Tranformer cooling device and manufacturing method for microwave oven

A cooling device and transformer technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of inability to produce cooling effect, poor heat dissipation effect, etc., and achieve the effect of firm device, simple process, and enlarged contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The features and technical content of the present invention will be further described in detail below in conjunction with preferred embodiments and specific implementation methods.

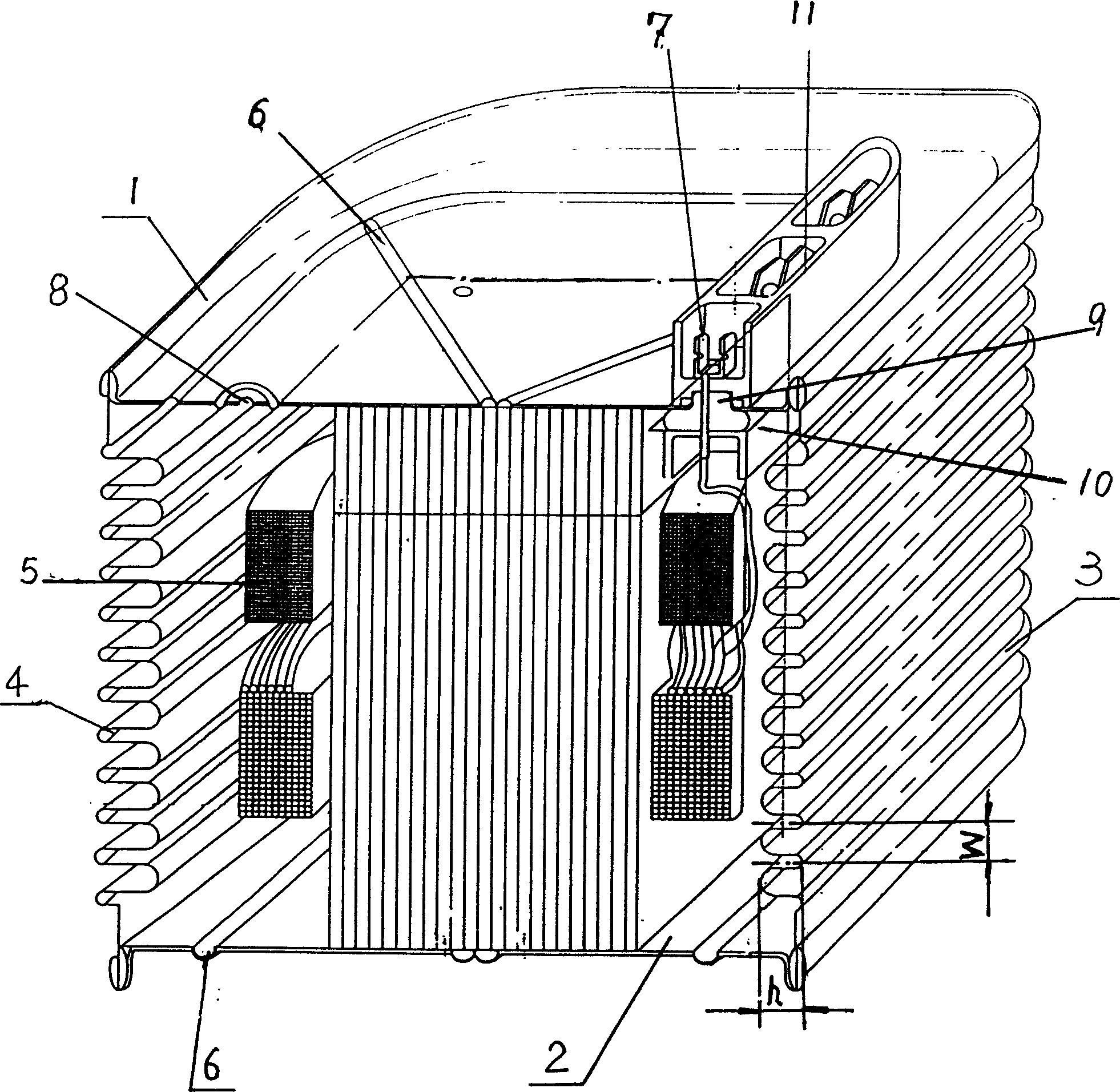

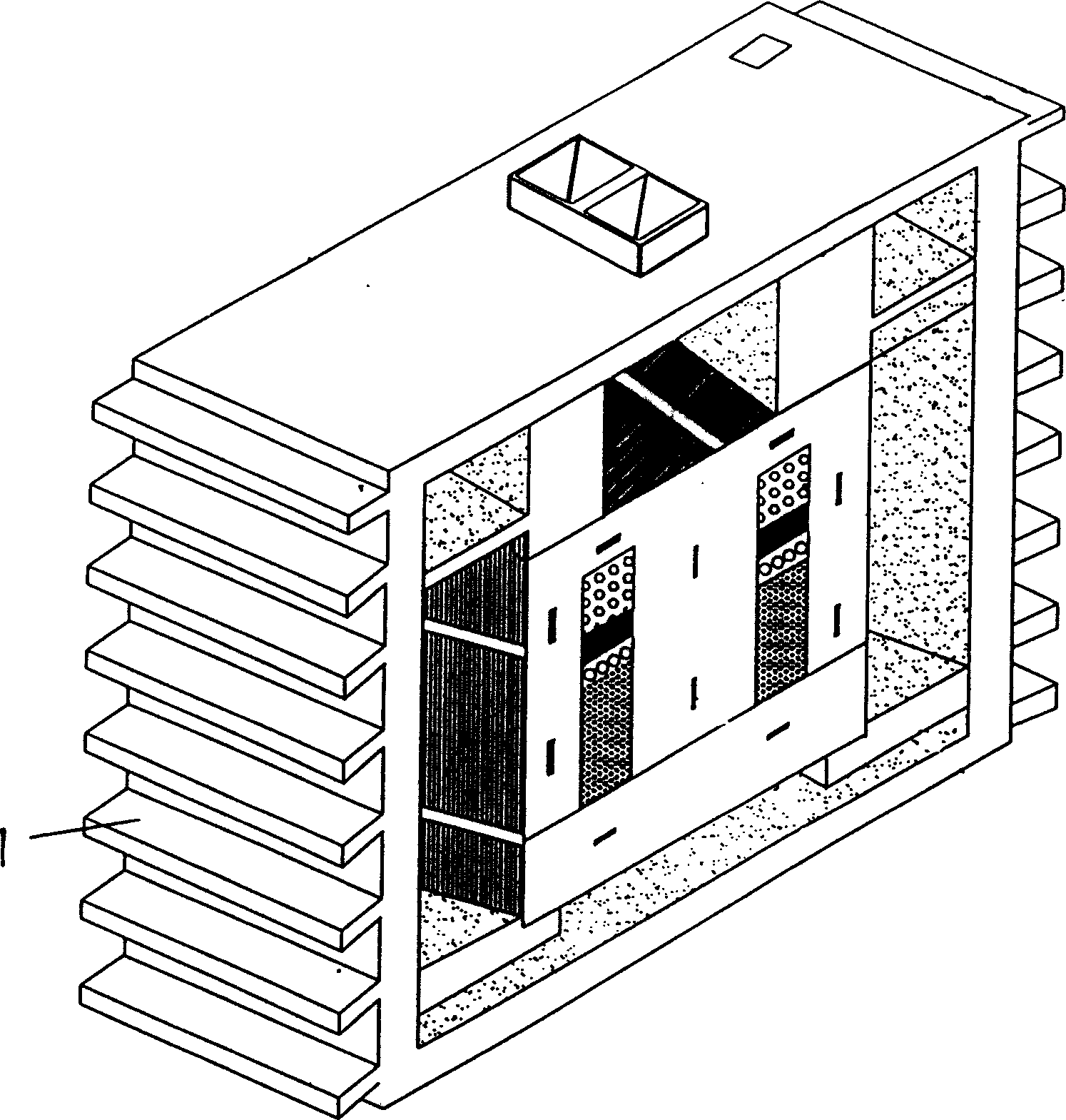

[0020] Please refer to figure 1 , a transformer cooling device for a microwave oven and a manufacturing method, mainly contain a container, cooling oil placed in the container and a transformer, the container is composed of an upper plate 1, a lower plate 2 and a container body 3, the cross-section of the container body wall It is corrugated 4, and the upper plate 1 and the lower plate 2 are fixedly connected to the upper and lower ports of the container body respectively to form a closed container with four corners in an arc shape. The container can also be round or other polygonal. The upper plate 1 and the lower plate 2 Rib 6 is provided. The upper surface of the upper plate 1 is provided with a connecting terminal 7 and an oil filling port 8. The transformer 5 is placed in the contain...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap