Brake tongs device

The technology of a brake caliper and a resistance device is applied in the field of brake caliper devices of disc brakes, which can solve the problems of damage to the interference part and accelerated wear of the lever rotating part, and achieve the effects of reducing impact sound, inhibiting wear and improving operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

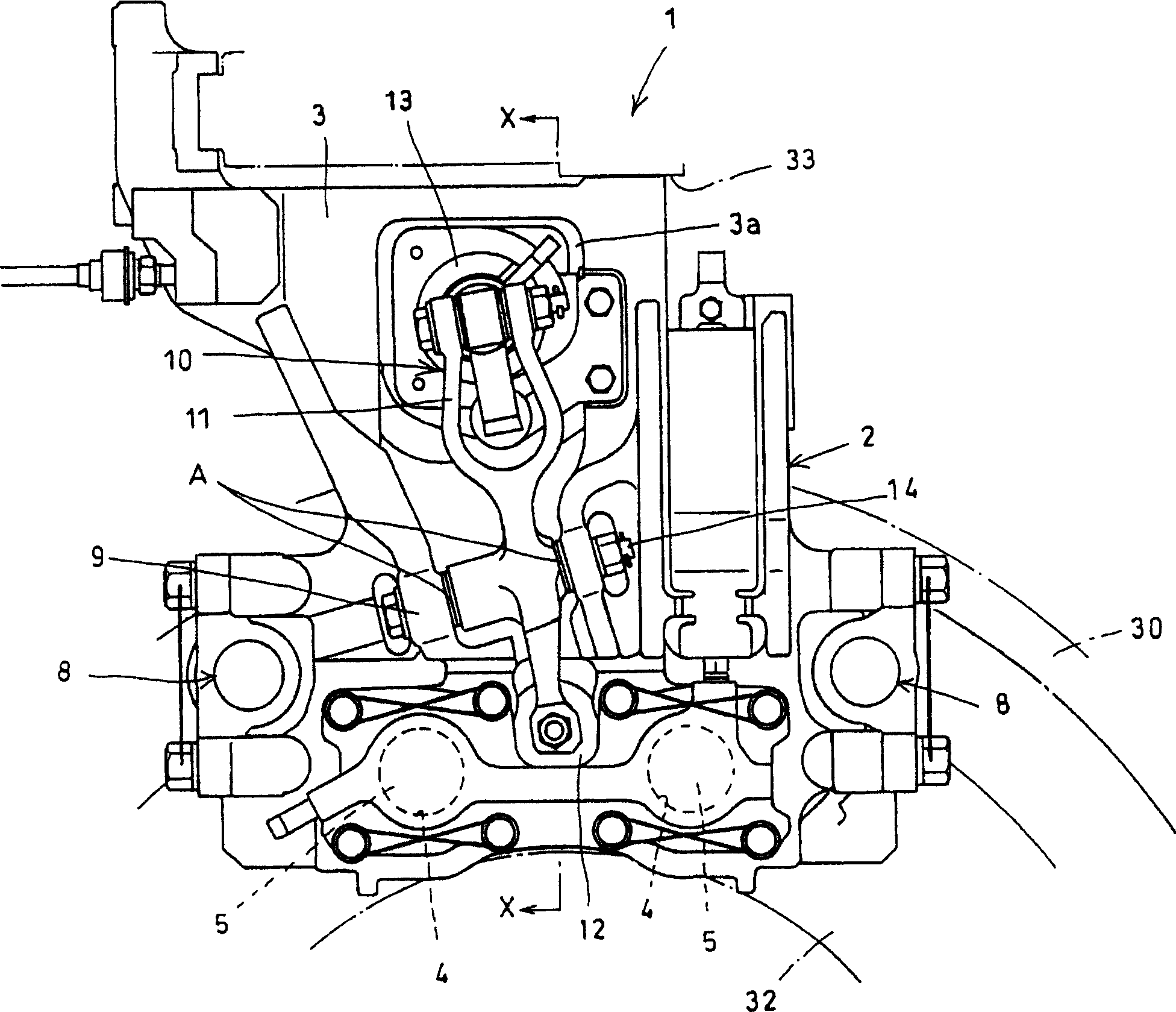

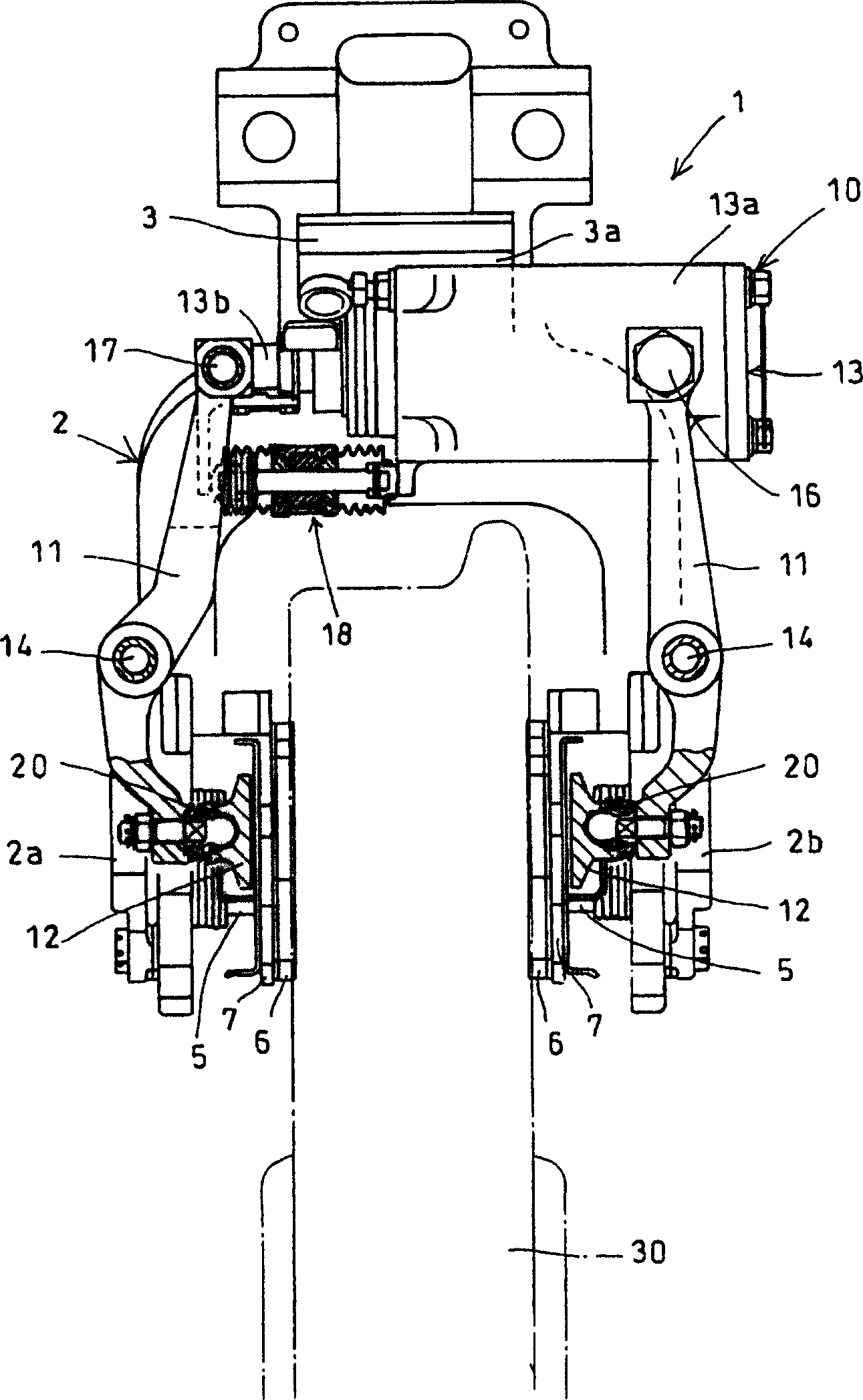

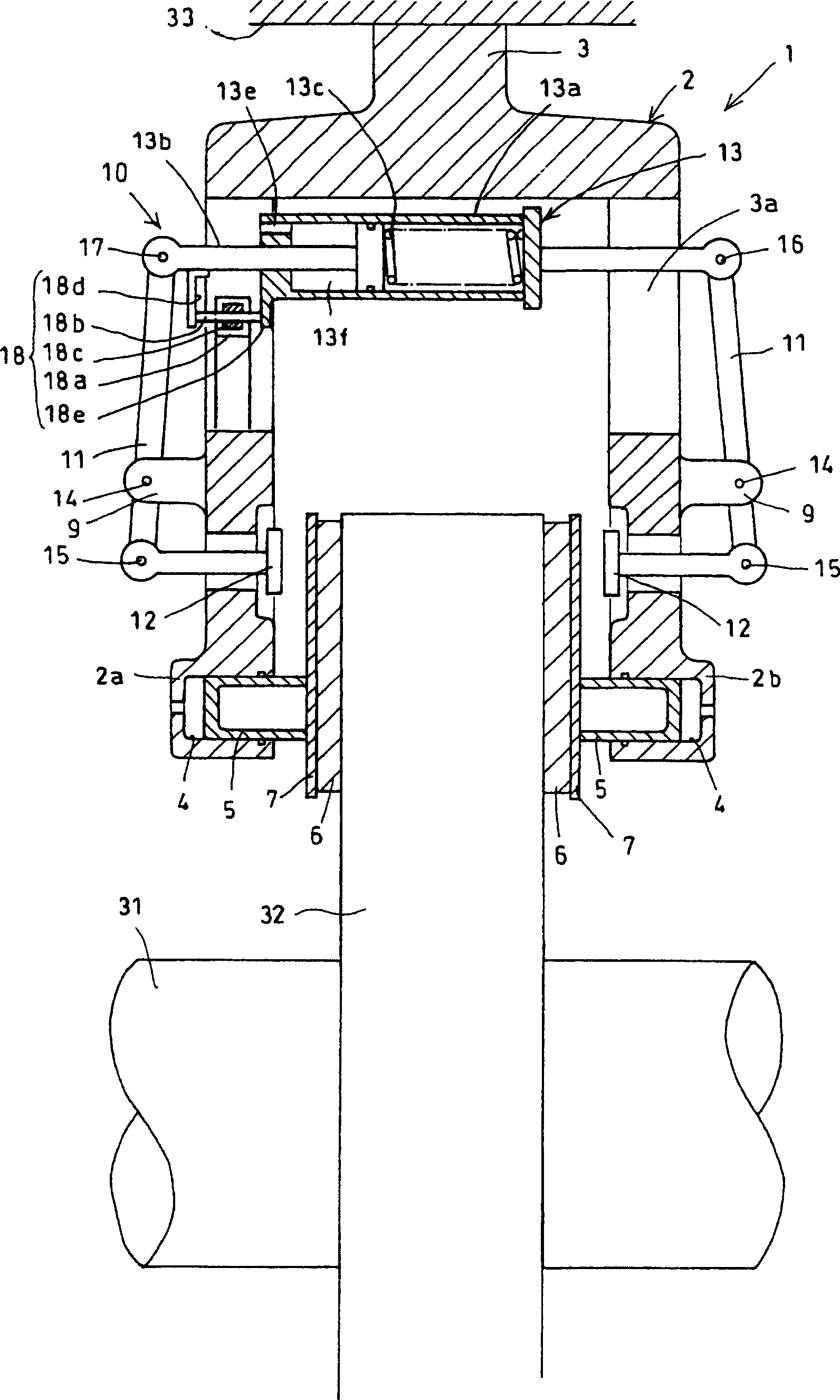

[0028] figure 1 and figure 2 An embodiment of the brake caliper device of the present invention is shown. image 3 It is a pattern diagram for easy understanding of the structure. These figures show an example in which the present invention is applied to a piston opposing type caliper device.

[0029] The caliper body 2 of the relative piston type brake caliper device 1 is installed across the figure 1 , figure 2 Wheels 30 and image 3 The disc 32 on the axle 31 is mounted on a mounting surface 33 forming part of a railway vehicle trolley.

[0030] The caliper body 2 has: a support portion 3 mounted on the mounting surface 33; a cylinder 4 provided on the left and right pliers 2a, 2b in opposite directions; and a piston 5 inserted into each cylinder 4 to be hydraulically actuated. In addition, the caliper body 2 has a sliding mechanism on the rotating-in side and the rotating-out side of the disc 32 to freely support the brake block 6 and the heat insulating gasket 7 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com