Roll plasticizing shaping method of large plastic product and its special mould

A technology of plastic products and rotational molding, applied in the direction of coating, etc., can solve the problems of molten material flow, affecting the strength of products, etc., to achieve the effect of good quality, overcoming adverse effects, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

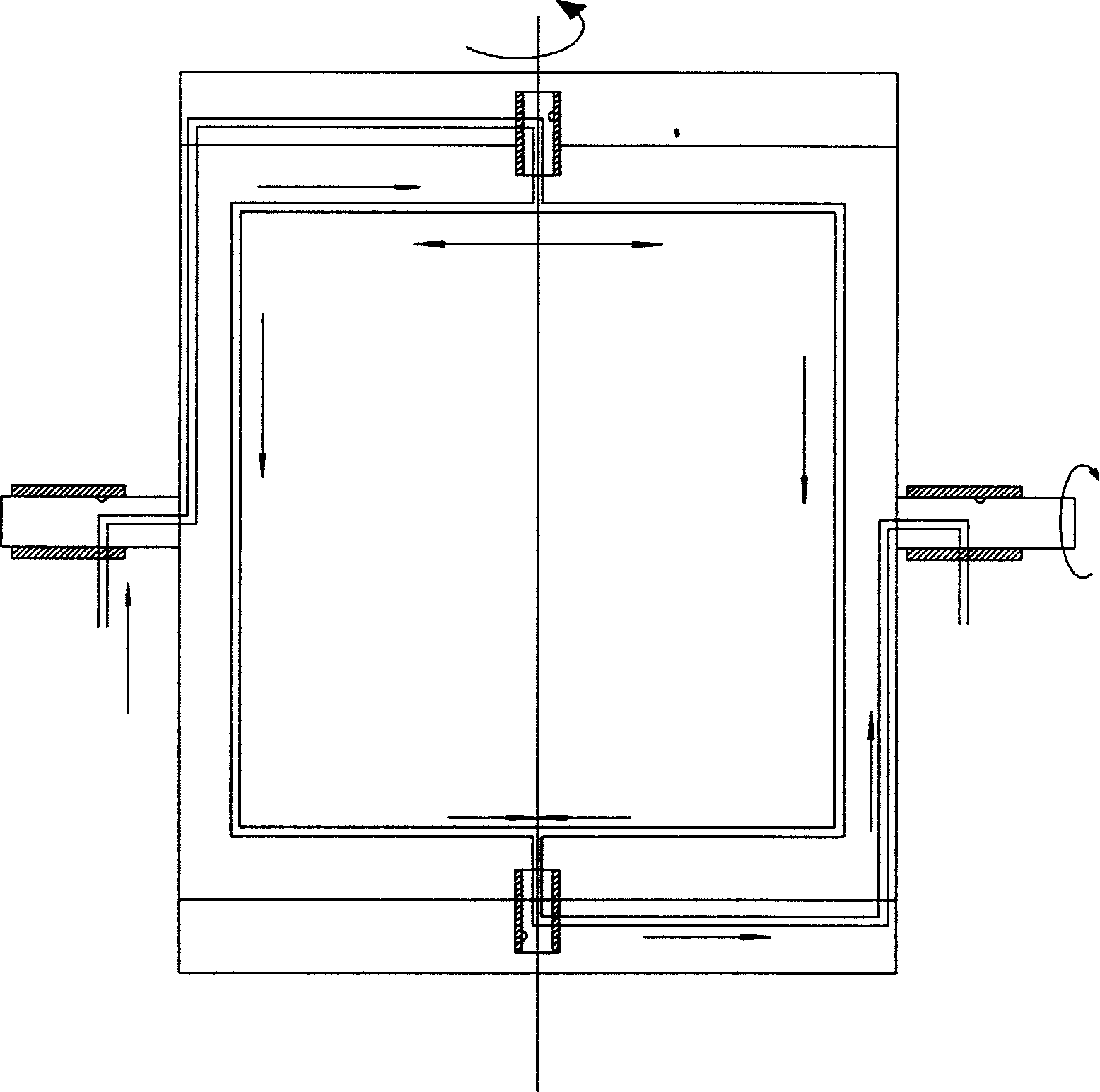

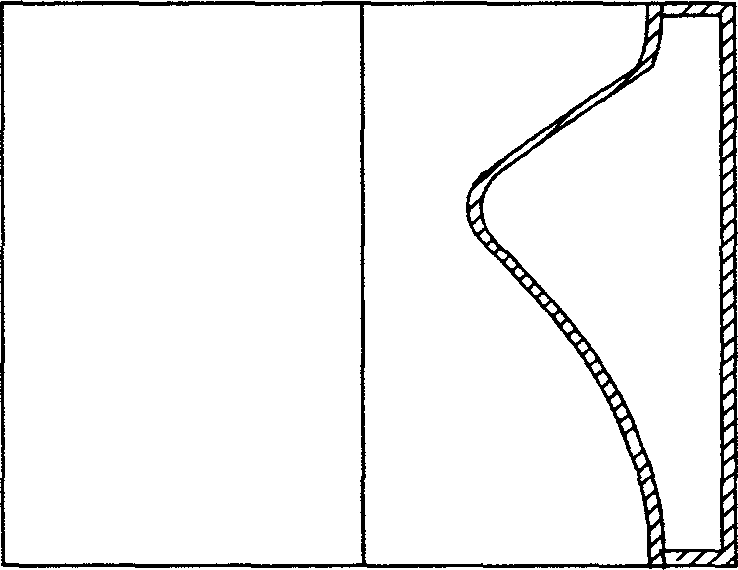

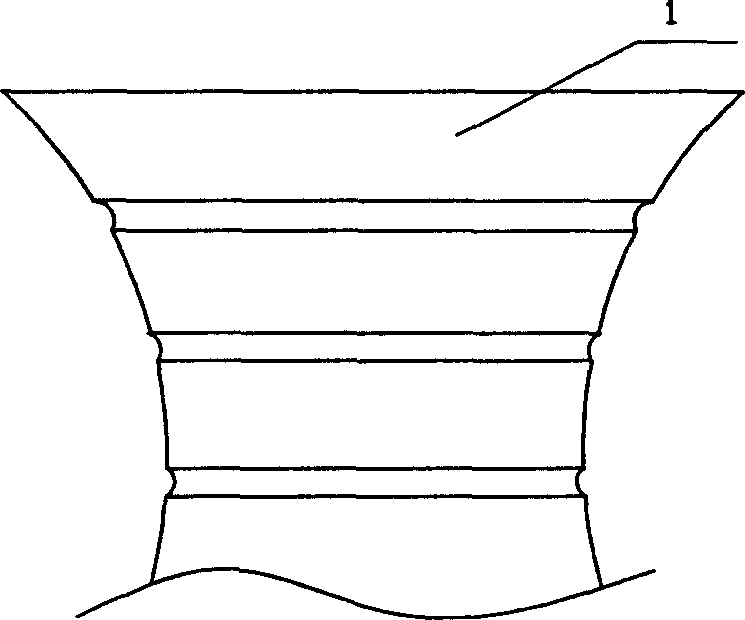

[0020] The rotomolding method of large-scale plastic products provided by the present invention is divided into two types (1) special equipment is selected, that is, the mold rotation and swing range are 360 degrees (that is, two-way rotation of 360 degrees), and electricity or oil is used as a heat source in an oven. Heating; (2) Use ordinary equipment, that is, the mold is rotated 360 degrees, and the swing range is less than 300 degrees, and the mold is heated with gas. The molding of ordinary equipment is decomposed into the following steps in sequence: (take three feedings as an example)

[0021] (1) Feeding into the mold for the first time: the feeding amount is 40%-50% of the total feeding amount;

[0022] (2) The first plasticization: the mold speed is 20-40 rpm, the swing range is 0-180 degrees, and the external heating temperature is 110-160 degrees Celsius;

[0023] (3) feeding into the mold for the second time: the feeding amount is 20%-30% of the total feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com