Method of servicing textile machine workstation as well as the textile machine itself and a kit for textile machine additional outfit

A working position, textile machine technology, applied in textiles and papermaking, spinning machines, transportation and packaging, etc., can solve problems affecting coil winding characteristics, faults, etc., and achieve the effect of improving cutting reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

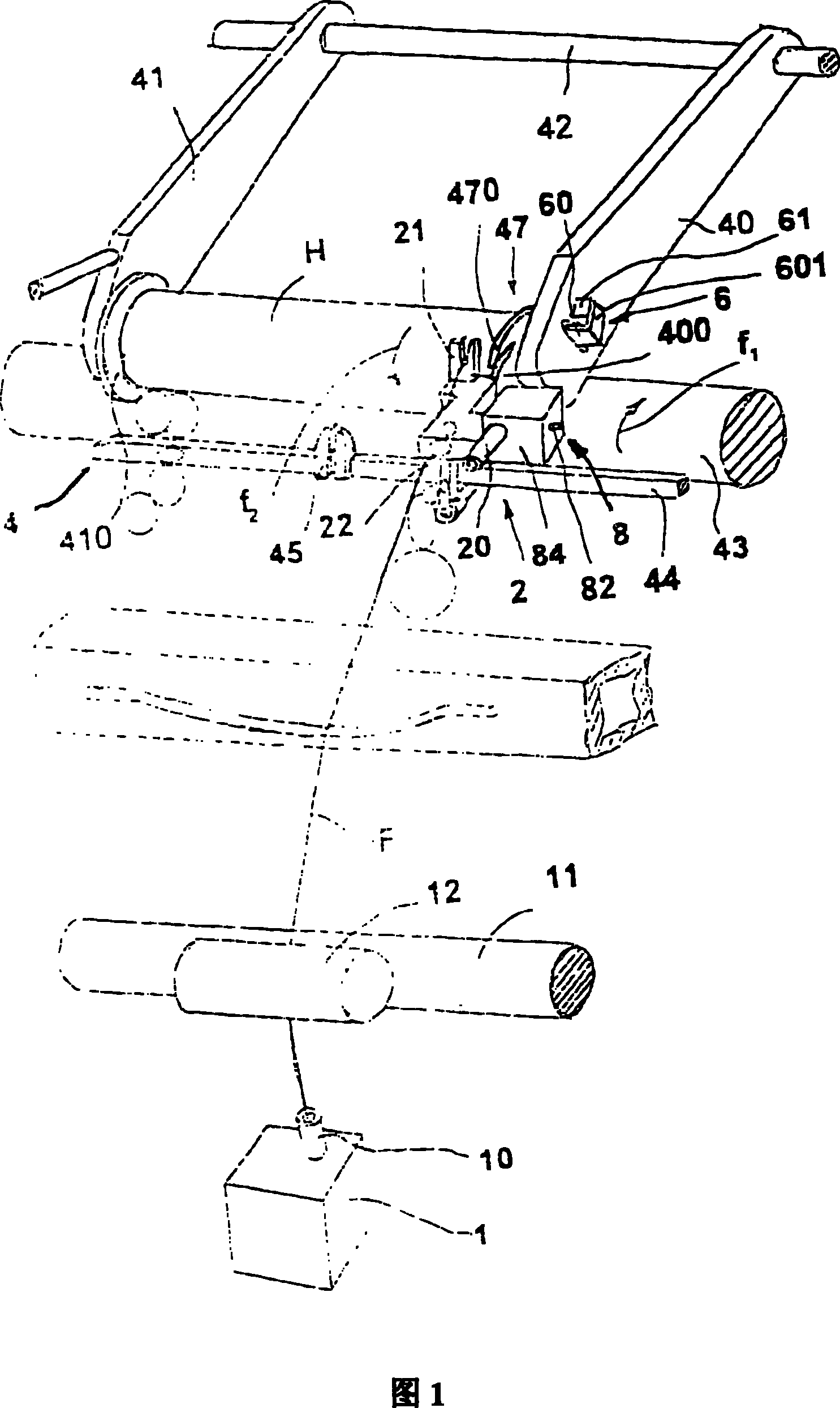

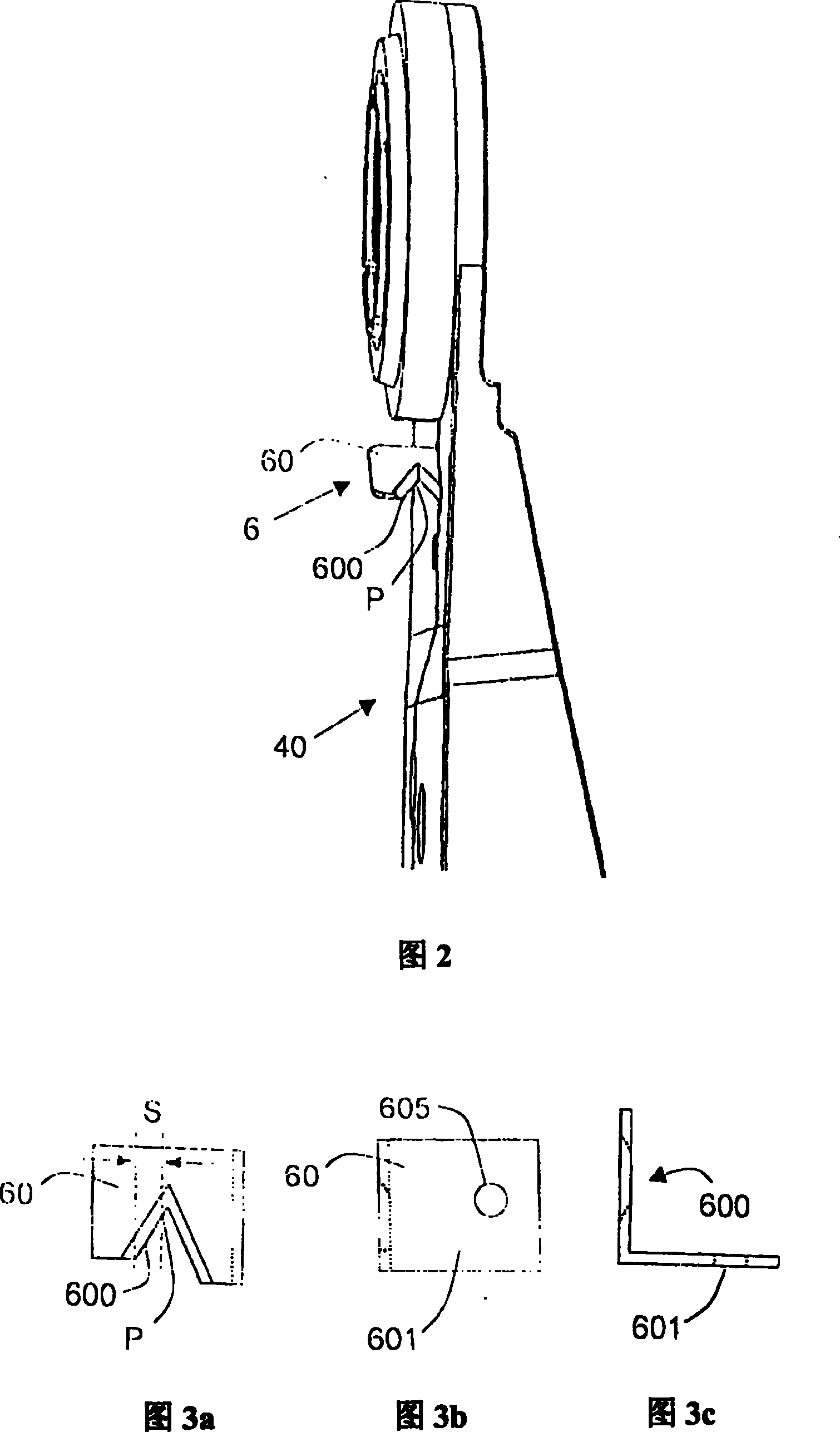

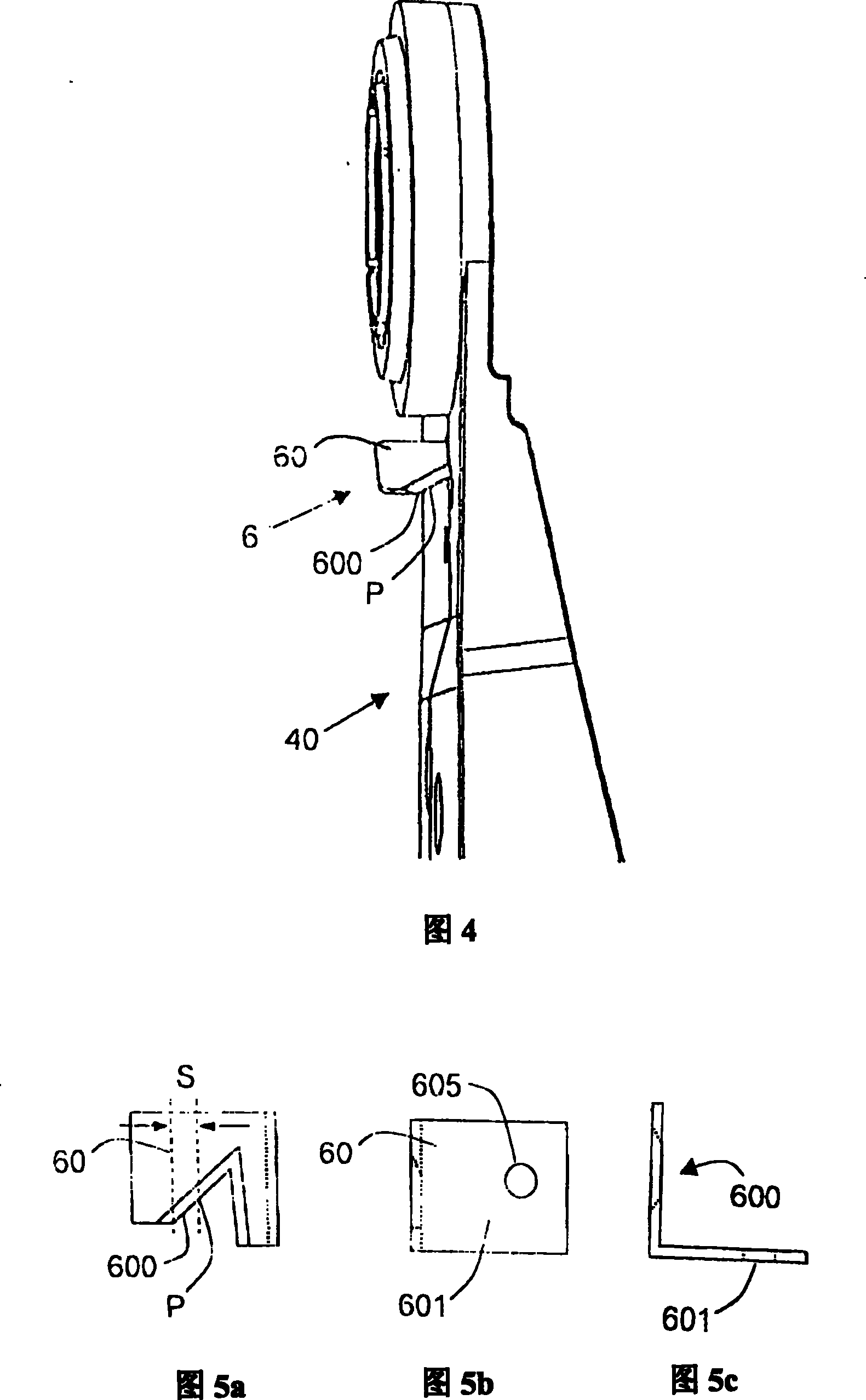

[0040] figure 1A working position of an open-end spinning machine is shown with an open-end spinning device 1 having a draw-off tube 10 through which the yarn F can be spun from the free-end by means of draw-off rollers 11, 12 The device 1 is pulled out so as to be guided to a winding device 4 . The winding device has two winding arms 40 and 41 pivotably mounted on a shaft 42, between which two sleeve discs 400 mounted rotatably in the winding arms 40 and 41 can be used. and 410 are loaded into a hollow sleeve H on which the yarn F is to be wound. Here, one of the sleeve disks, in the exemplary embodiment the sleeve disk 400 , is designed as catch device 47 and has a plurality of catch hooks 470 for this purpose.

[0041] In order to present the yarn F to be received by the intercepting device 47, a presenting device 2 is provided. It has a yarn delivery device 20 and a yarn introduction device 21 , which are arranged on a common support 22 , which in the exemplary embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com