Working table device for table type applicator

A coating machine and workbench technology, which is applied in the direction of surface coating liquid devices, coatings, manufacturing tools, etc., can solve the problems of increasing installation space, increasing transportation costs, and increasing width dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

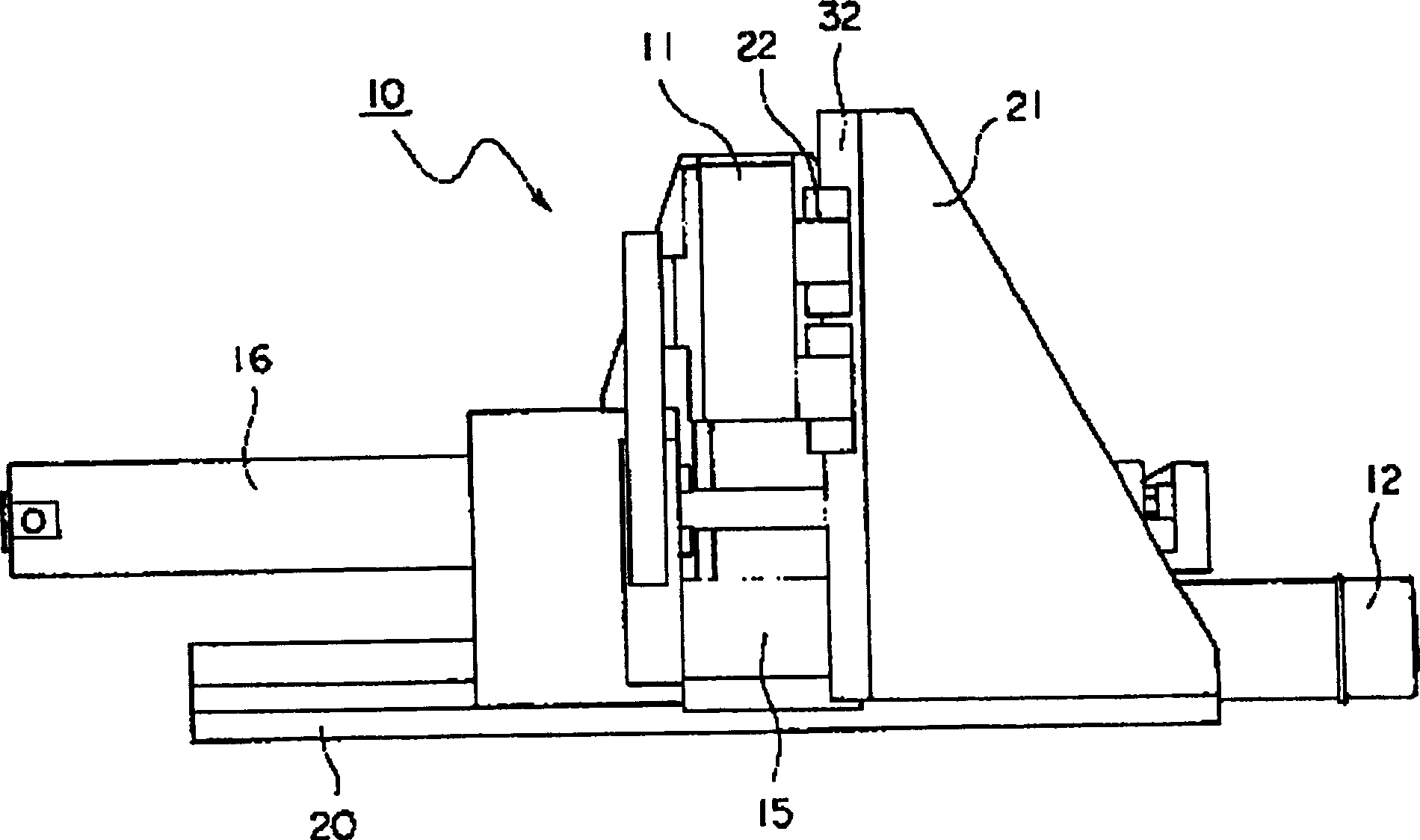

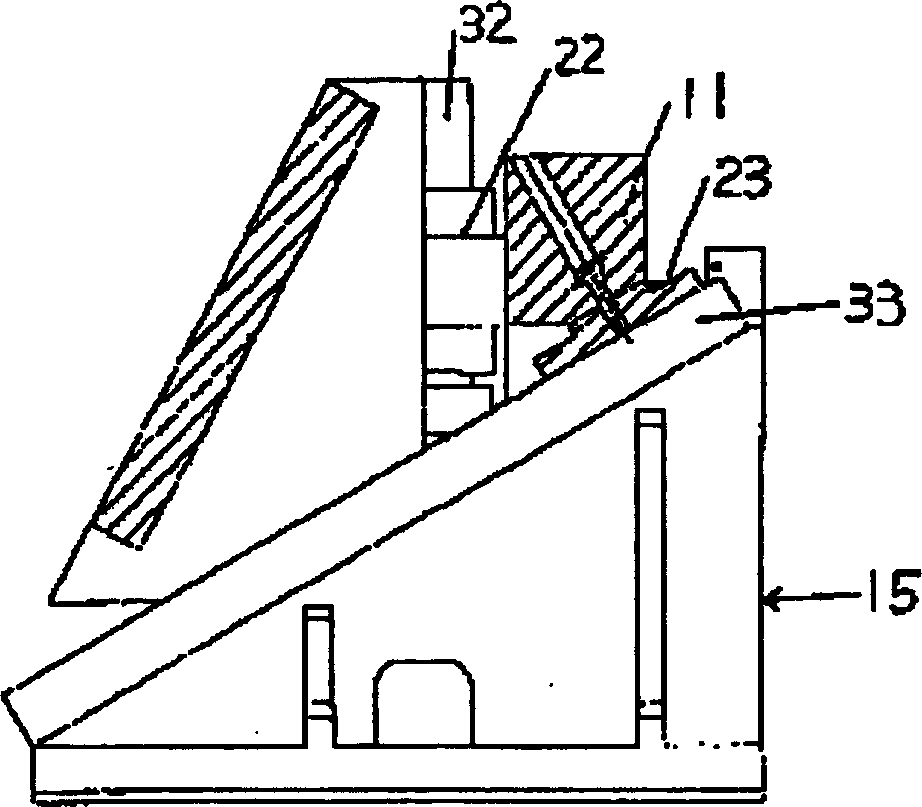

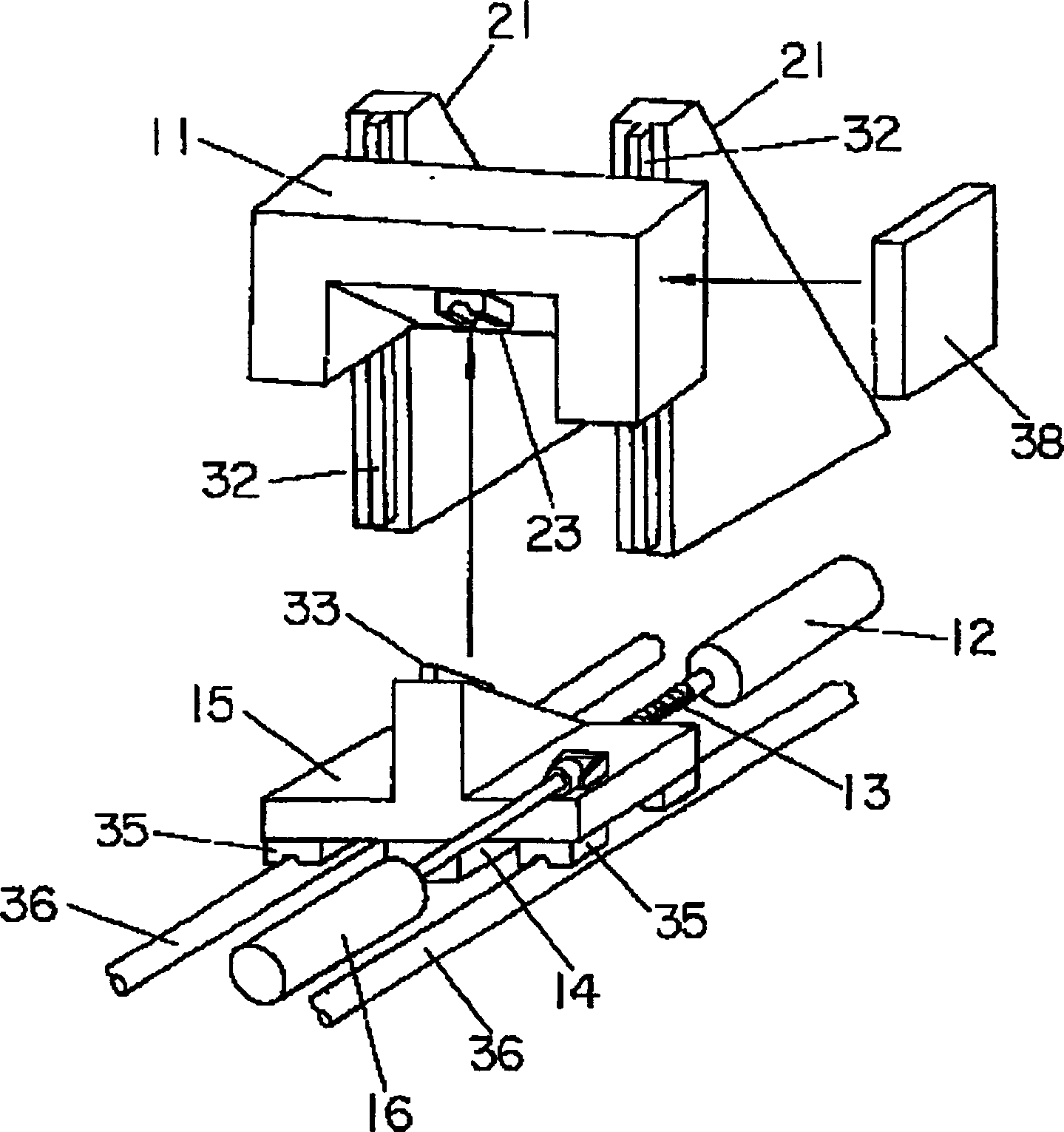

[0039] Refer below Figure 1 ~ Figure 3Embodiments of the table device for a table-top coater according to the present invention will be described. The workbench device of the present invention is characterized in that it improves the Figure 7 Illuminated Z-axis drive mechanism. Thus, in Figure 1 ~ Figure 3 Only the Z-axis drive mechanism is shown in the figure, and only the Z-axis drive mechanism will be described below. That is, it can be considered that the structure and function other than the Z-axis drive mechanism Figure 4 , Figure 5 The same as shown and described.

[0040] If used Figure 4 , Figure 5 As described above, two guide rails 110A, 110B extending parallel to each other are provided on both sides of the stone table 160 corresponding to both sides of the substrate table 100, and are arranged so as to be movable along these guide rails 110A, 110B. Y-axis drive mechanisms (first slide mechanisms) 120A, 120B constituted by linear motors.

[0041] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com