Film-forming apparatus

A film-forming device and film-forming chamber technology, applied in gaseous chemical plating, coating, electrical components, etc., can solve the problems of increased work load, limited work space, difficult maintenance work, etc., to ensure work space and reduce The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

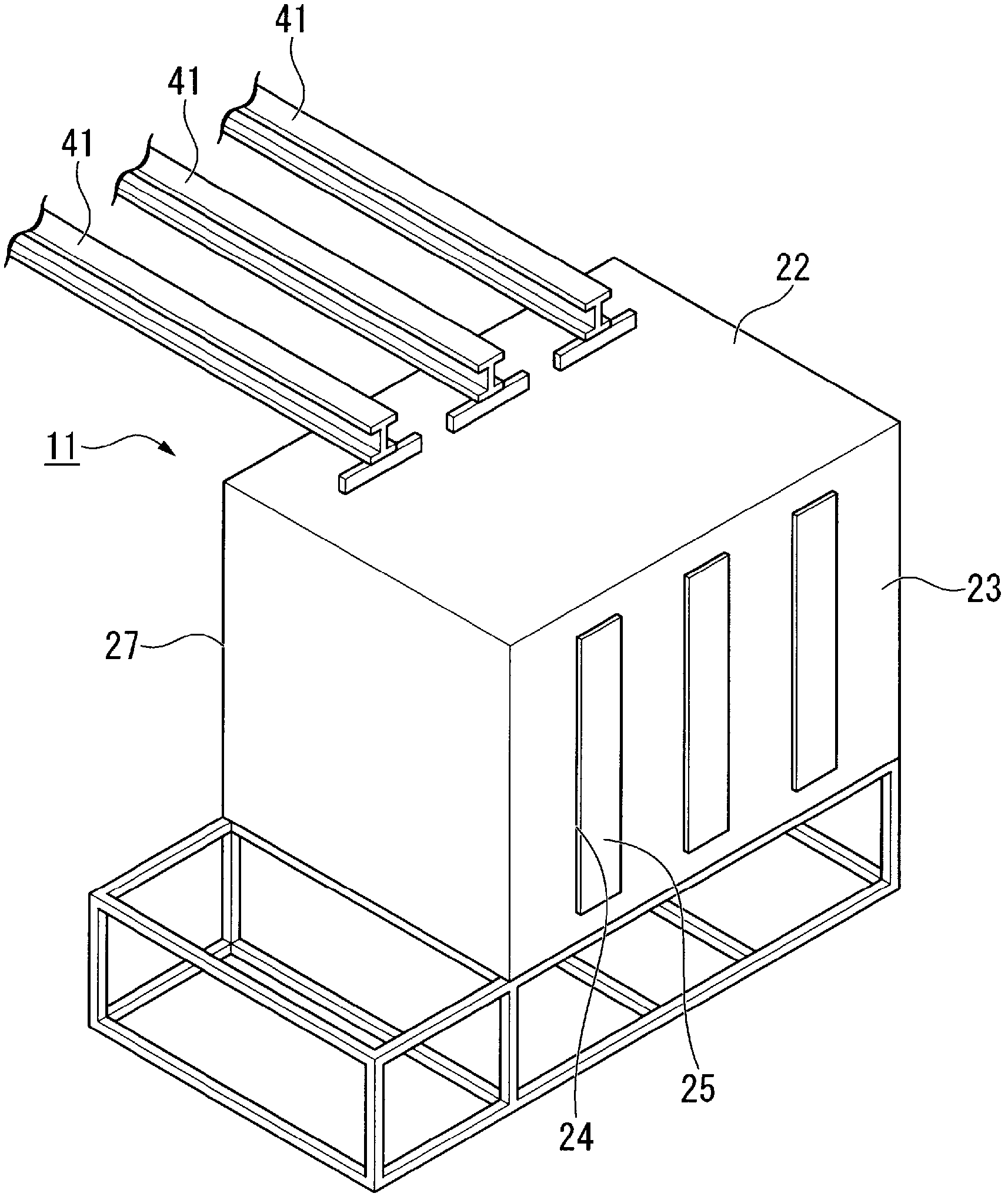

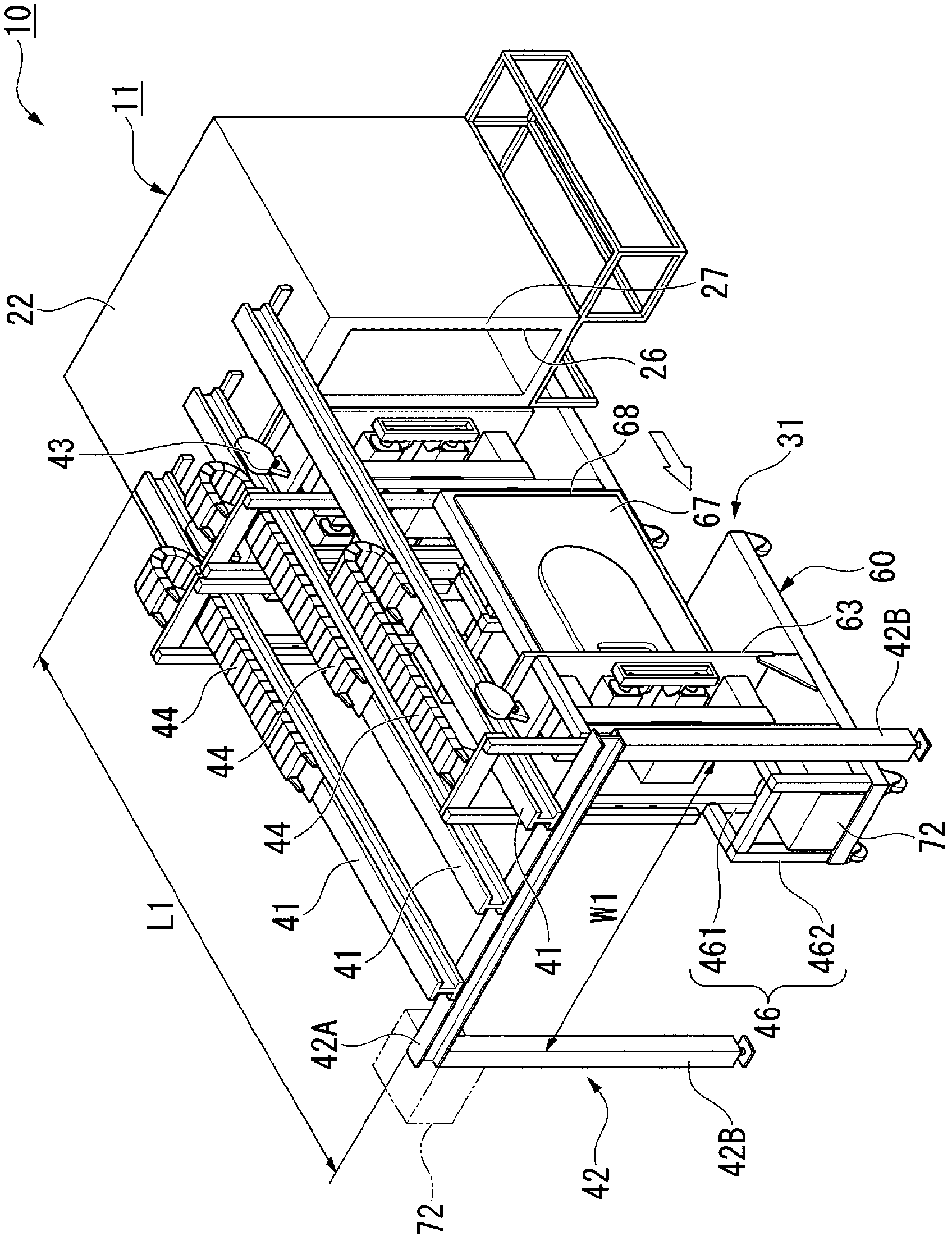

[0034] Next, embodiments of the film formation apparatus according to the present invention will be described with reference to the drawings.

[0035] In addition, in each drawing used in the following description, in order to make each constituent element a size that can be recognized on the drawing, the dimensions and ratios of each constituent element are suitably different from actual ones.

[0036] (film forming device)

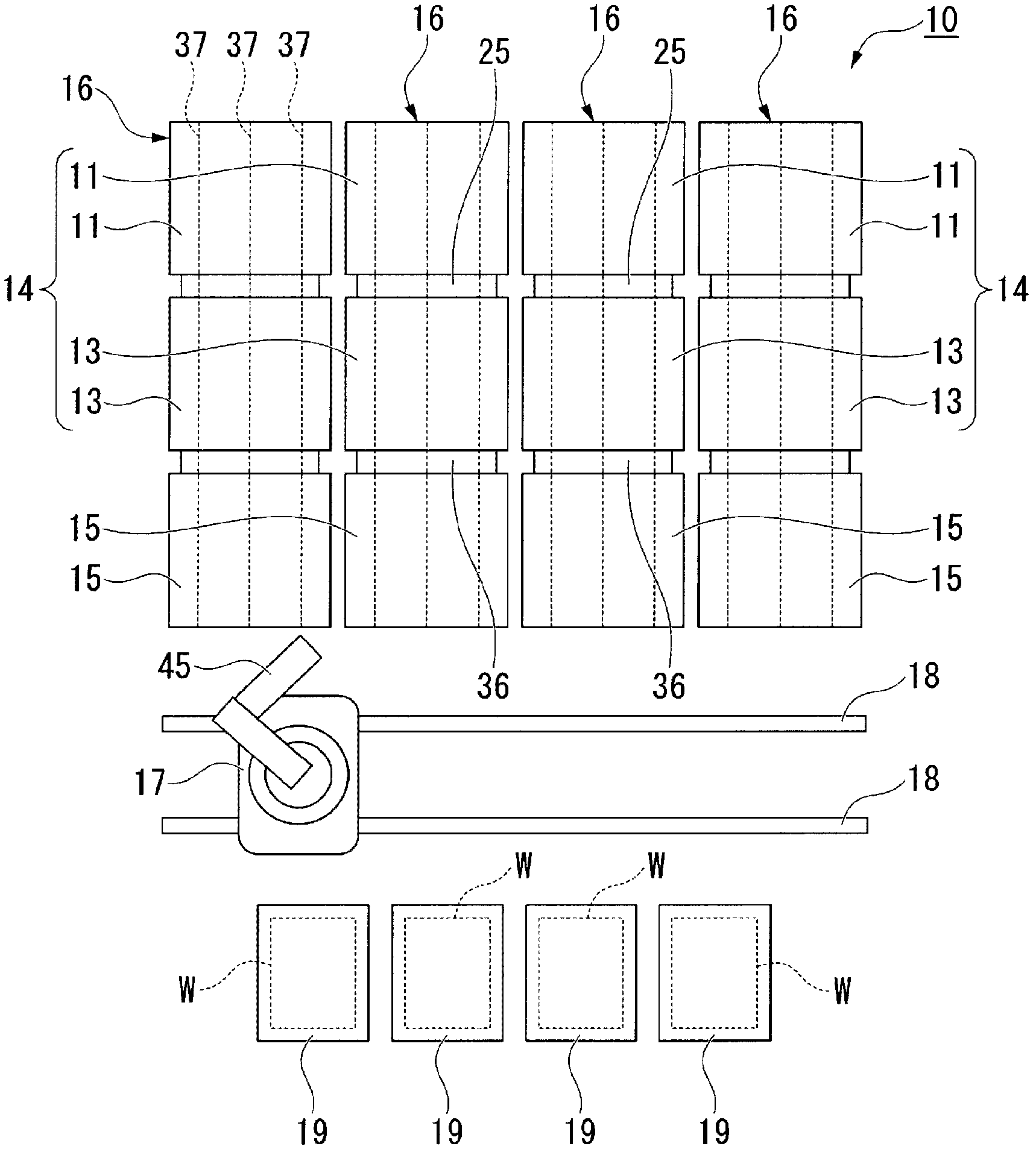

[0037] figure 1 It is a figure schematically showing the structure of a film formation apparatus.

[0038] like figure 1 As shown, the film forming apparatus 10 includes: a film forming chamber 11 , a loading and unloading chamber 13 , a substrate loading and unloading chamber 15 , a substrate loading and unloading robot 17 , and a substrate storage box 19 .

[0039] In the film formation chamber 11 , for example, a microcrystalline silicon film can be formed on a plurality of substrates W at the same time.

[0040] The loading / unloading chamber 13 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com