Fishing boat wind shield making process

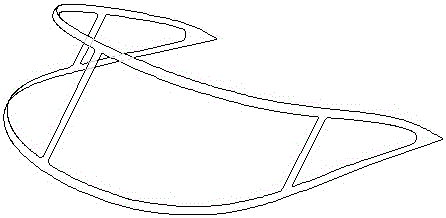

A manufacturing process and technology for fishing boats, which are applied to ships, ship parts, fishing boats, etc., can solve the problems of inconvenient installation of glass on aluminum alloy windshields, low connection strength, and unreliable connections, and achieve high clamping force and external light. Beautiful, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention relates to a fishing boat windshield manufacturing process, the process includes the following steps:

[0020] Step 1. Clean the mold: the mold is divided into an inner frame mold for making an inner frame and an outer frame mold for making an outer frame; use adhesive tape to protect the inner frame mold and the outer frame mold, and the inner frame mold and the outer frame The part where the glass is installed in the middle of the mold is pasted and protected with white paper;

[0021] Step 2, inner frame and outer frame production:

[0022] Spray gel coat on the surface of the inner frame mold. After the gel coat is cured, lay the first layer of glass fiber felt, and roll it in place. After it is completely cured, it will be polished to remove burrs, hollows and other parts; lay the second layer and the third layer. One layer of glass fiber mat, after the glass fiber mat is cured, demould to obtain the inner frame;

[0023] Spray gel coat on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com