Environmental protection toilet flushed by circulating water and toilet sewage processing method

A sewage treatment method and circulating water technology, which is applied to the treatment and purification of toilet feces and sewage, sewage recycling devices, and the field of circulating water flushing environmental protection toilets. Bad smell residue, small footprint, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] best practice

[0022] The toilet sewage treatment method and the circulating water flushing environment-friendly toilet of the present invention will be described in detail below in conjunction with the accompanying drawings.

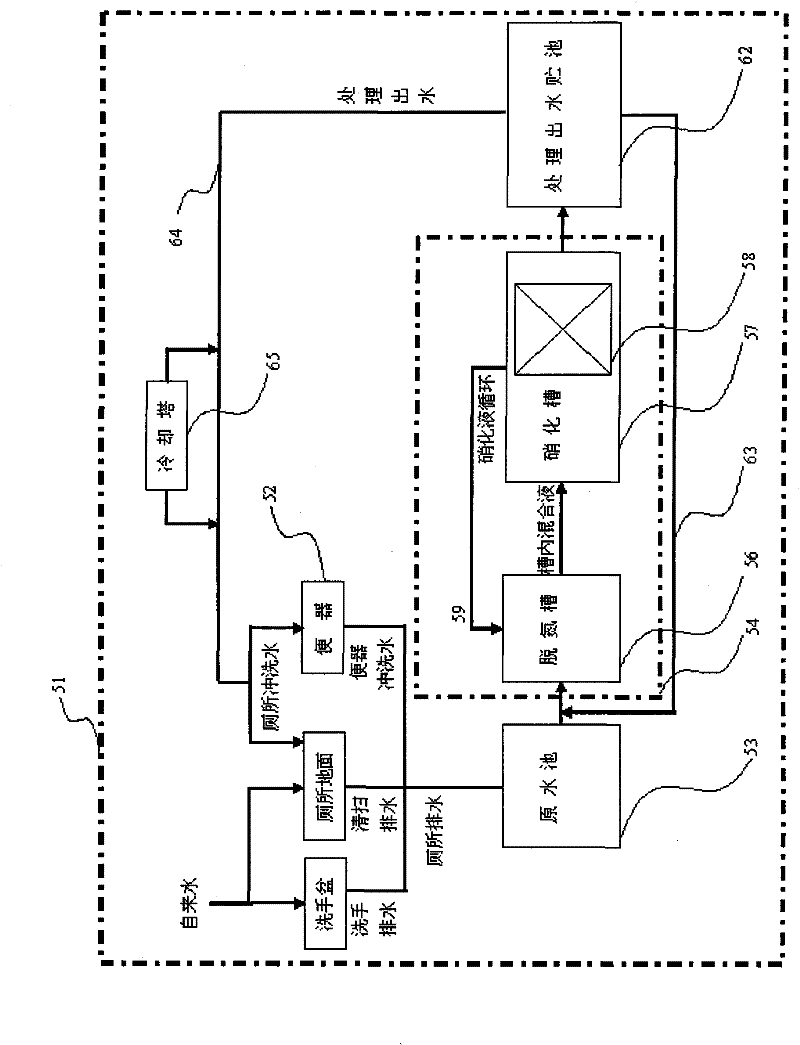

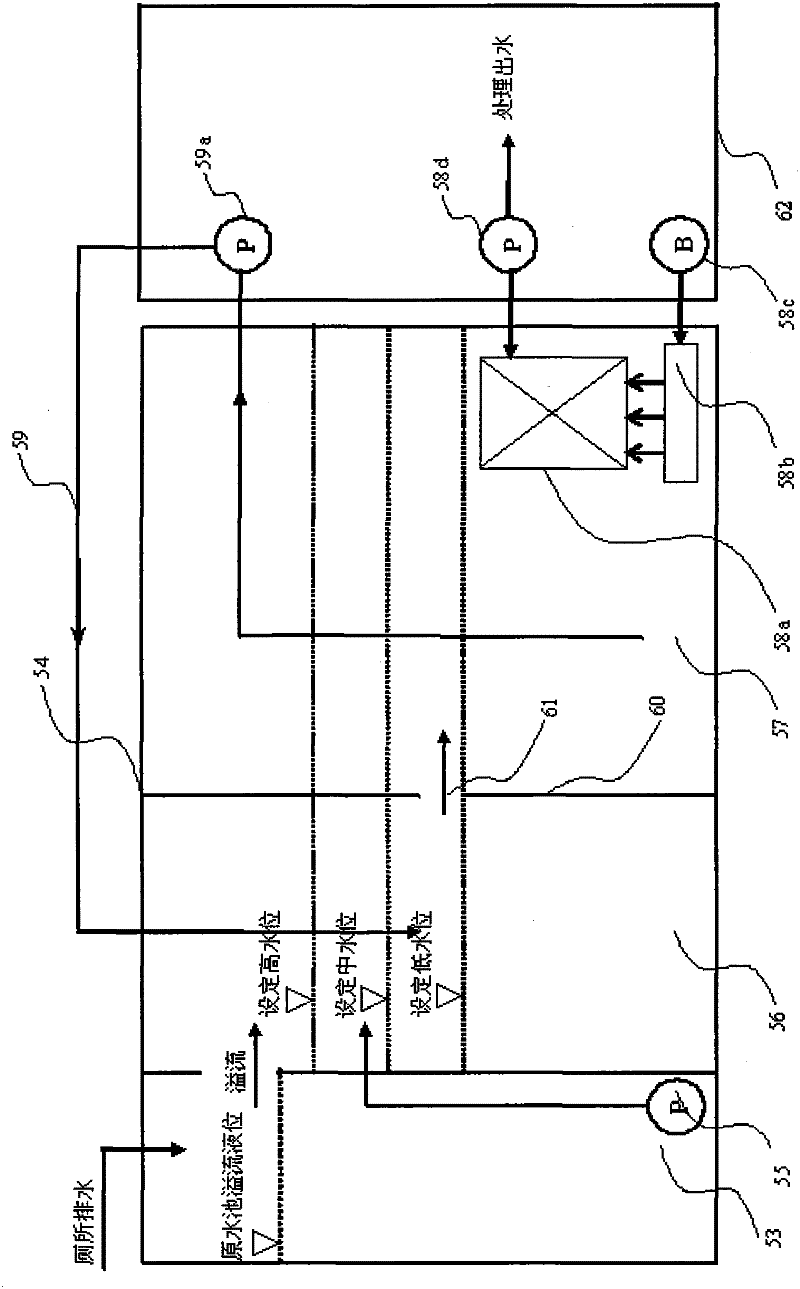

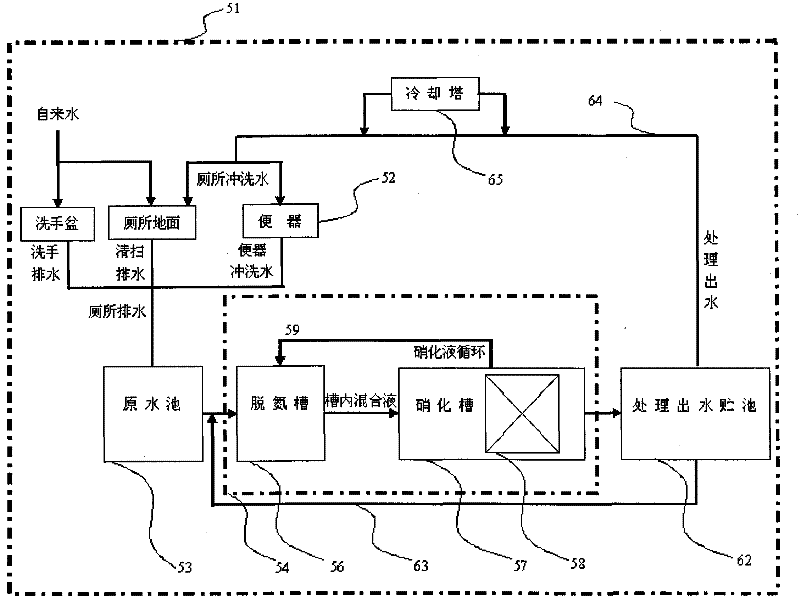

[0023] Such as figure 1 Shown: Circulating water flushes the environment-friendly toilet 51, and there is a raw water pool 53 for accumulating the toilet drainage flowing out from the toilet 52, etc. In addition to the toilet flushing water, the hand washing drainage after washing hands and the cleaning drainage used for cleaning the toilet also flow into the raw water pool 53. As the capacity of the raw water pool 53, an accumulation amount equivalent to half of the designed treatment amount of toilet drainage in one day is set.

[0024] Downstream of the raw water tank 53, a biological treatment tank 54 for biologically denitrifying the toilet drainage flowing out of the raw water tank 53 is provided. The raw water pool 53 uses a water pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com