Method for manufacturing latex material underlaying appliance

A manufacturing method and technology of latex, applied in household appliances, applications, interior decoration, etc., can solve the problems of slow production speed, high manufacturing cost, rough appearance of finished products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment is hereby combined with the drawings to describe the present invention in detail.

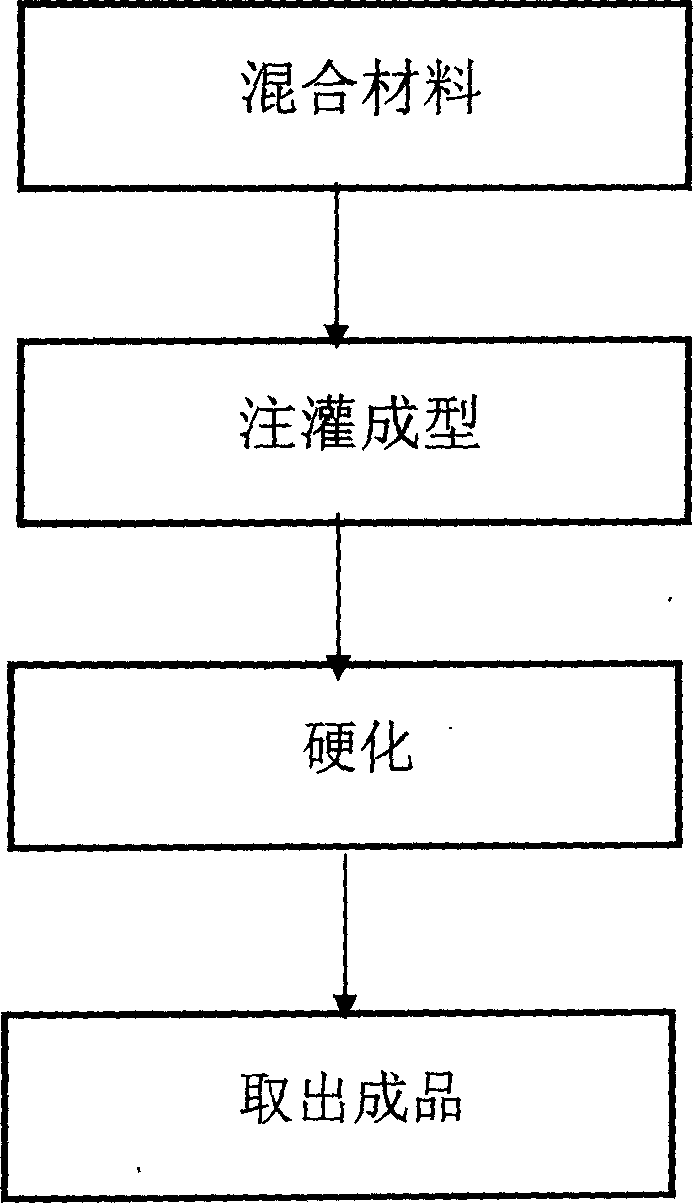

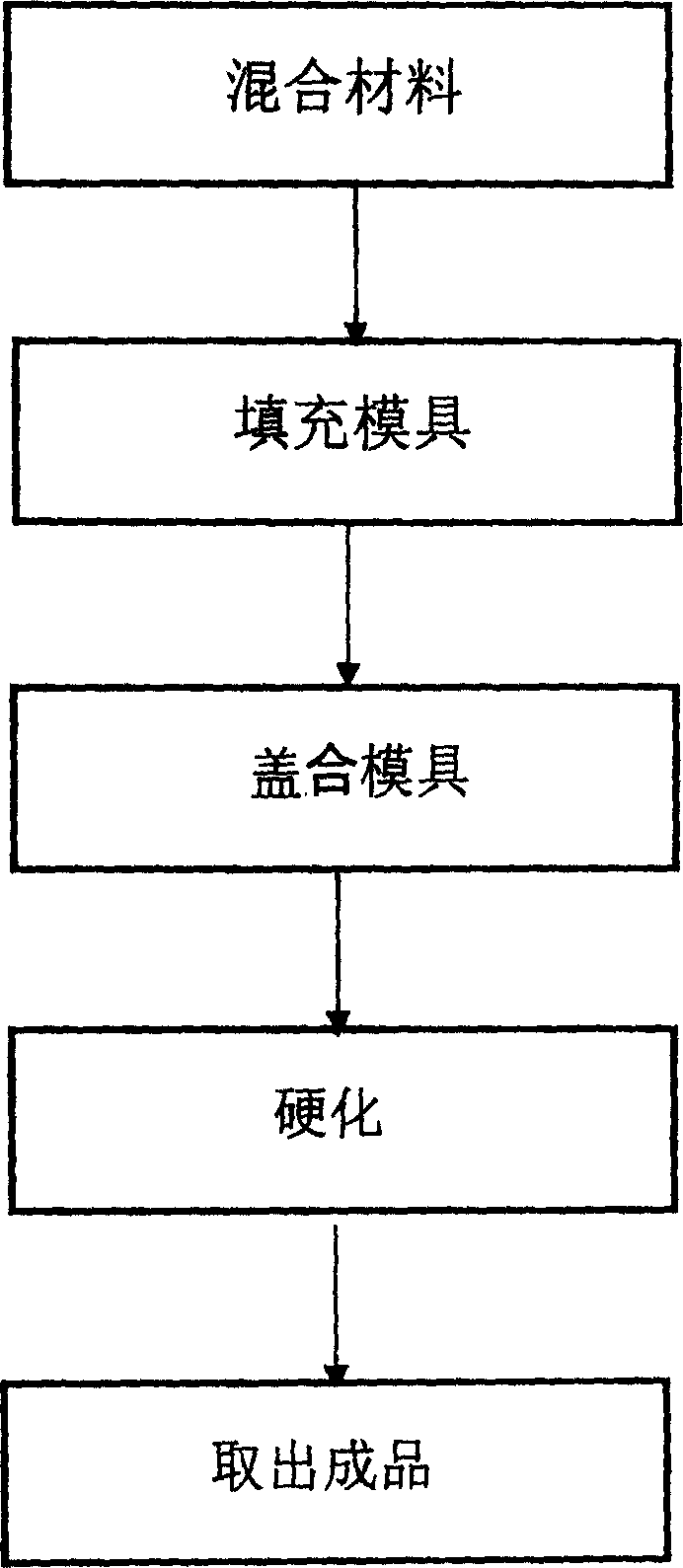

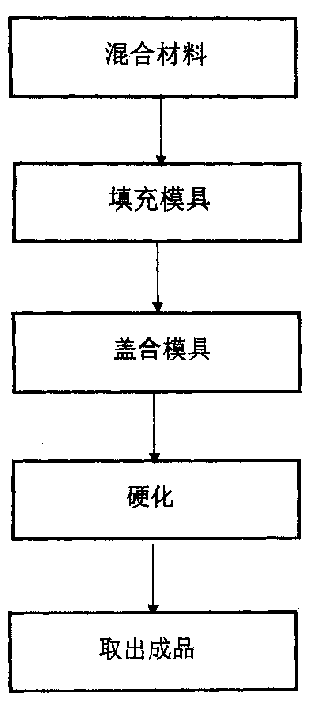

[0017] The manufacturing method of latex cushion provided by a preferred embodiment of the present invention comprises the following steps:

[0018] a. Stir and mix the main raw material of latex, a predetermined amount of additives and air in a raw material barrel, so that all materials are fully mixed and foamed.

[0019] b. Pour the mixed and foamed material in step a into a forming mold with a hollow mold cavity of a predetermined shape through a circular conveying pipe.

[0020] c. Applying a predetermined temperature to make the mixed material in the forming mold harden and set.

[0021] d. Open the forming mold, and take out the hardened and shaped mixed material from the mold to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com