Closed link transportation device driven by permanent magnet linear motor

A permanent magnet linear motor and transportation device technology, applied in the field of tobacco machinery, can solve problems such as increasing maintenance workload, limiting chain length, and large chain link tension, so as to improve maintainability, simplify structure, and reduce chain link tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

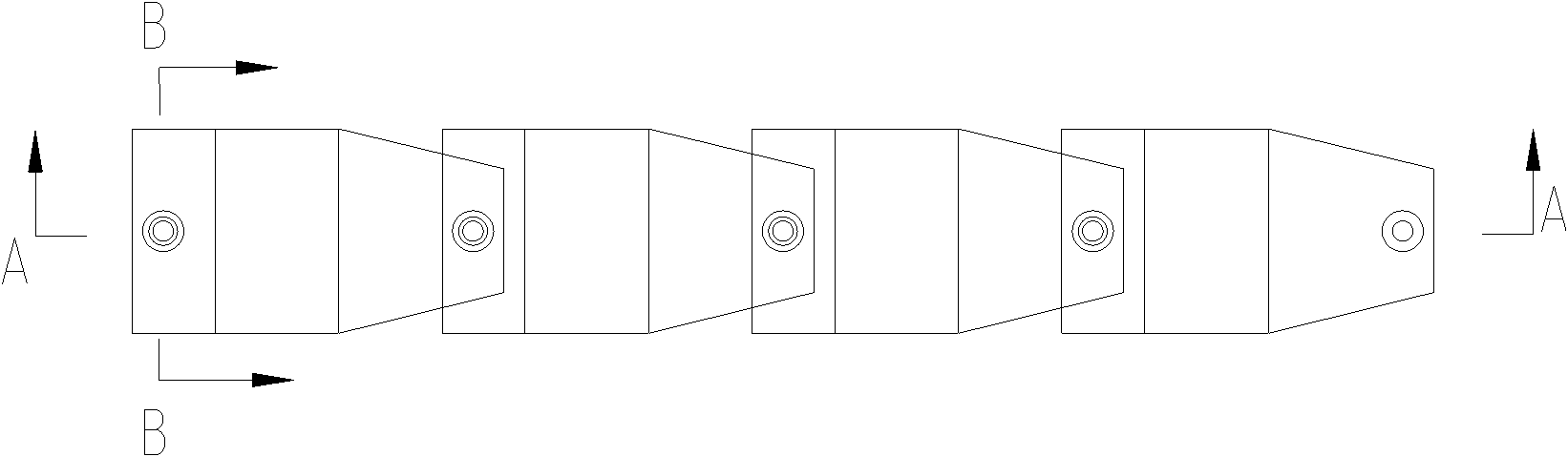

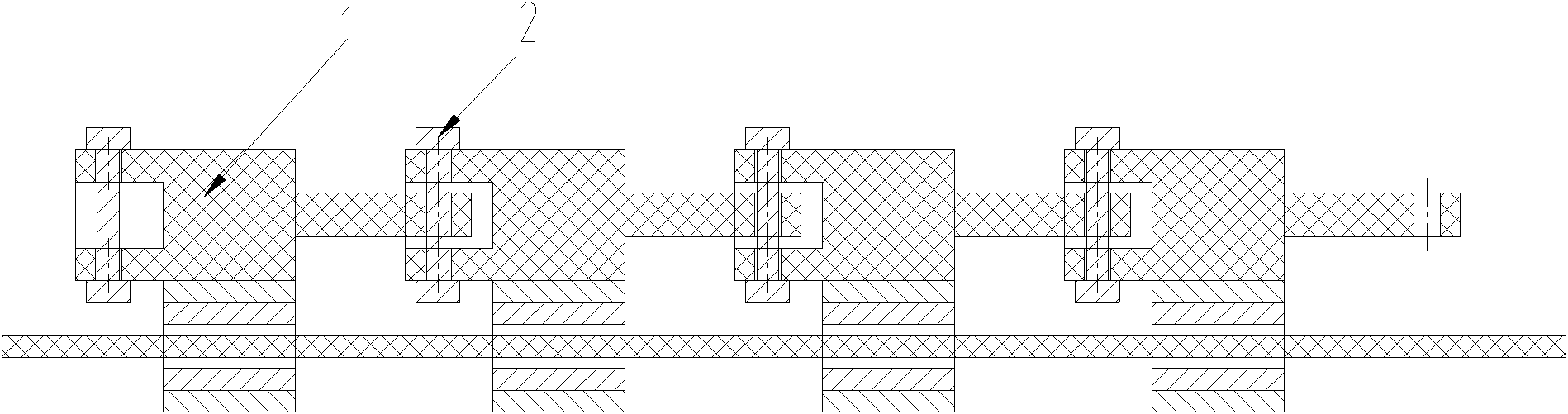

[0026] Such as Figure 1 to Figure 3 As shown, the closed link transport device driven by the permanent magnet linear motor of the present invention includes a plurality of chain links 1 ( figure 1 There are four chain links shown in ), and every two chain links 1 are connected to each other through the connecting lock 2, and the front and rear locks are locked to form a closed transportation link;

[0027] The chain links 1 of the closed transport link keep the same distance from each other; the total number of chain links 1 of a single closed link is an even number;

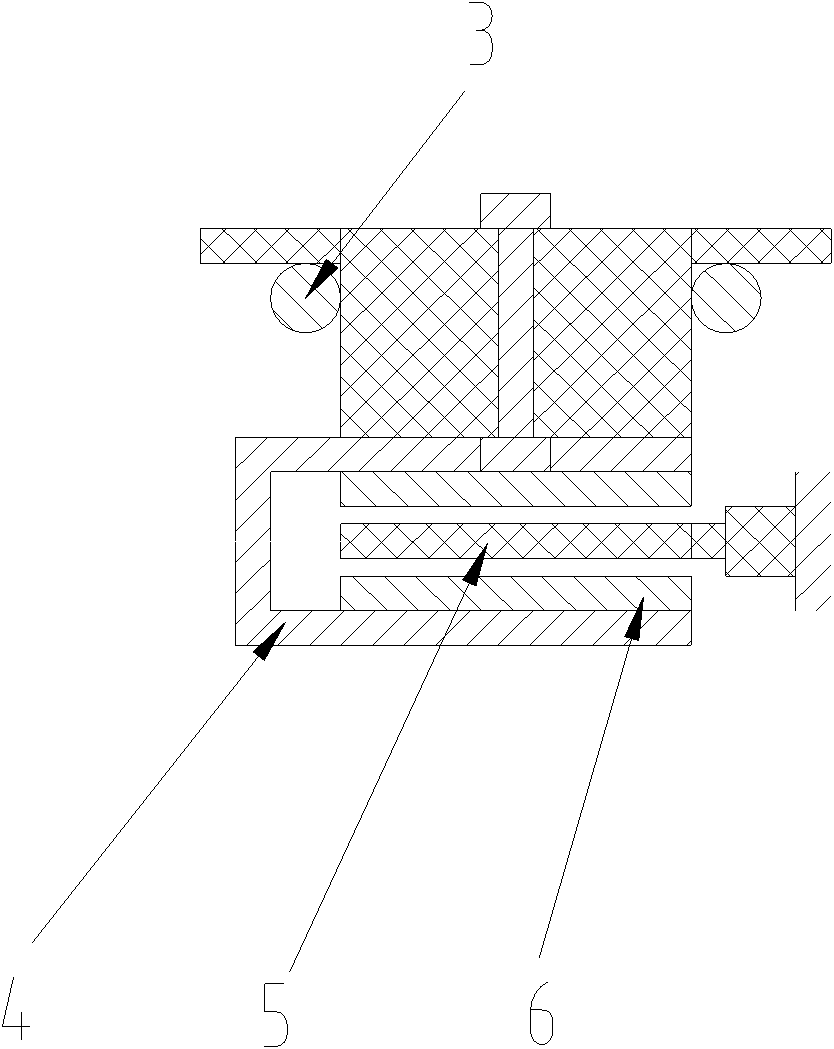

[0028] The chain link 1 is fixedly connected to the mover 4 of the linear motor, and each chain link 1 corresponds to a mover 4; or the chain link 1 is evenly distributed relative to the mover 1;

[0029] Multiple movers 4 are sleeved on the stator 5 of a linear motor; the length of the stator extends along the direction of the transport link, and the length of the stator 5 is consistent with the length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com