Fastener strip with magnetic body, and method and device for manufacturing the fastener strip

A technology of zipper tapes and magnets, applied in the directions of transportation and packaging, chemical instruments and methods, special positions of vehicles, etc., can solve complex and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0121] Based on typical embodiments, embodiments of the present invention will be described in further detail below with reference to the drawings.

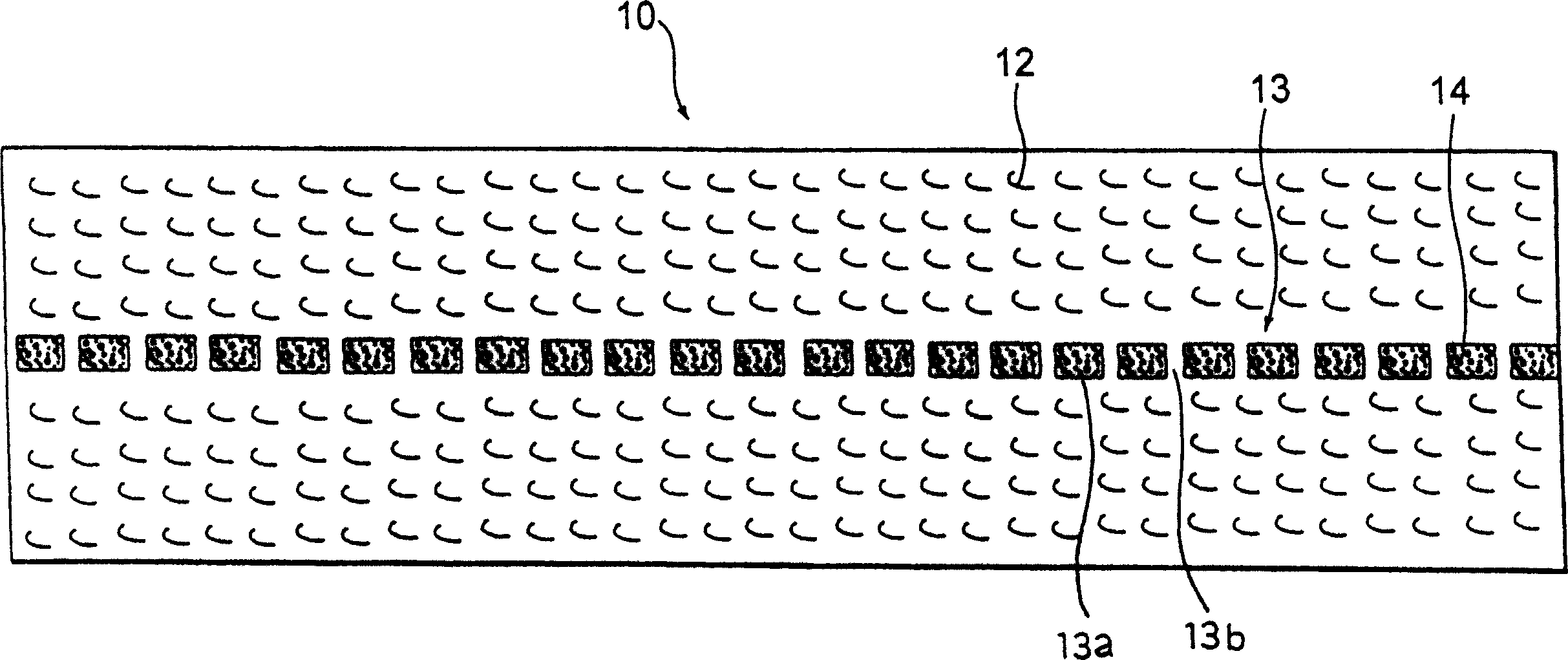

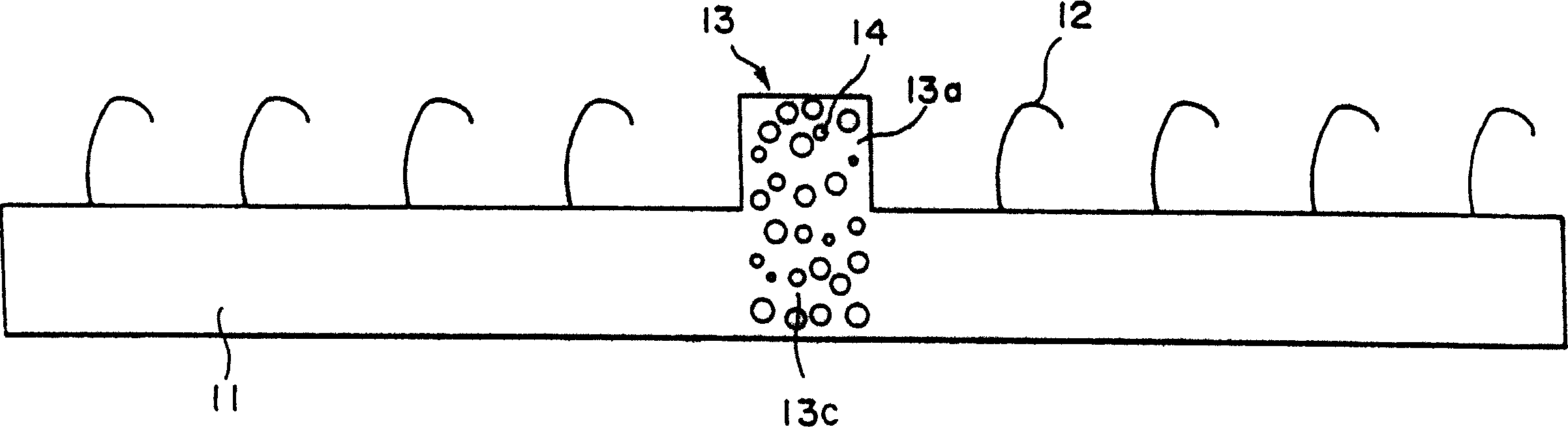

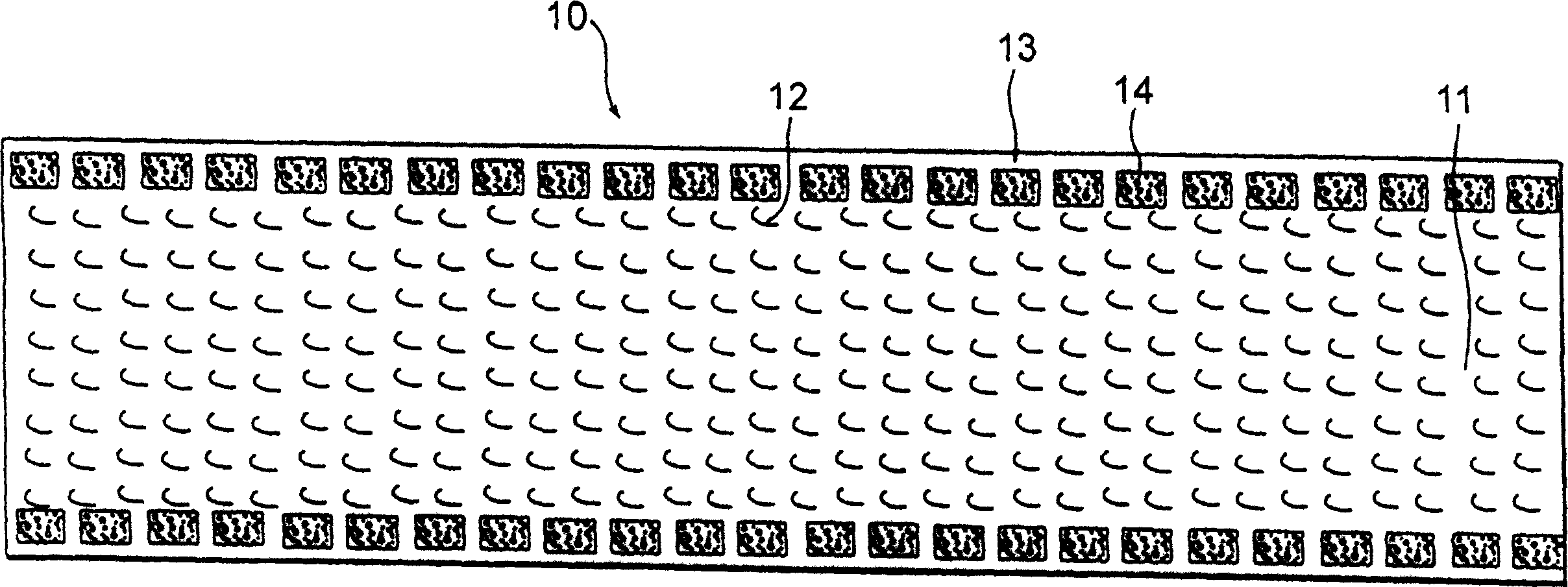

[0122] figure 1 with 2 A top view and a sheared end of a main embodiment of the invention are schematically illustrated, respectively. The zipper tape 10 has a flat substrate 11 and engaging elements 12 consisting of a plurality of hook elements protruding from the engaging surface of the substrate 11, and the zipper tape 10 also includes a row of magnets 13 protruding from the surface of the substrate 11 , and roughly arranged below the centerline of the zipper tape 10 . The magnet 13 is composed of many magnetic protruding portions 13a made of a synthetic resin material in which magnetic particles 14 are mixed, and located in the raw material portion 13c of the substrate 11 below these protruding portions 13a. The particles 14 are mixed, and the magnetic particles 14 are not dispersed throughout the substrate 11 . Therefor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com