Two-way through flow/axial flow pump

An axial flow pump and pump body technology, applied in the field of two-way water supply in pumping stations, can solve problems such as the appearance of guide vanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

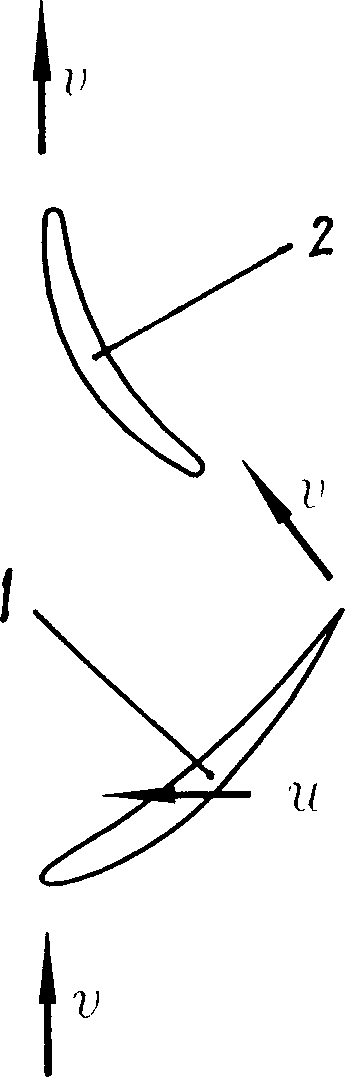

[0031] Figure 5 Represents the semi-movable guide vane of the present invention, which includes a guide vane fixed part 5 and a guide vane rotatable part 6, the guide vane fixed part is cast or welded with the inner and outer casings or integrated, the guide vane rotatable part is separate, and its end The portion has a rotating shaft 7.

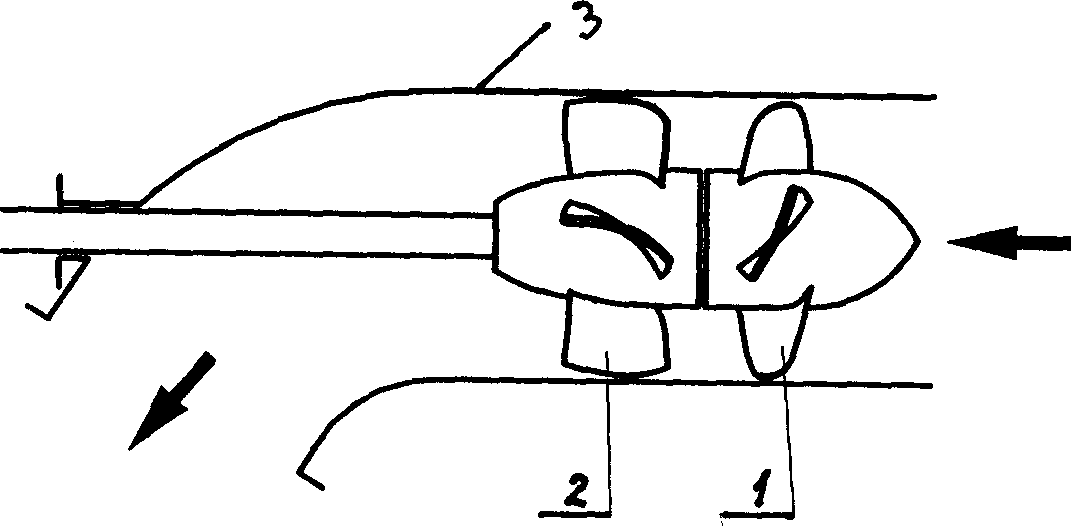

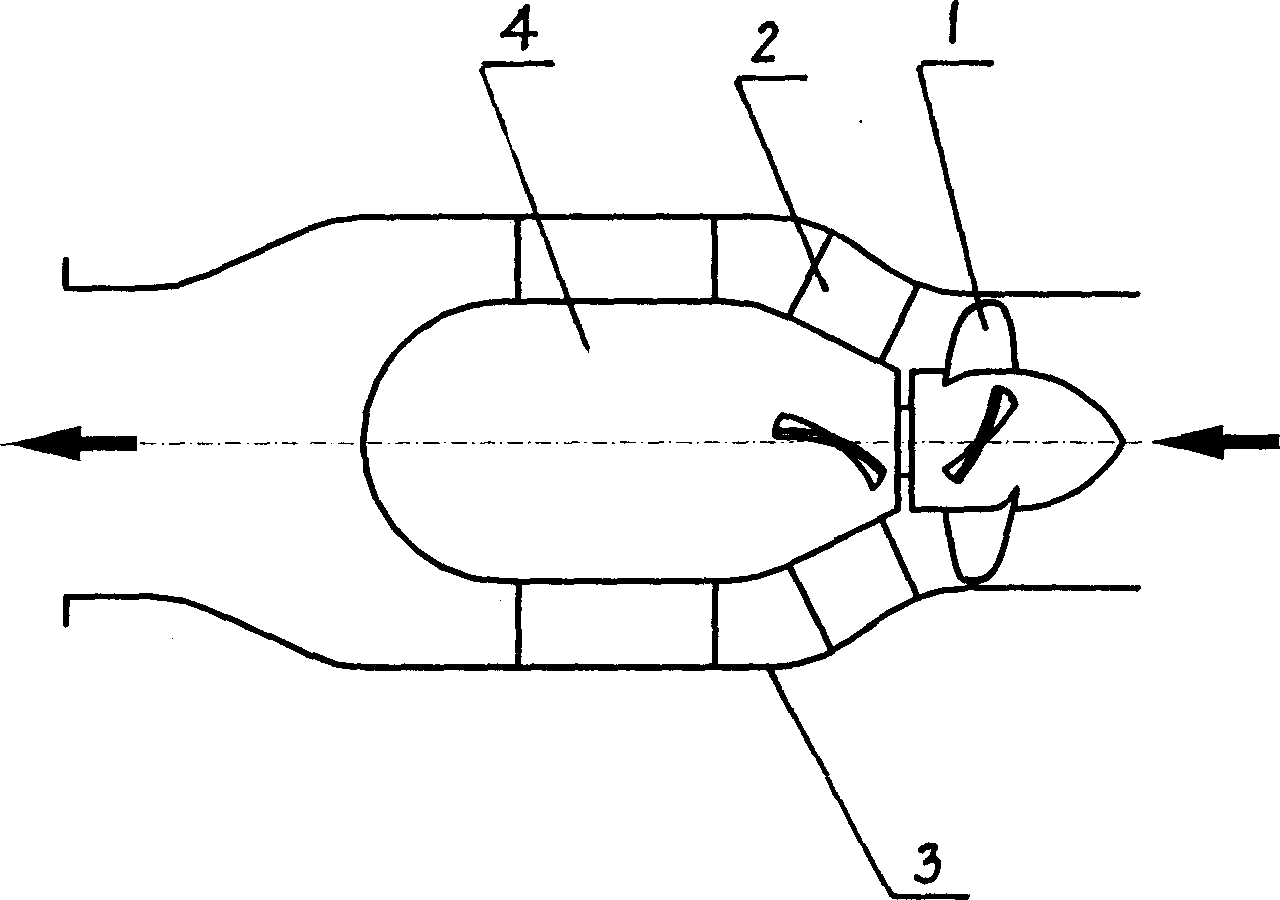

[0032] Figure 6 In the bidirectional axial flow pump shown, the impeller 1 in the pump body 3 is equipped with front and rear guide vanes respectively in the front and back axial directions, and they are evenly arranged in the radial direction, and each front guide vane and rear guide vane are composed of Figure 5 The shown semi-movable guide vane is formed, and the rotating shaft 7 at the end protrudes from the pump body 3 and can be connected with the guide vane rotating mechanism.

[0033] Figure 7 A guide vane rotation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com