Equal pressure structure waterproof method for die-mould steel plate tile roof

A technology of profiled steel plate and tile roof, which is applied in the direction of roof, roof and building structure using tile/slate tile. Effects of Metal Corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

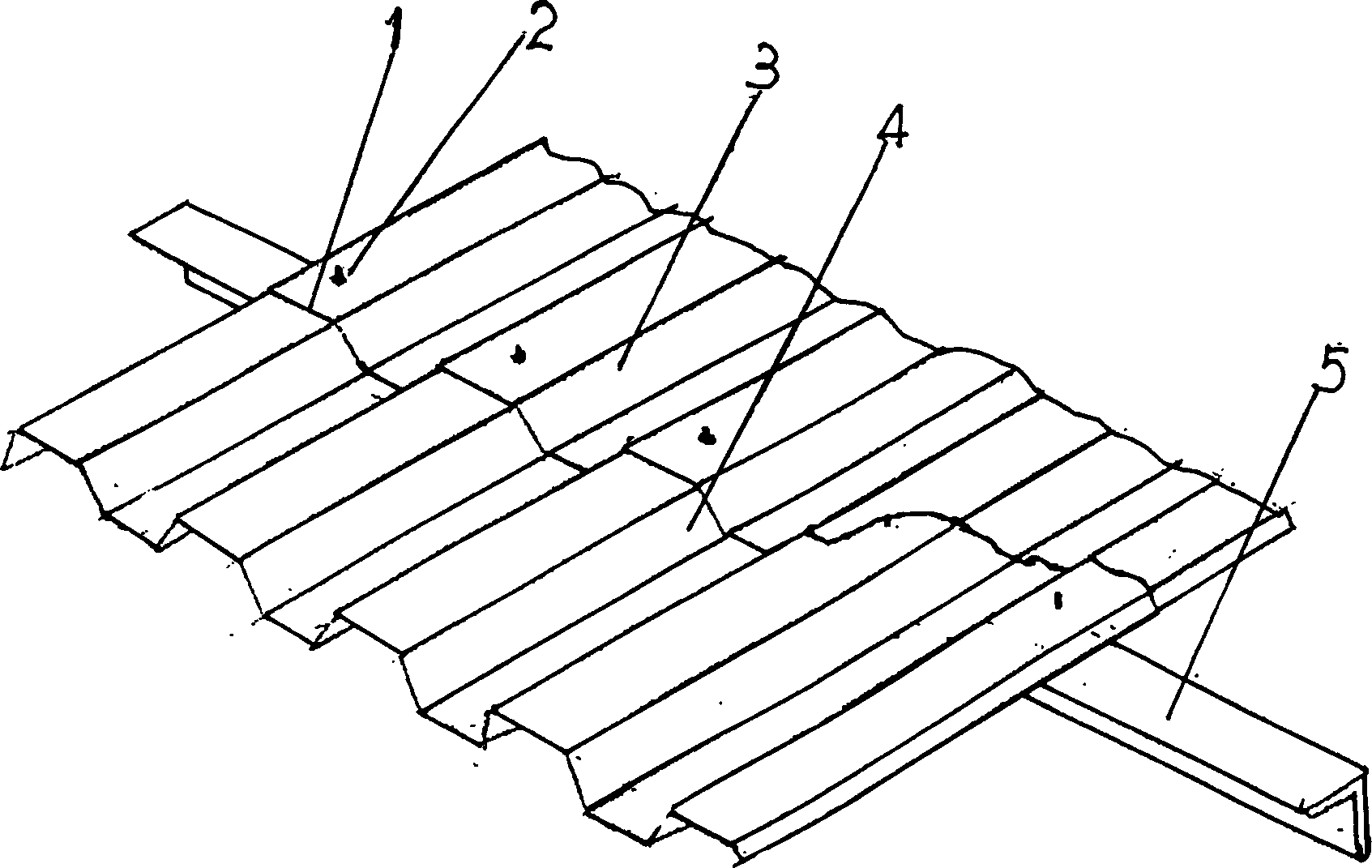

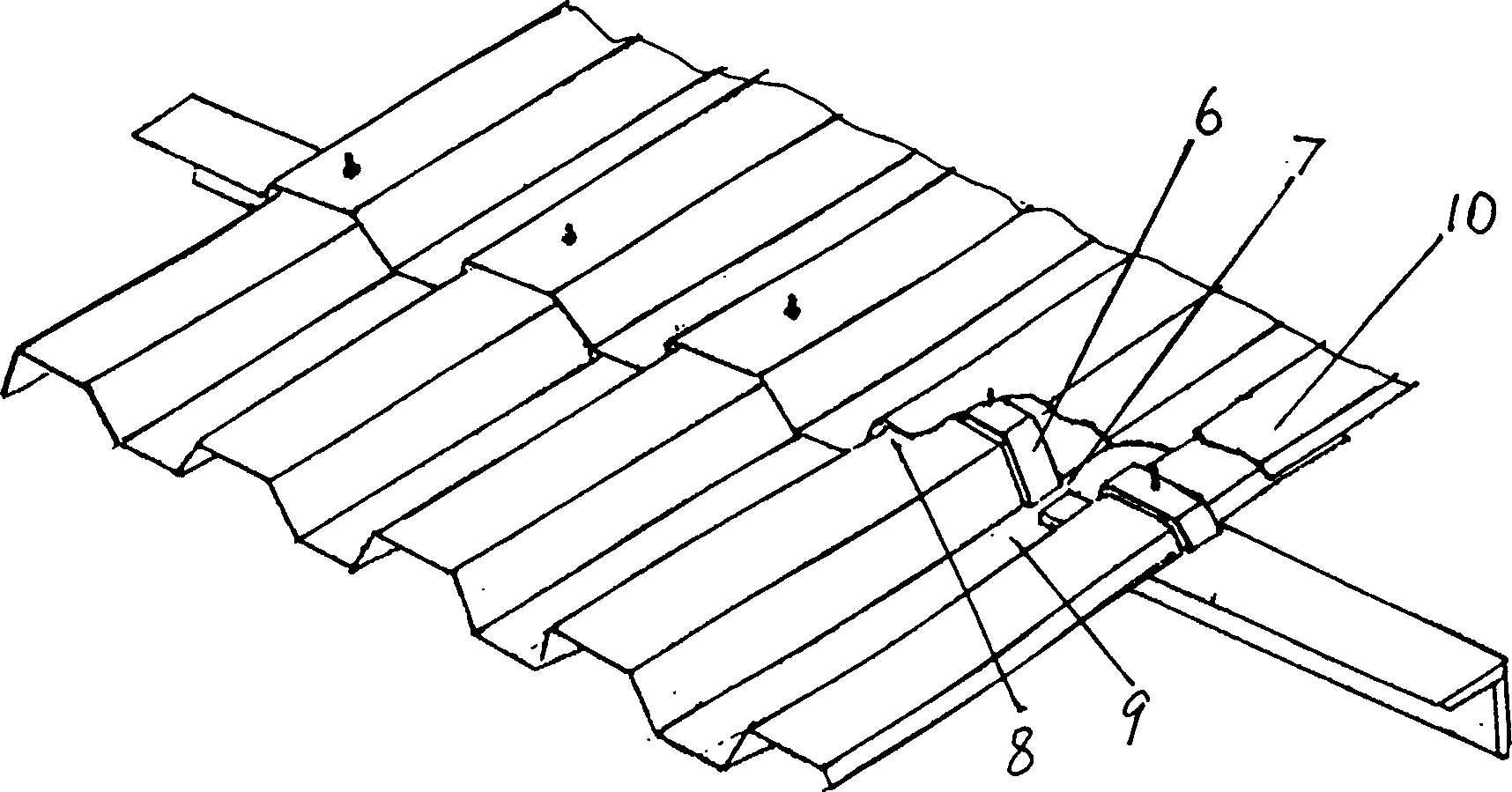

[0020] The present invention is further described in conjunction with the accompanying drawings. For example, a profiled steel tile roof with a slope of 2:100 is designed in a coastal area, and the diameter of the profiled steel tile fastener 2 is 12mm. The upper tile 3 and the profiled steel tile can be selected. The longitudinal lap joint 1 between tiles and tiles 4 has a lap length of 600m. Lay profiled steel tiles on the steel roof truss 5 from bottom to top, and clean the surface at 300mm in the middle of the longitudinal lap. After meeting the bonding requirements, A rubber strip with a width of 40mm and a thickness of 5mm is used as the equal pressure sealing strip 6, which is pasted on the surface of the lower tile 4, and the equal pressure sealing strip 6 is cut at a distance of 10mm at the tile groove 9 to form a drainage groove 7, and then the upper tile is laid 3. Lap according to the length of 600mm, center the isobaric sealing strip, fix the lower tile 4 and upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com