Electric flow control valve

A flow control valve, electric technology, applied in heating and ventilation control systems, refrigerators, valve devices, etc., can solve the problem that the rotor 33 cannot rotate, and achieve the effect of improving the reliability of the action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

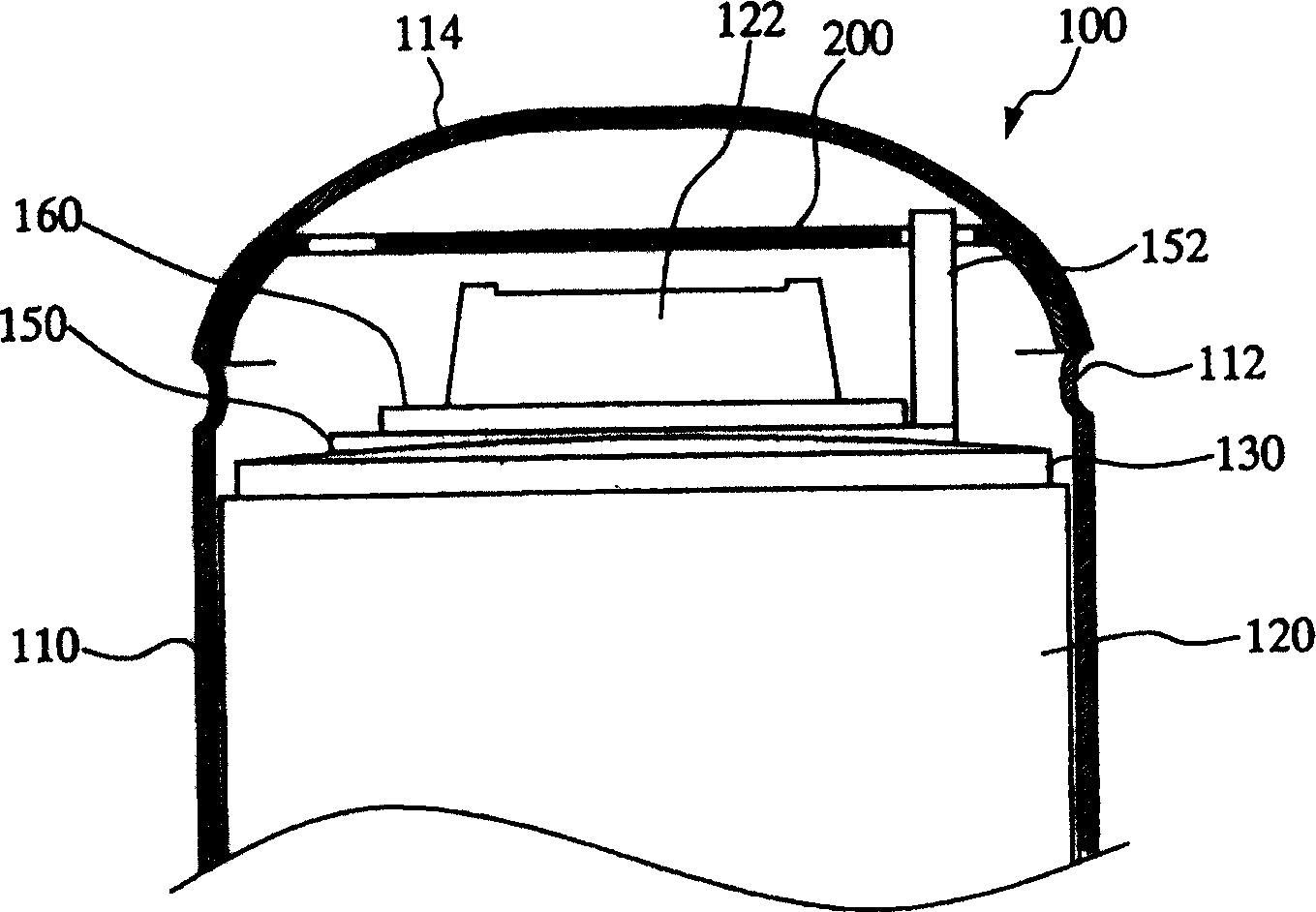

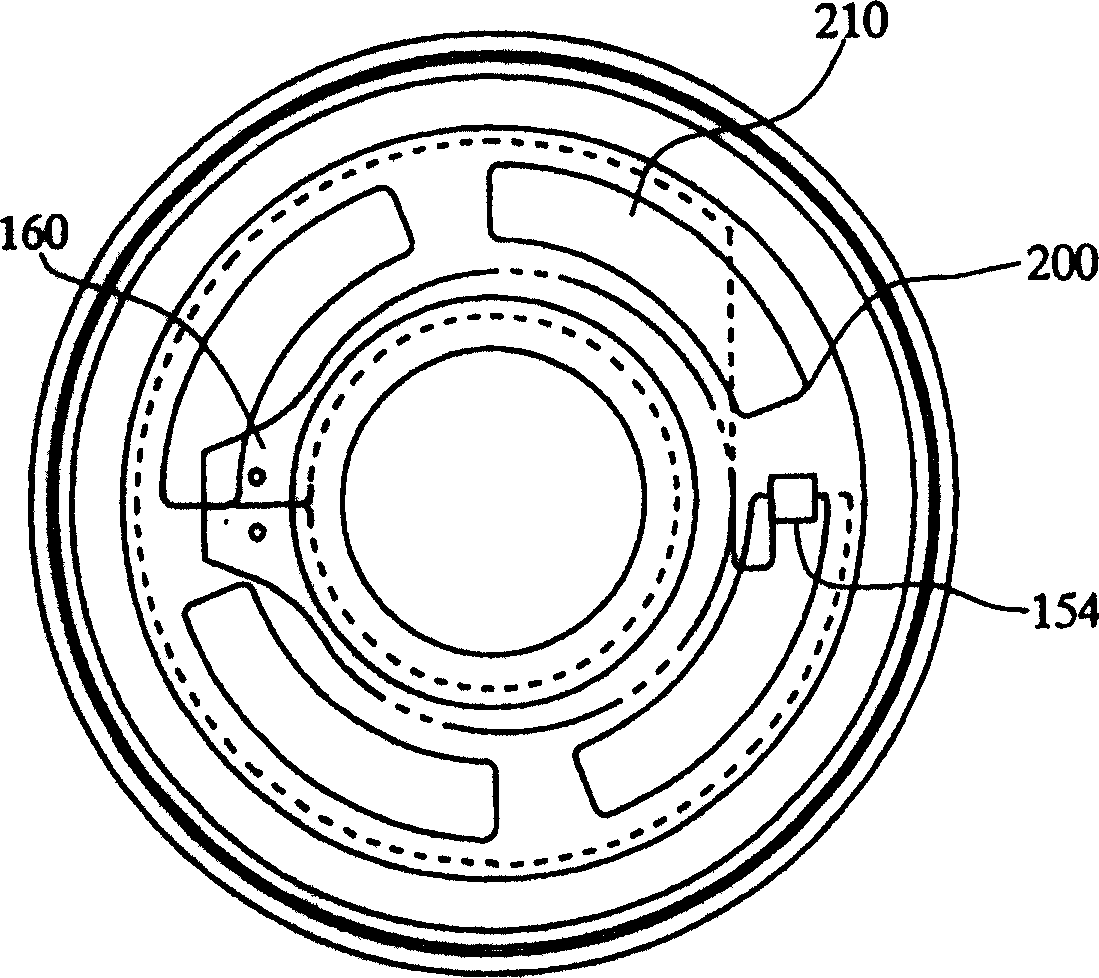

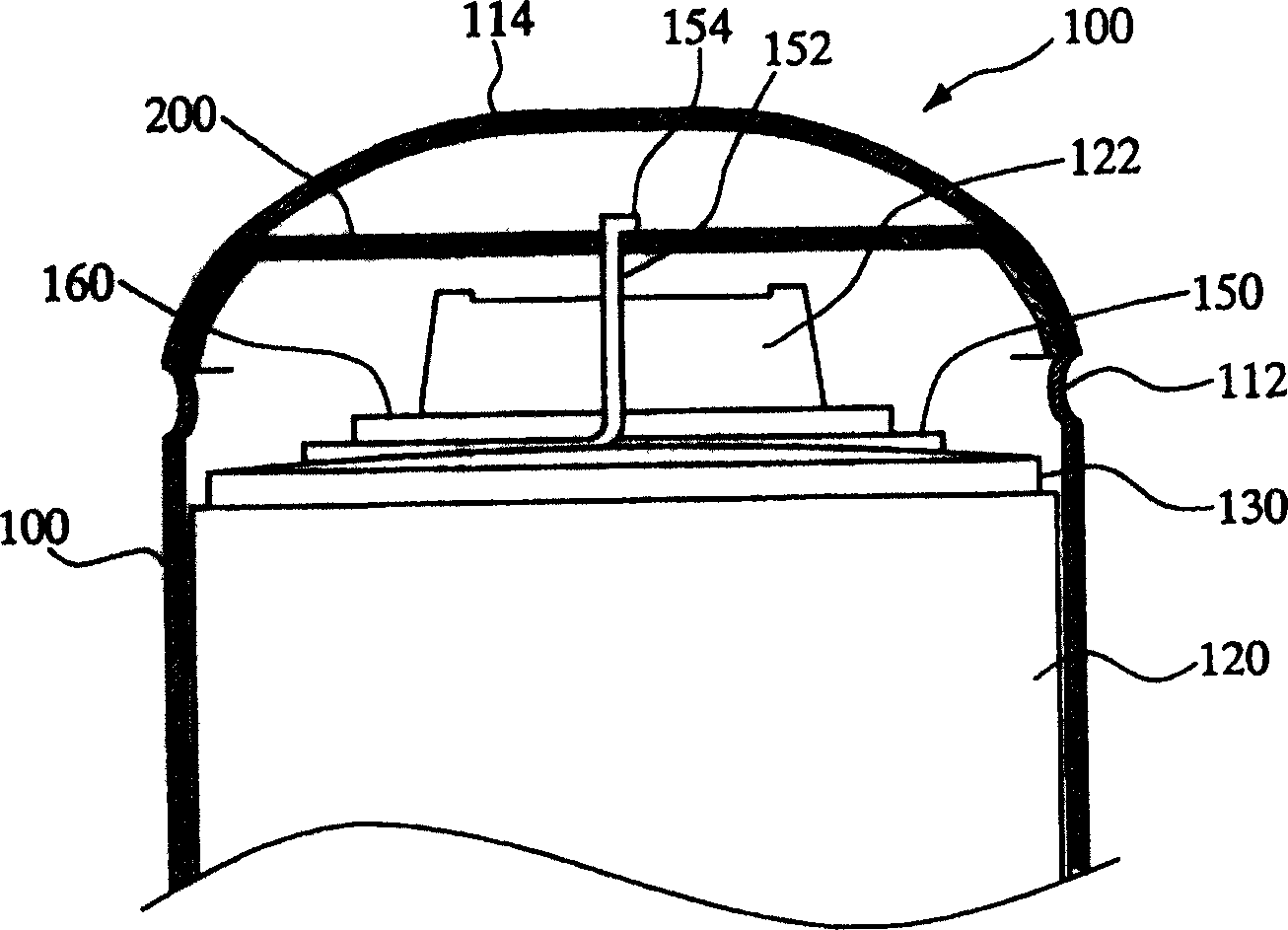

[0047] Hereinafter, embodiments of the present invention will be described with reference to the drawings. 1 and 2 are diagrams showing main parts of an electric flow control valve 100 according to this embodiment, and Figure 6 The existing electric flow control valve shown also shows the upper structure of the rotor 120 formed by the sleeve and the magnet, and the basic structure and function are the same as those of the rotor 120. Figure 6 The conventional electric flow control valve shown is the same, and only the above-mentioned rotor is shown in FIG. 1 and FIG. 2 because only the upper structure of the rotor equipped with the limiter is different. In addition, Fig. 1 shows the structural diagram (a) and the upper surface diagram (b) of the top 114 structure of the airtight casing of the electric flow control valve, and Fig. 1 (b) shows that the top 114 of the airtight casing of Fig. 1 (a) is halfway The top view of the cut state. And Fig. 2 shows the structural diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com