Low molecular polymer modification polythene composite water-proof coiled material

A waterproof membrane and polymer technology, applied in the direction of textiles and papermaking, etc., can solve the problems of poor processability, increased extrusion heat moment, and decreased output, and meet production technical requirements, reduce melt viscosity, and melt The effect of body index increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment one (ternary blending scheme)

[0012] Linear low density polyethylene (grade 7042) 100kg;

[0014] Low-density polyethylene (brand 1F7B) 20kg;

[0015] Auxiliary masterbatch 4kg.

[0016] Stir and mix the above materials in the barrel evenly, suck them into the extruder with a feeder, melt and blend them in the extruder, cast them through the die to form a film, and then directly press and heat-melt them on both sides through the composite roller. Composite with polypropylene non-woven fabric, cooling and winding to form a waterproof membrane product.

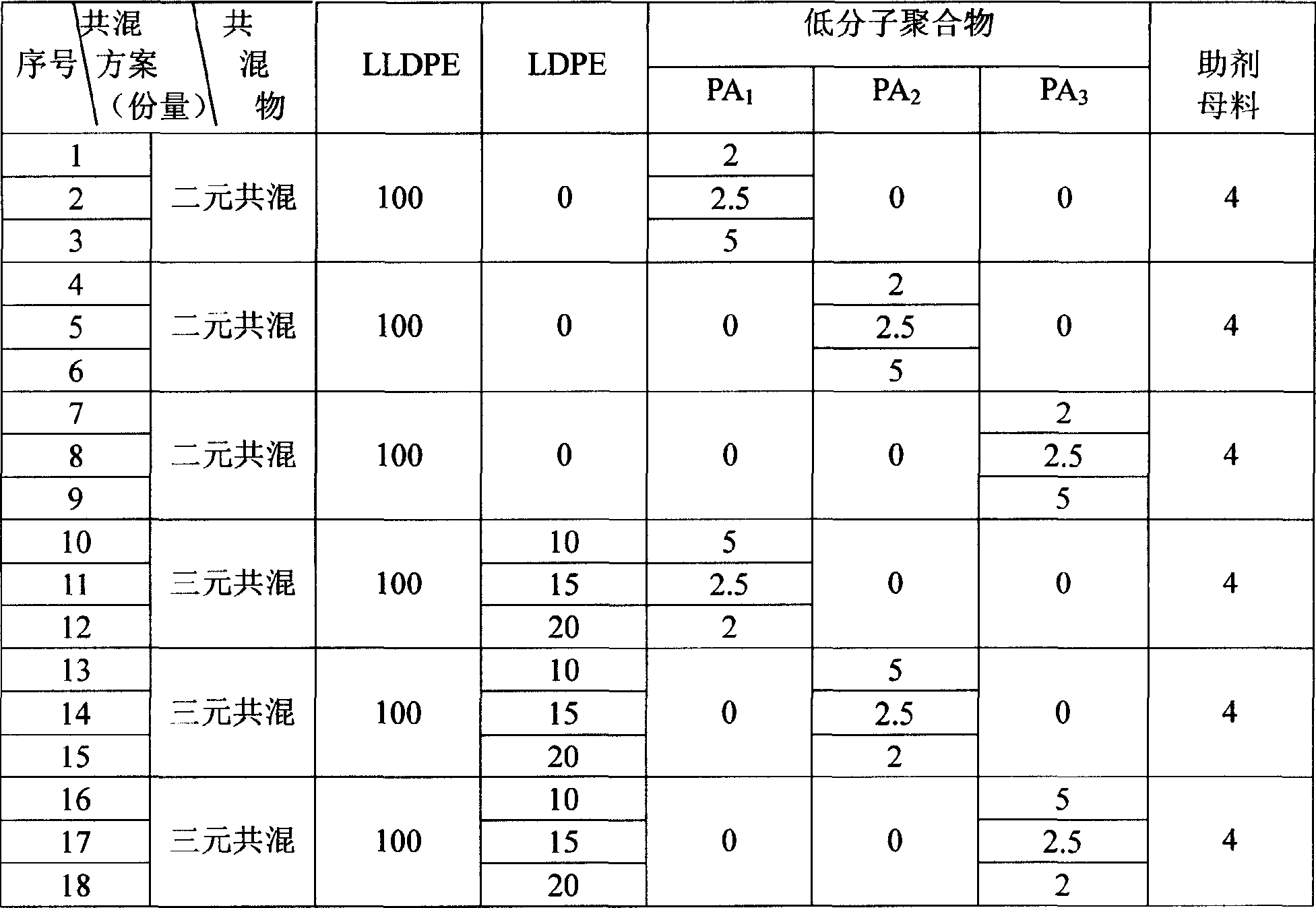

[0017] The formulations of other examples are shown in Table 1, and 18 blending modification schemes are listed in Table 1. Wherein there are 9 kinds of binary blending schemes and 9 kinds of ternary blending schemes (including embodiment one).

[0018] In the table, LLDPE is the abbreviation of linear low-density polyethylene, and LDPE is the abbreviation of low-density po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com