Tandem type pile pressing machine and construction process thereof

A technology of pile driver and static pile driver, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., and can solve the problems of easy-sliding top-press structure, inconvenient pile entry, and easy clamping of damaged pile sections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

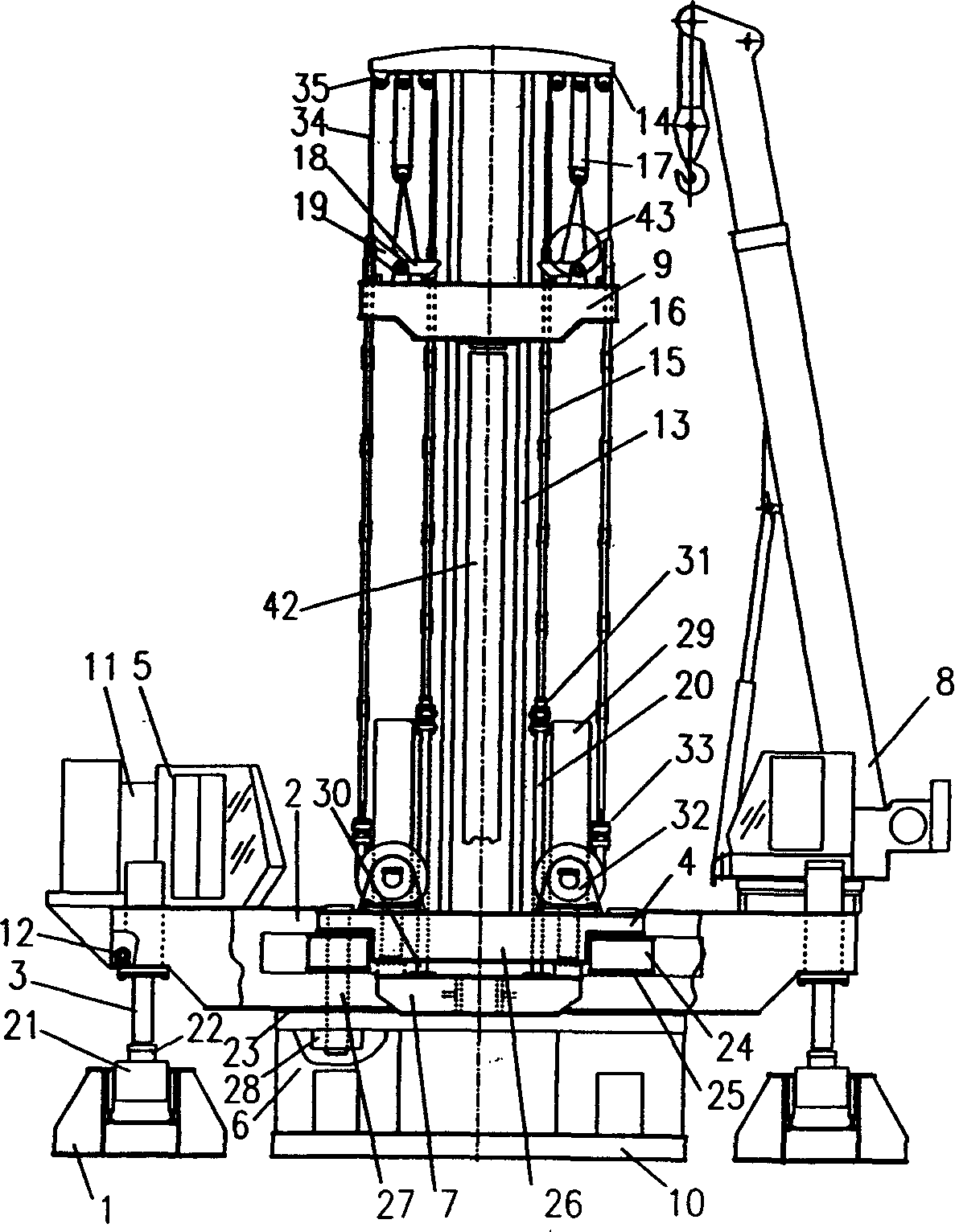

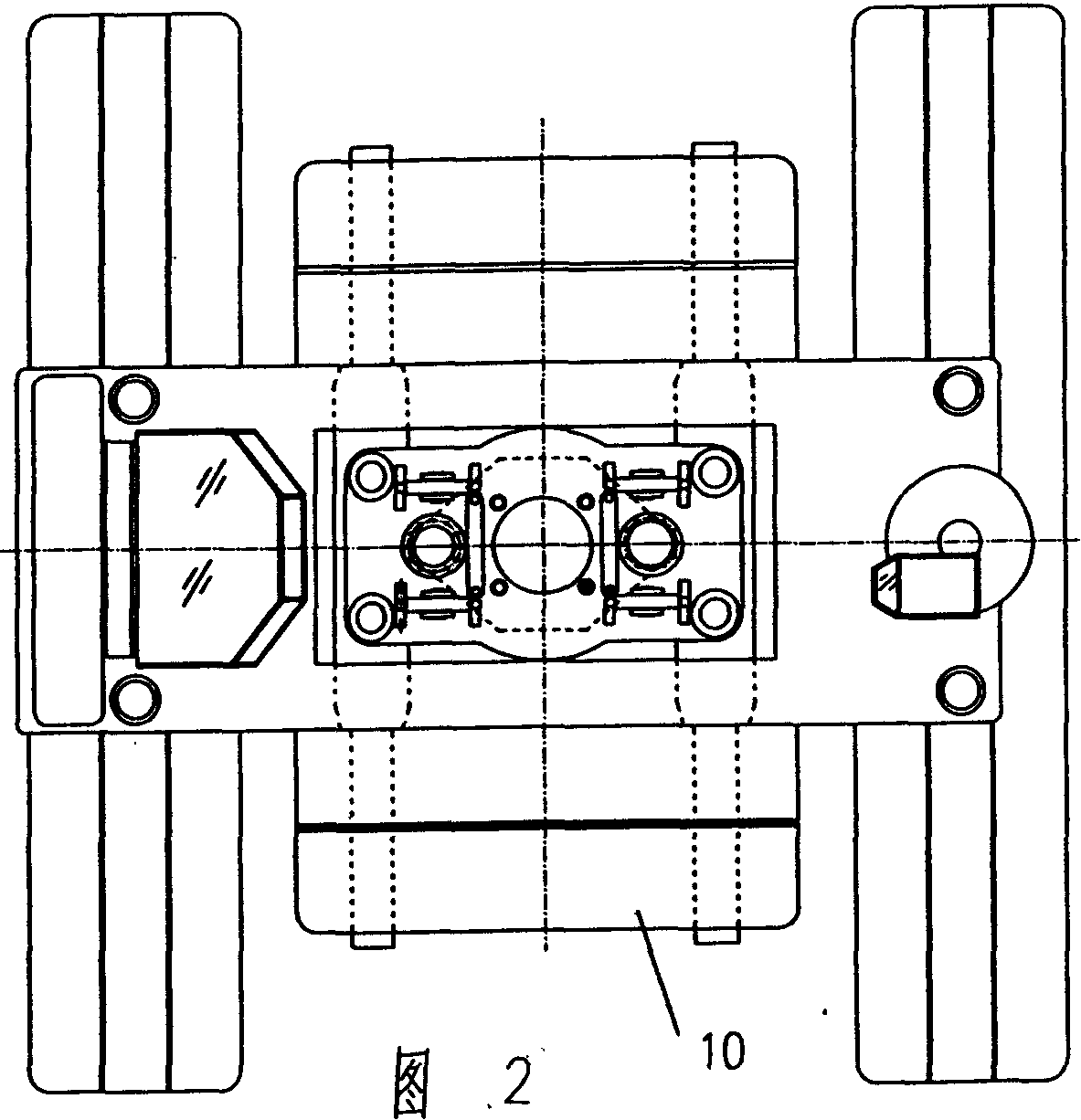

[0024] The structure of the tandem pile driver (tie rod type) is as follows: figure 1 , 2, it is mainly composed of long support 1, main beam 2, outrigger 3, mobile pile support platform 4, operating system 5, center support seat 6, active pile pressure beam 7, pile hanging mechanism 8, follow-up Pressure pile beam 9, counterweight system 10, electrical system 11, hydraulic system 12, pile pressure bracket 13, top beam 14, inner tie rod 15, outer tie rod 16, winch 17, inner bearing claw 18, outer bearing claw 19, The winding chain 20 consists of several parts. The two ends of the main beam 2 each have two telescopic outrigger cylinders 3, and each outrigger cylinder is connected to the respective walking trolley 21 through a ball joint 22, and the walking trolley is supported on On the rail of long support 1. An electrical system 11 and an operating system 5 are installed on the left end of the platform of the main beam 2, a hydraulic system power station 12 is installed in t...

Embodiment 2

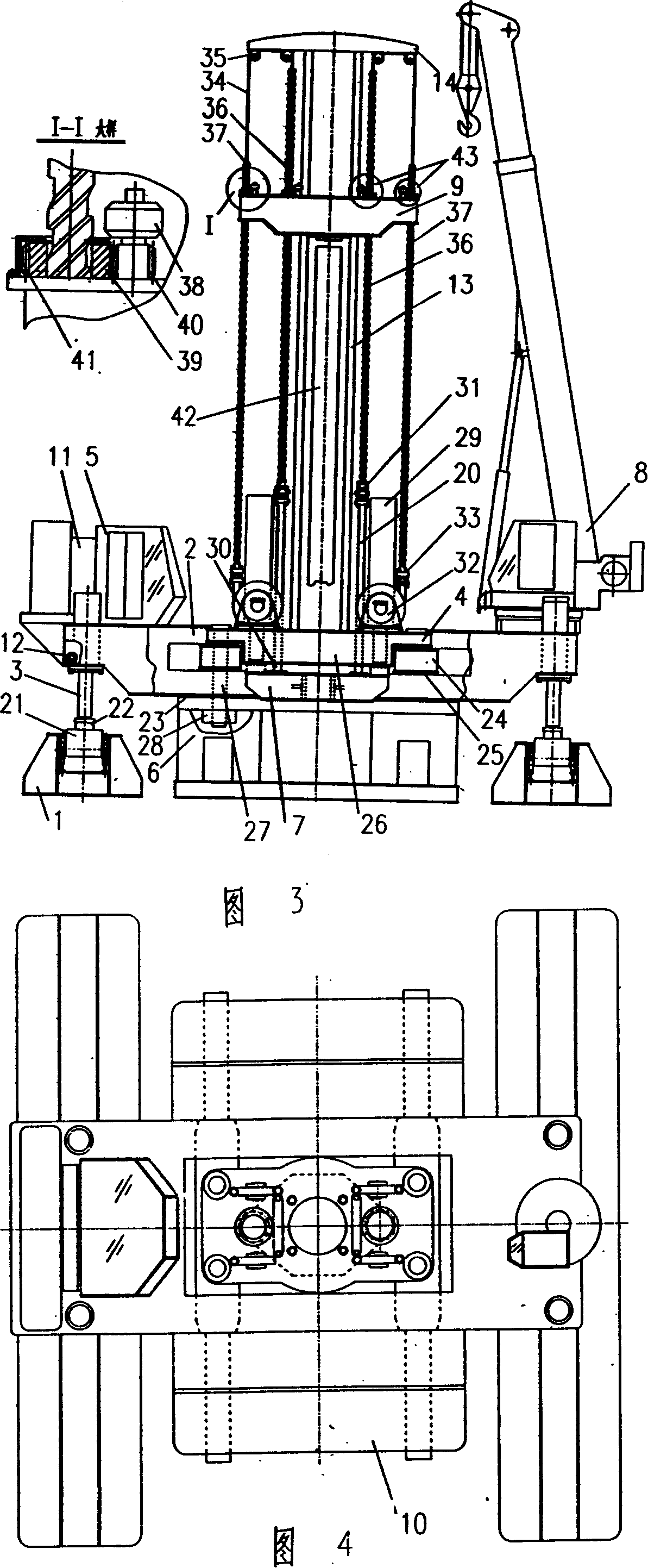

[0029] The structure of the series pile driver (screw type) is shown in Figures 3 and 4. The pile driver uses an inner screw mandrel 36 and an outer screw mandrel 37 to replace the inner tie rod and outer tie rod of Embodiment 1 respectively, and the hoist is eliminated. and load-bearing claws, and four oil motors 38 are housed on the follower pressure pile beam 9, and a transmission gear 40 is housed at the output shaft end of each oil motor, and screw nuts 39 are set on the inner and outer screw rods, and the nuts There is a ferrule 41 with a notch on the outside, the direction of the notch faces the oil motor, so that the gear and the nut are engaged at the outer point, the ferrule is fixed on the follower pressure pile beam 9, the fixed pulley 35 on the upper end of the screw mandrel and the top beam Winding soft rope 34 links to each other.

[0030] When the machine presses the single-girder pile with the dynamic pile beam (such as Figure 6 As shown), first put the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com