Pneumatic flexible ball-joint

A ball joint and flexible technology, applied in the field of ball joints, can solve the problems of affecting the implementation effect, large space size, complex structure, etc., and achieve the effects of large implementation value, simple control, and flexible movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

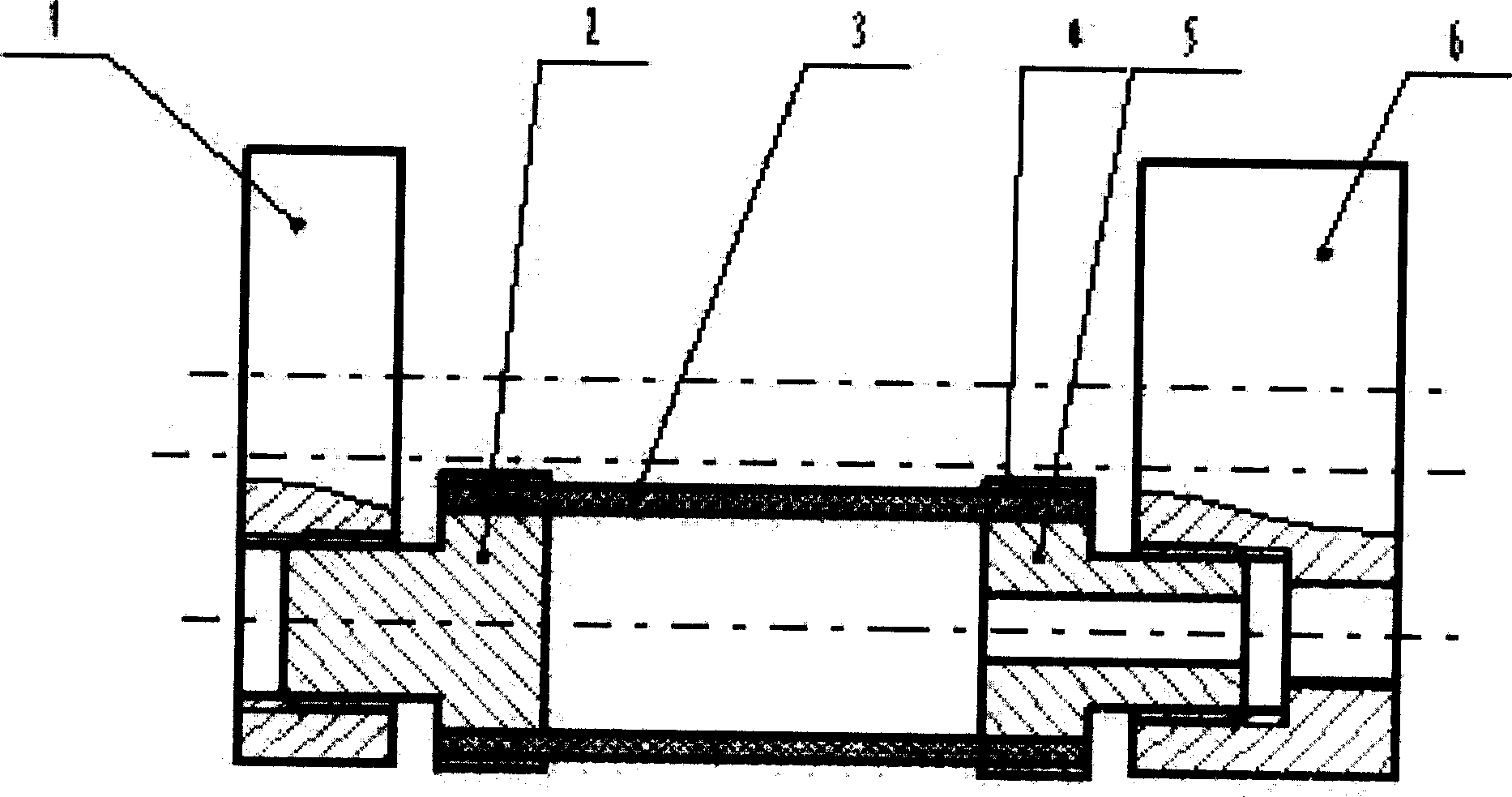

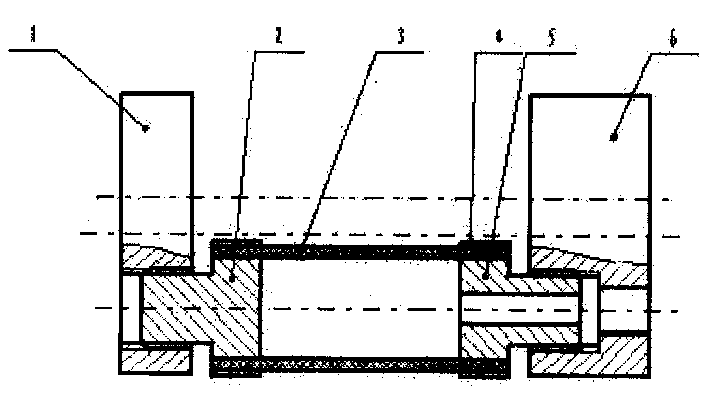

[0008] figure 1 is an example of the present invention. Such as figure 1 As shown, the embodiment of the present invention is: a pneumatic flexible ball joint, which is characterized by a left cover 1, a left seal head 2, a rubber tube 3, a fastening ring 4, a right seal head 5, and a right cover 6. Three threaded holes are arranged at intervals of 120 degrees on the left cover 2, and three stepped holes are arranged at intervals of 120 degrees on the right cover 6, and the large holes of the stepped holes are threaded holes, and the left and right ends of the three same rubber tubes 3 Connect with the left and right sealing heads and the right sealing head 5 respectively to ensure the tightness of the connection between the rubber tube 3 and the left and right sealing heads and the right sealing head 5. The left and right sealing heads are connected to the left cover 1 through ribs, and the fastening ring 4 is tightly sleeved. Outside the rubber tube 3, and located at one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com