Auxiliary suction inlet of vacuum sweeper

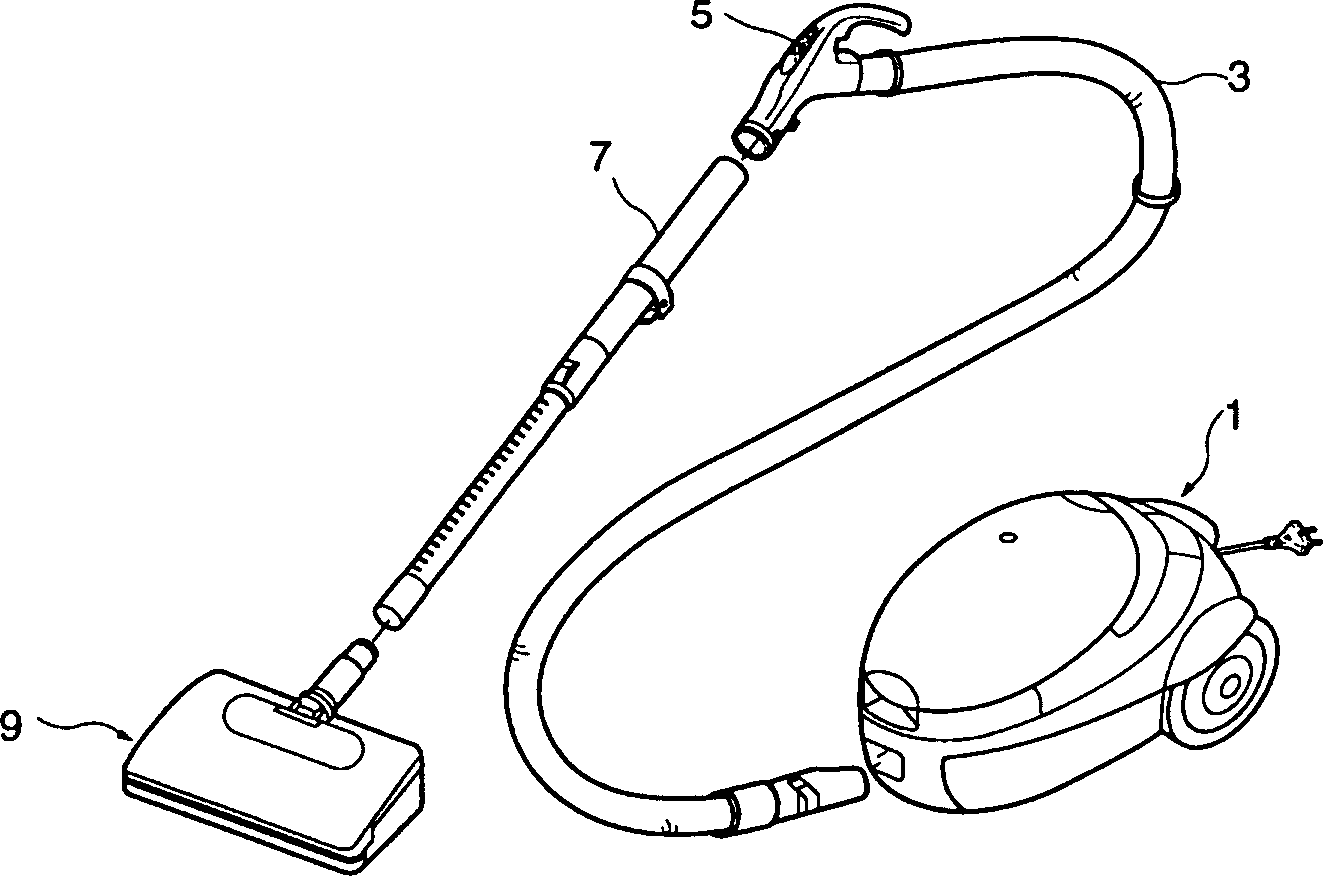

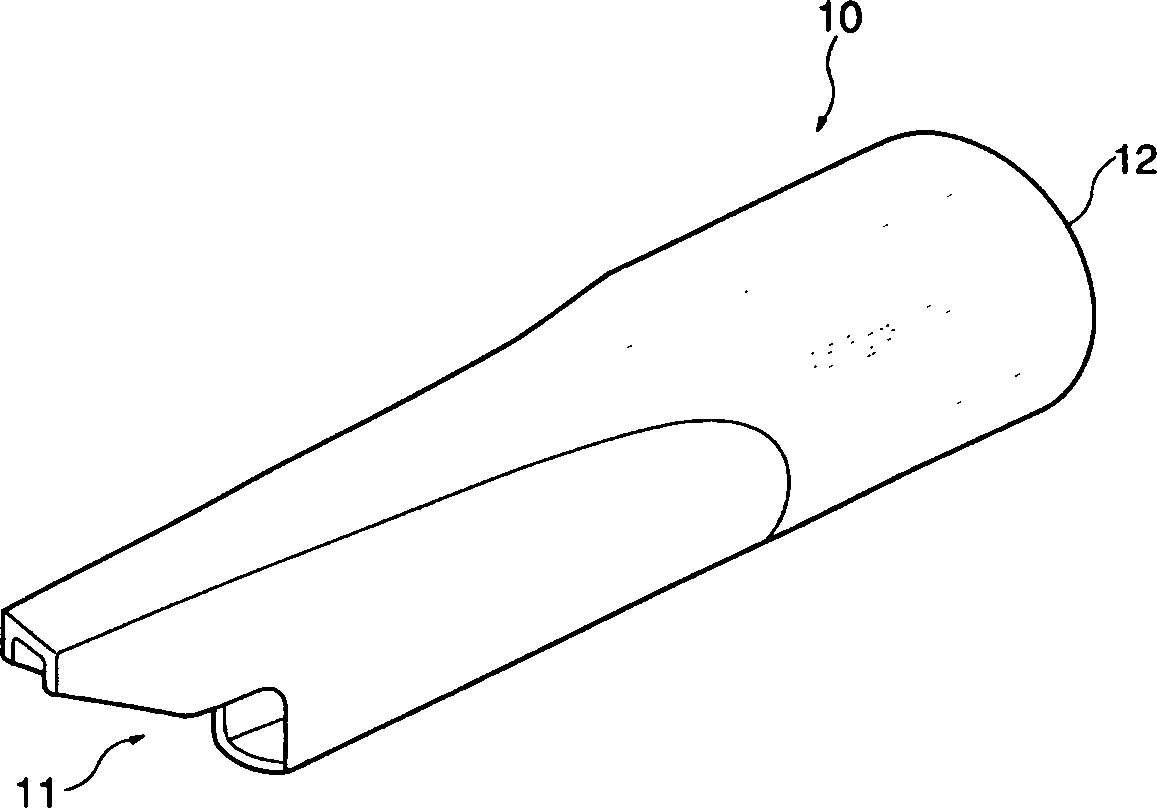

A vacuum cleaner and suction port technology, applied in the directions of vacuum cleaners, suction nozzles, handles, etc., can solve the problems of easy loss, complicated operation, small size of the auxiliary suction port 10, etc., and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

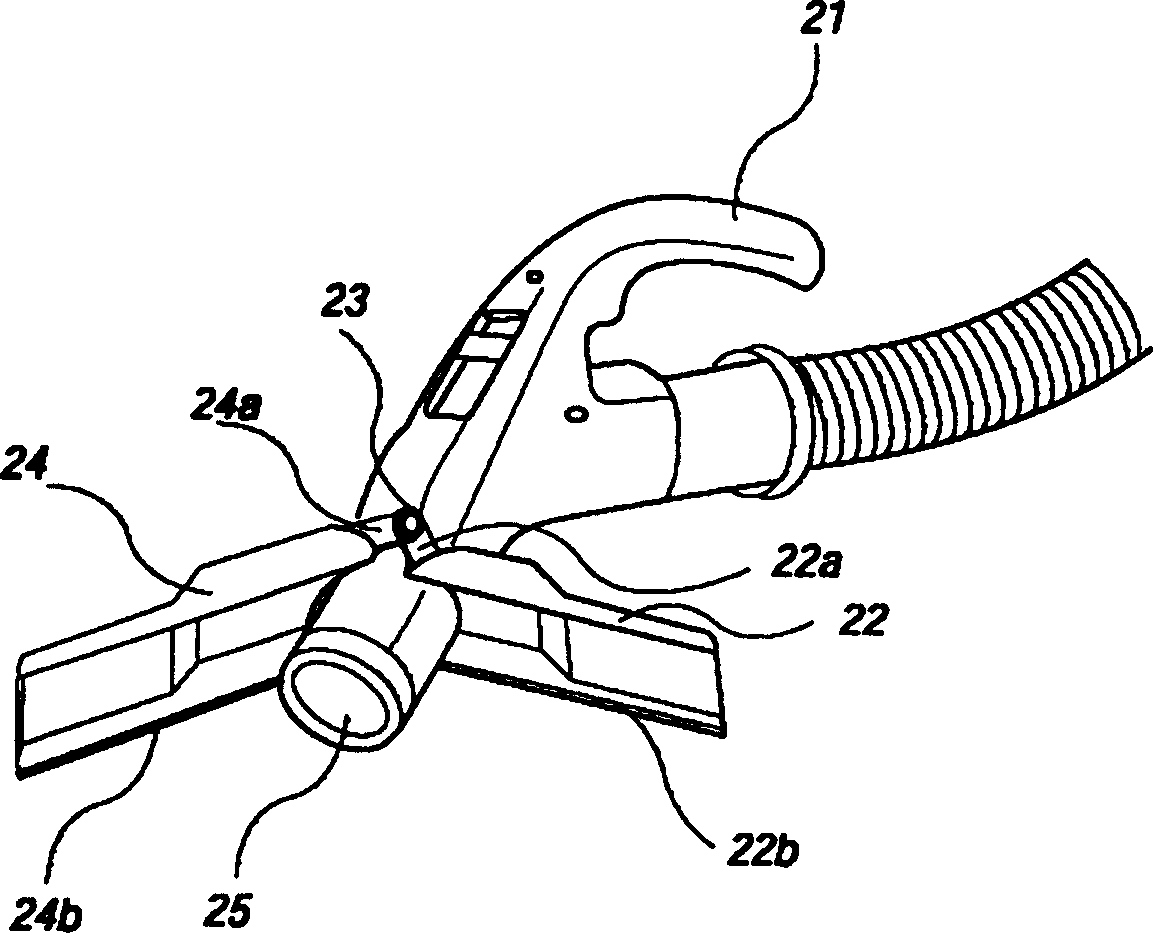

[0017] image 3 Shown is a schematic diagram of the three-dimensional structure of the auxiliary suction port of the embodiment of the present invention, Figure 4 yes image 3 Schematic diagram of the use status of the auxiliary suction port shown. As shown in the figure, a pair of blades 22 and 24 of the auxiliary suction port 20 of the present invention are assembled with the rotating shaft 23 at the front end of the handle portion 21, so that the inflow port 27 at the opening communicates with the suction port 25 of the handle portion; the auxiliary suction port 20 includes: a first blade 22 and a second blade 24 assembled symmetrically on the basis of the rotating shaft 23, the rear sides of the first blade 22 and the second blade 24 are respectively extended with connecting hinge pieces 22a and 24a, and the inner wall of the first blade 22 The upper and lower side edges are provided with hanging grooves 22b, and the outer walls of the upper and lower side edges of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com