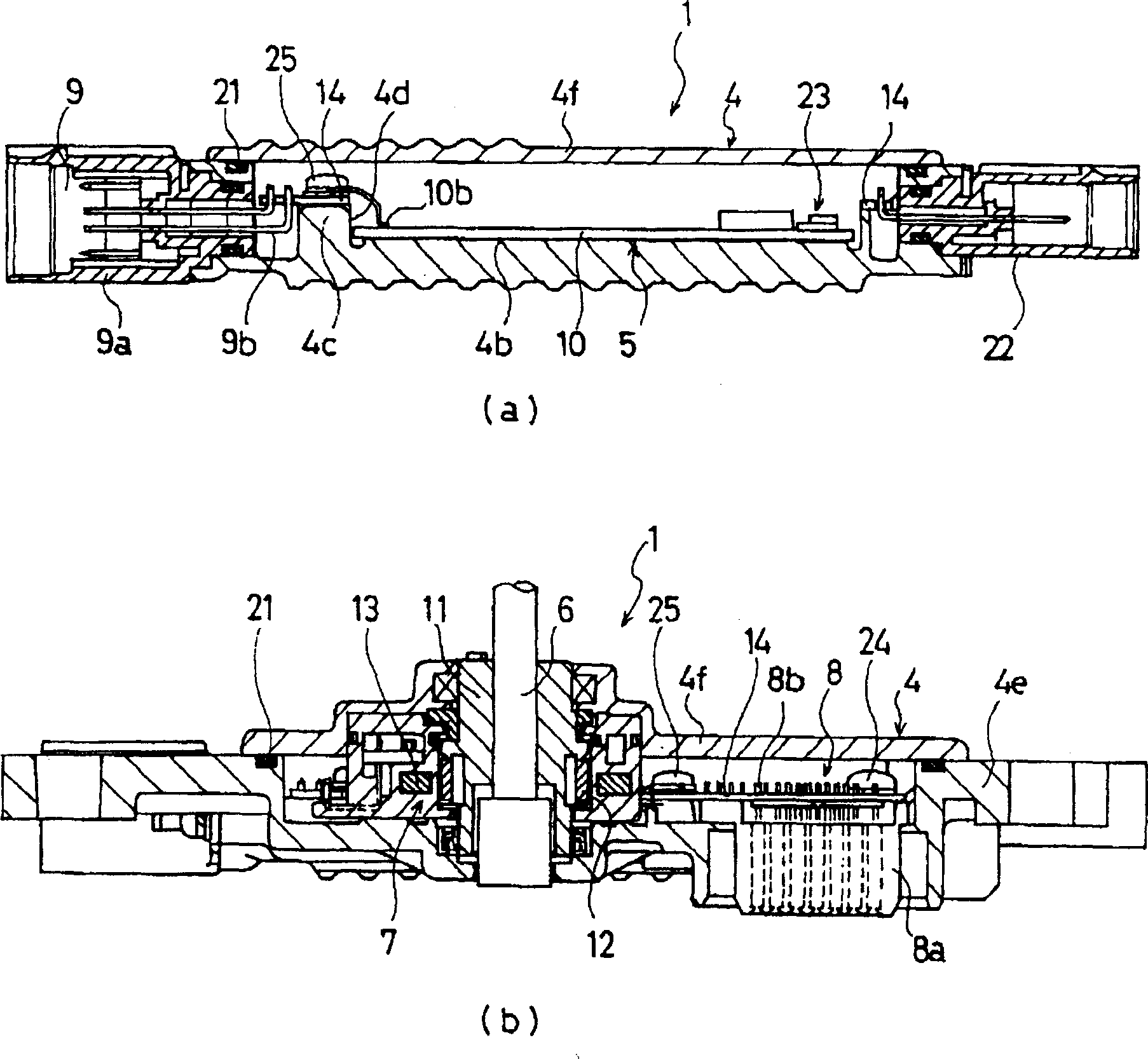

[0143] figure 1 A schematic diagram showing the electrical connection structure in the A / T of one of the power trains according to the first embodiment of the control device with the shift position detection device according to the present invention, figure 2 A plan view showing the control device with the shift position detection device of the first example, image 3 express figure 2 Sectional view along line III-III, Figure 4 It shows the schematic diagram of the control device with the shift position detection device of the first example, (a) is figure 2 The sectional view along line IV-IV in (b) is the partially enlarged sectional view in (a). Here, the shift positions refer to: for example, park gear (P), reverse gear (R), neutral gear (N), drive gear (D) and the like. and also, Figure 4 (a) and (b) show the arrangeme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com