Vacuum cleaner electric wire bobbin disk assembly

A technology for vacuum cleaners and wire coils, which is applied to electrical components, cable arrangement between relatively moving parts, cable installation, etc. Isokinetic motion and other issues to achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

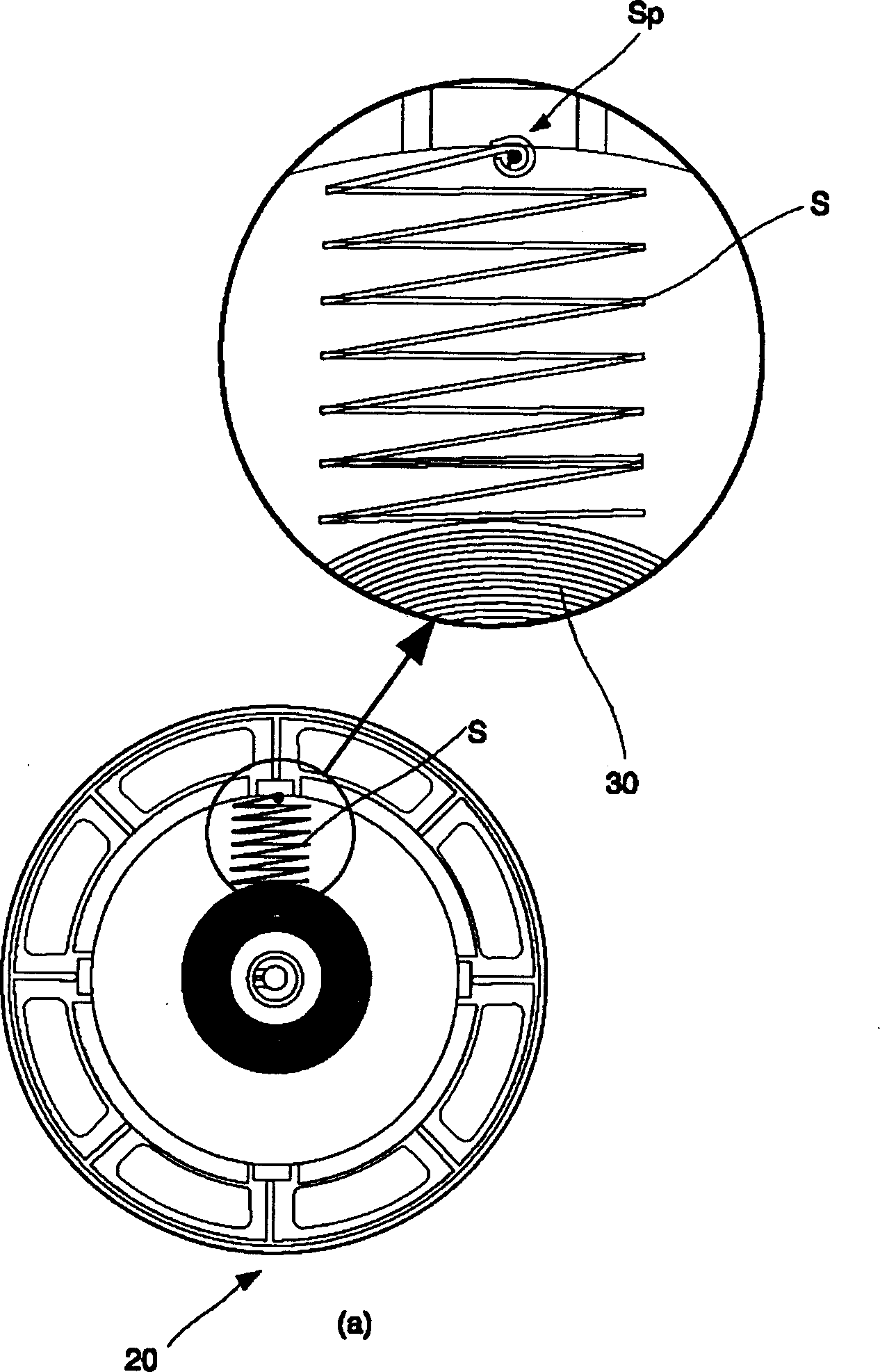

[0024] Figure 4 The structure of the reel 20 in the electric wire reel assembly of the present invention is shown. As shown, a spring 30 is provided inside the reel 20 . The reel 20 rotates around the support shaft H to unwind or wind the electric wires on the electric wire reel.

[0025] In addition, the spring 30 provided inside the above-mentioned reel 20 generates an elastic restoring force for winding the reel 20 . Its one side is connected on the rotatable reel 20, and the other side is connected on the fixed frame.

[0026] The spring 30 is provided inside the reel 20 , actually between the inner surface of the cylindrical winding member 24 around which the electric wire is wound and the inner diameter 26 of the support shaft H inserted.

[0027] In addition, according to the present invention, a coil spring S is provided on the outer side of the spring 30 . The outer portion of the spring is fixed by the fixing member Sp on the inner surface 22 of the winding memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com