Motor assembly and vacuum cleaner having the same

A technology for vacuum cleaners and vacuum cleaners, which is applied to the installation of motor fan components, vacuum cleaners, suction filters, etc. It can solve the problems of complex manufacturing process of vacuum cleaner 100, users cannot enjoy quiet cleaning work, and increased manufacturing costs. Reduced process, reduced manufacturing cost, noise prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

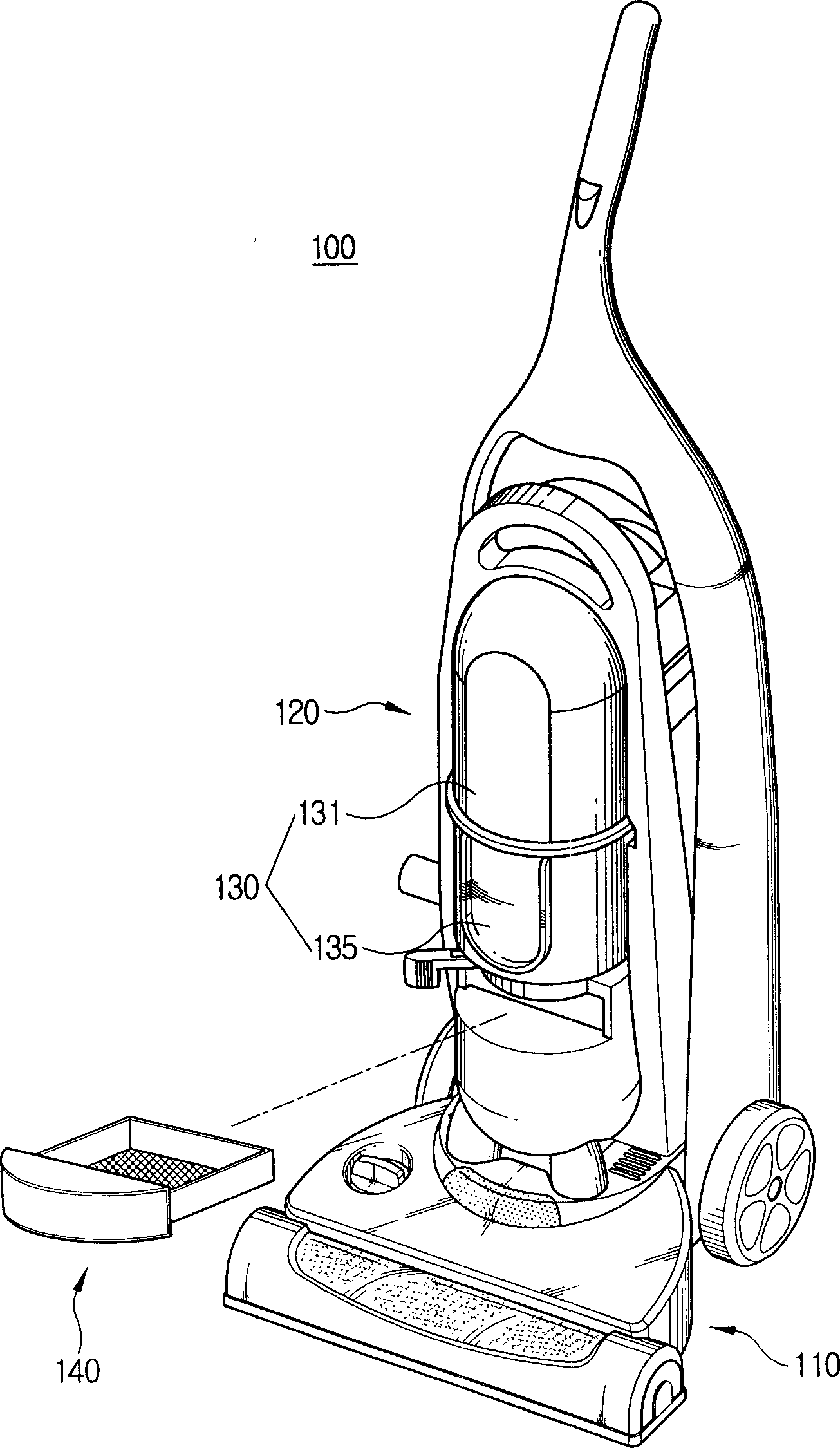

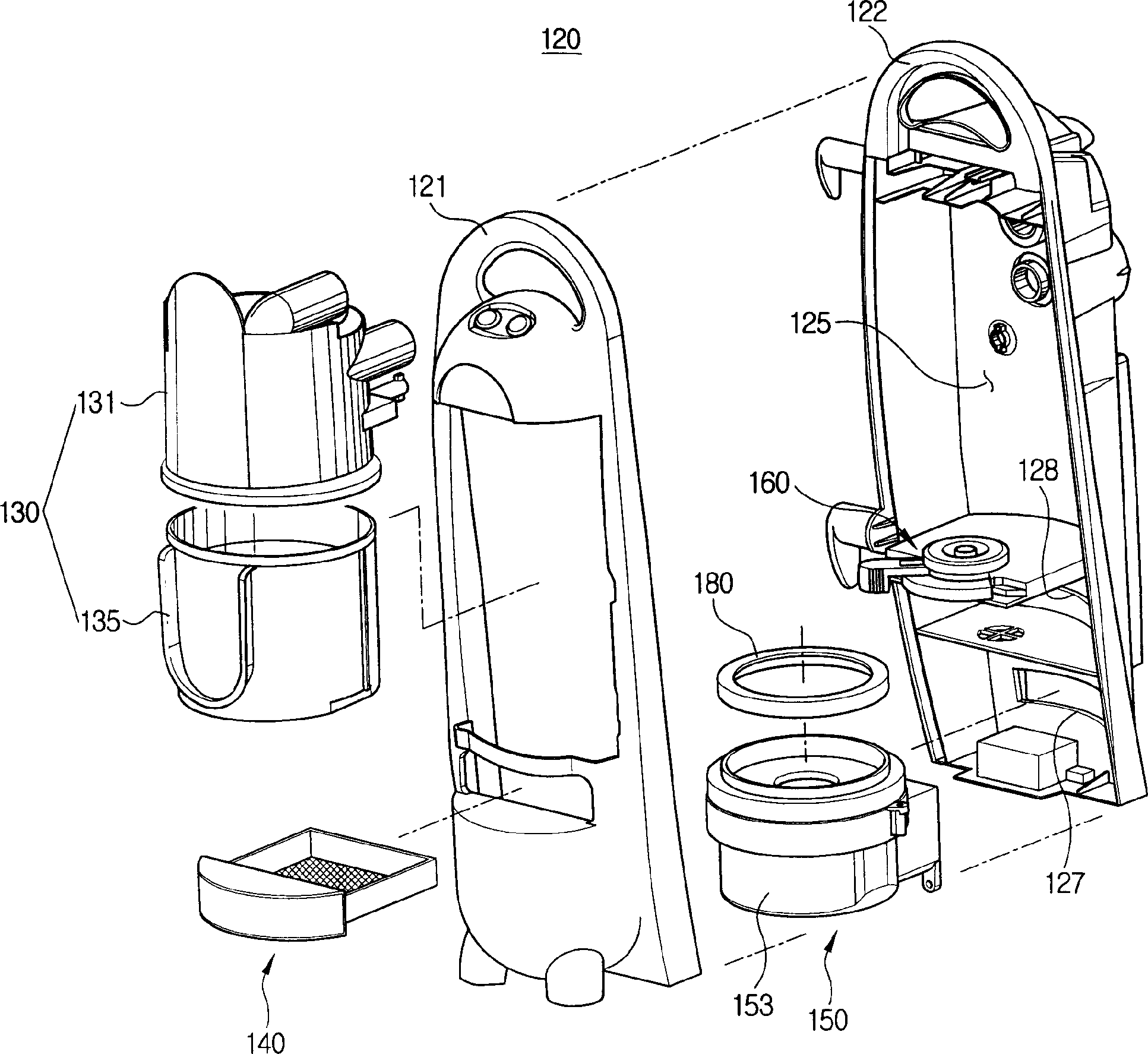

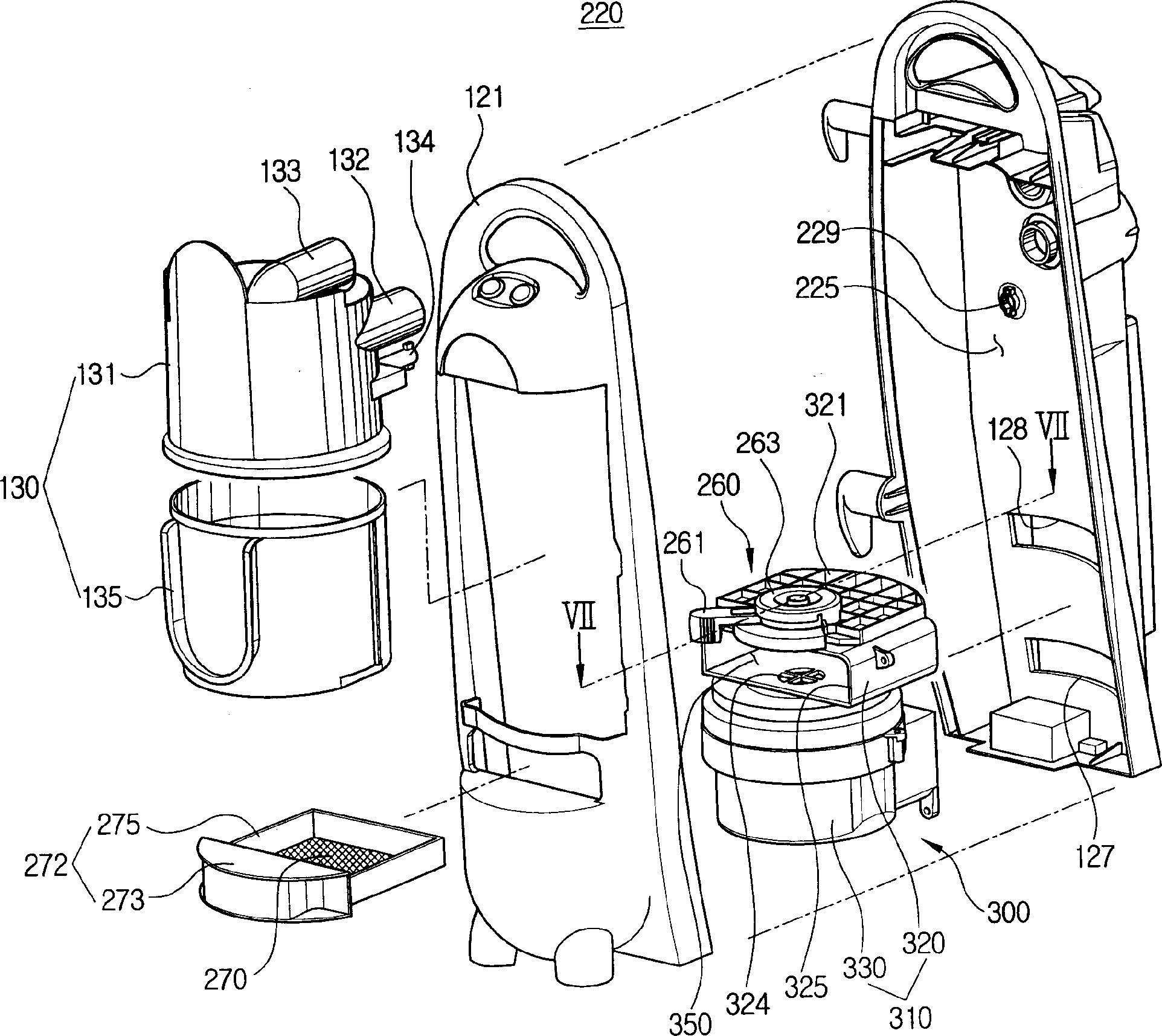

[0028] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. for those with figure 1 and figure 2 Like elements of the conventional vacuum cleaner shown have been given the same reference numerals.

[0029] see Figure 3-7 , The vacuum cleaner according to the preferred embodiment of the present invention includes a cleaner body 220 , a cyclone dust collecting device 130 and a motor assembly 300 . Such as image 3 As shown, the cleaner body 220 includes a dust collection chamber 225 having a discharge port 127 . The motor assembly 300 is disposed in the cleaner body 220 . Therefore, through the suction assembly 110 (see figure 1 ) through the dust suction opening (not shown) from the outside in order to pass through the dust collection chamber 225 and the motor assembly 300, and then be discharged out of the main body 220 of the vacuum cleaner through the discharge port 127.

[0030] The cyclone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com