Labelling mechanism assemblage of bag beverage packaying machine

A packaging machine and labeling technology, used in packaging, food packaging, transportation and packaging, etc., can solve the problems of short lifespan of scissors, falling or slipping lines, and high rejection rate of packaging machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

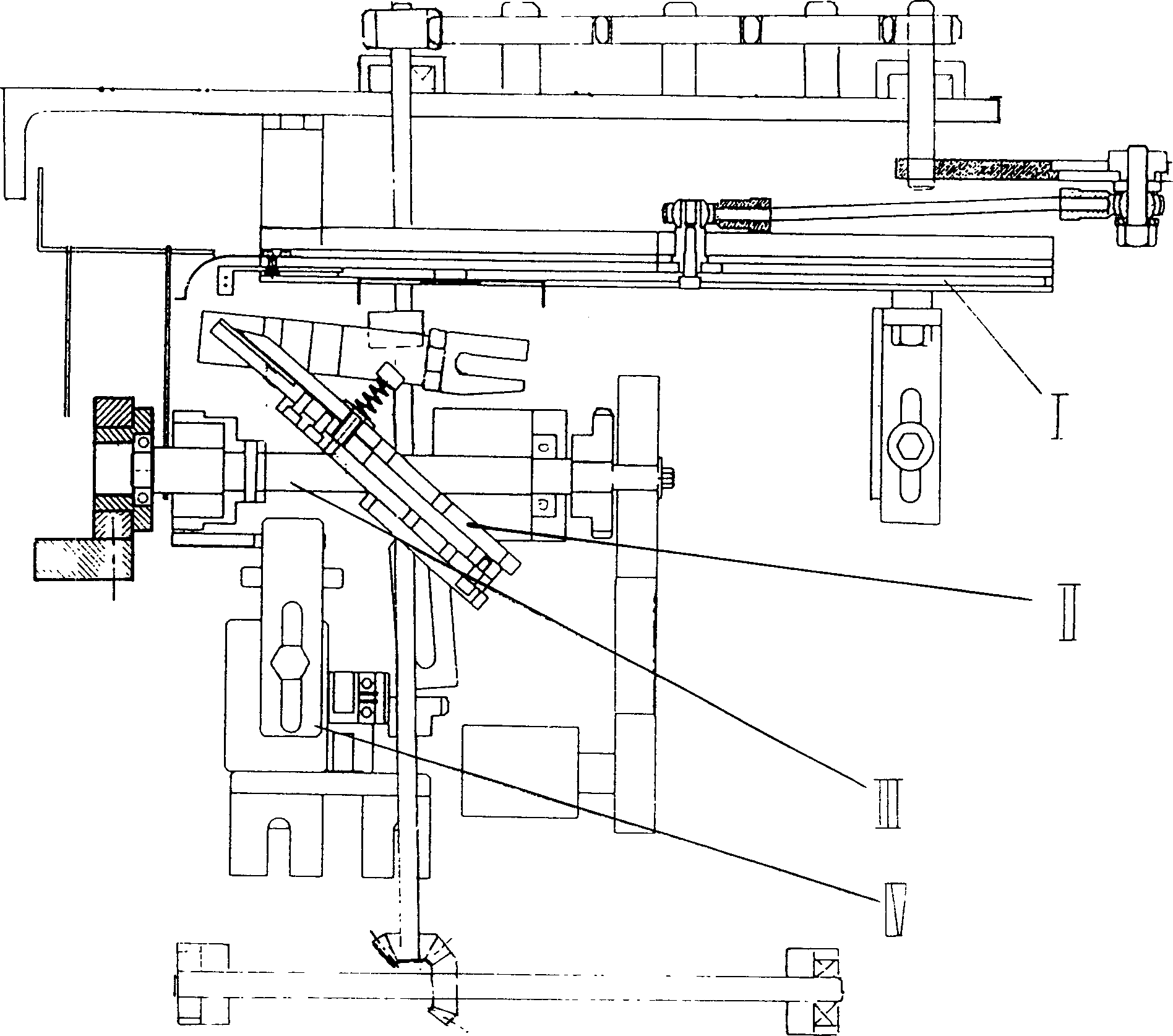

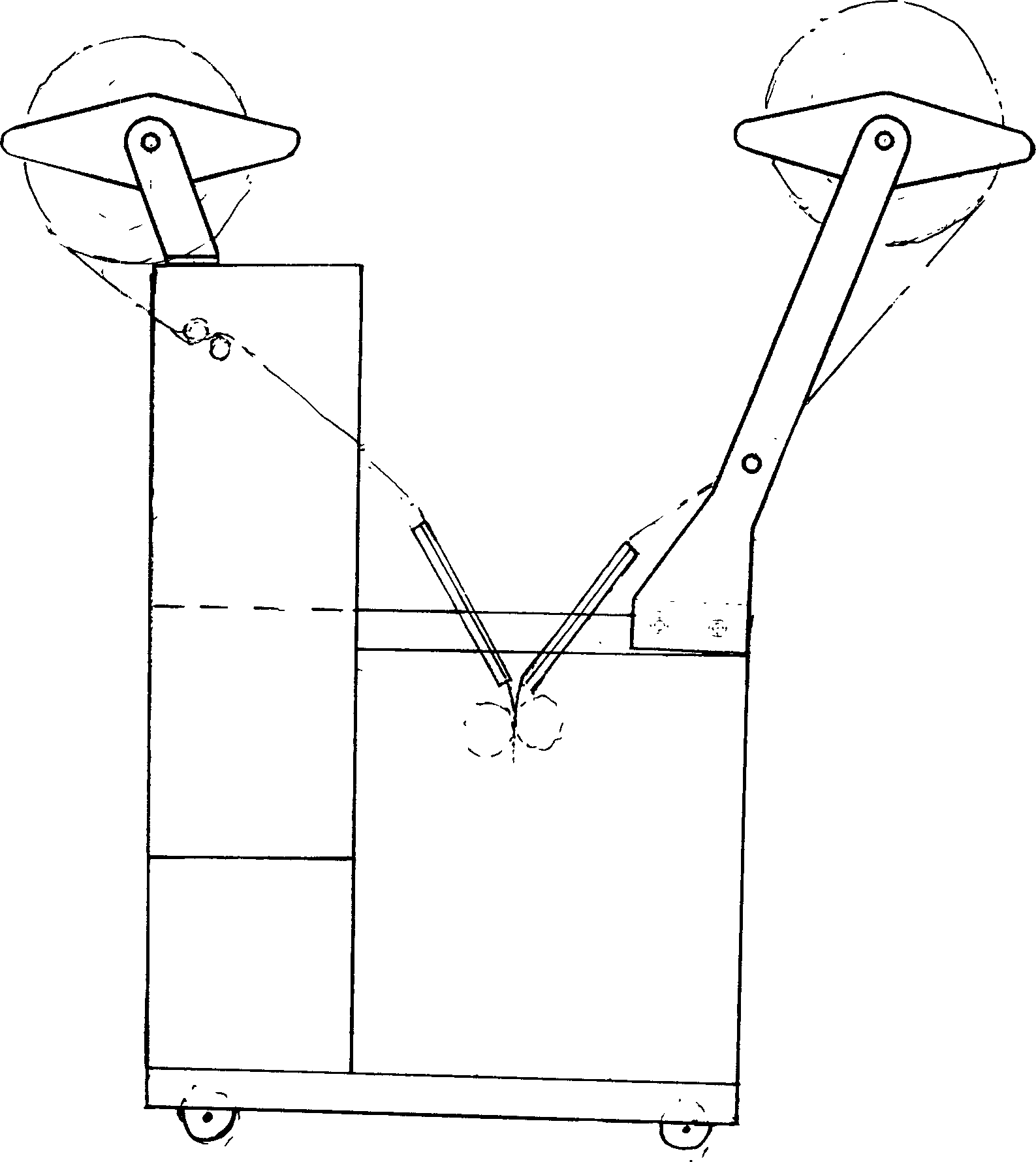

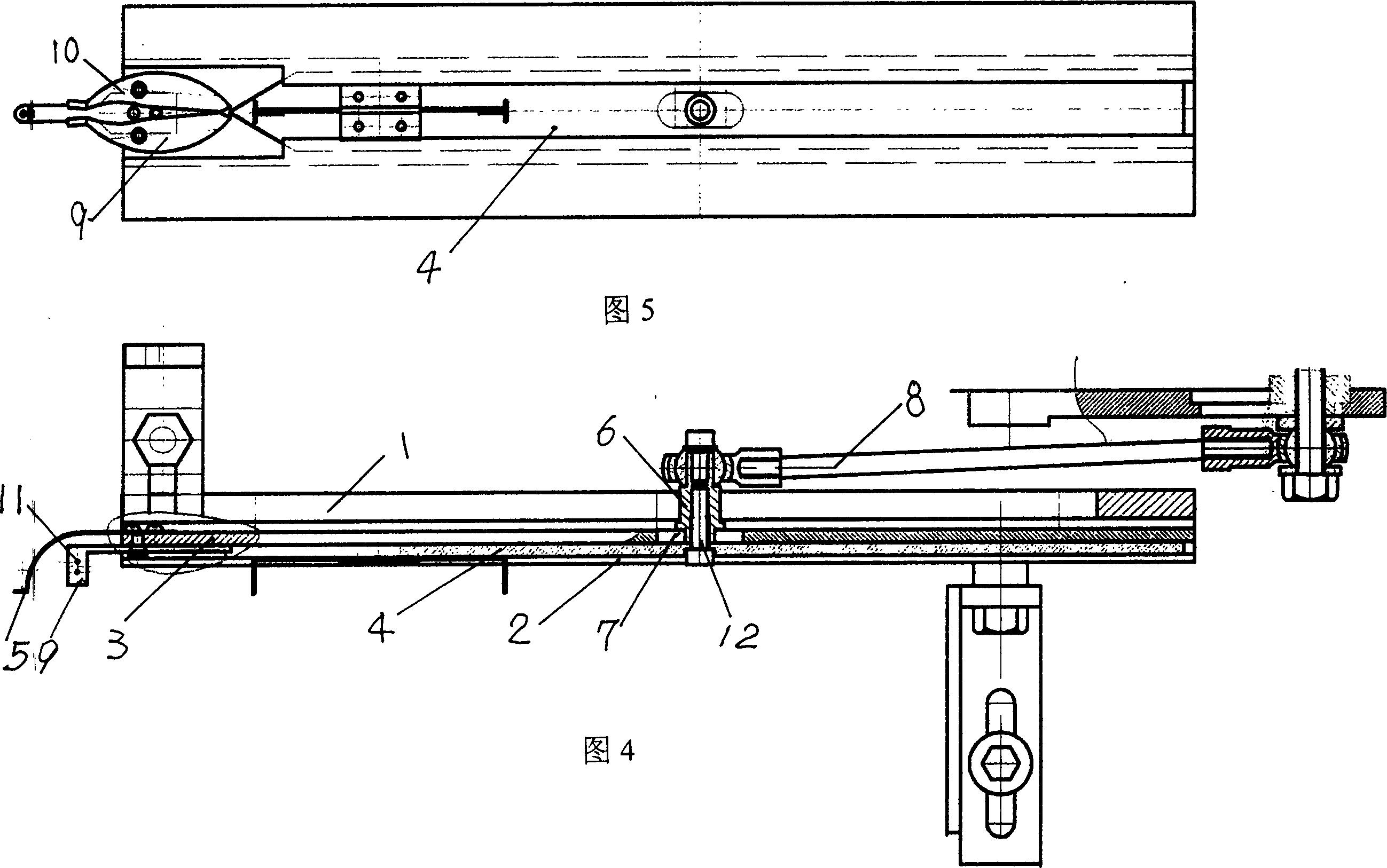

[0031] refer to Figure 1-3 , a labeling mechanism assembly of a bag beverage packaging machine, the main body, a film support, a hopper and a metering plate, is characterized in that it consists of a labeling mechanism, a wire feeding mechanism, a thread cutting mechanism, a label feeding and label cutting mechanism and a packaging The bag forming device is composed of a large label frame, a small label frame and a label slide. The frame label mechanism is placed on both sides of the top of the body, and the wire feeding mechanism, thread trimming mechanism, label feeding and label cutting mechanism are installed in the body. The other end of the eccentric connecting rod in the wire feeding mechanism is connected with the vertical shaft of the packaging machine through a multistage gear pair, and the gear transmission ratio is 1:1. not shown in the figure) connection, the vertical shaft is connected with the main shaft of the packaging machine through a bevel gear pair, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com