Antenna mounting structure

An antenna device and mounting bolt technology, applied in directions such as antennas, antenna supports/mounting devices, antenna parts, etc., can solve the problems of reduced operability, difficulty in aligning the nut 30 and the axis of the mounting bolts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

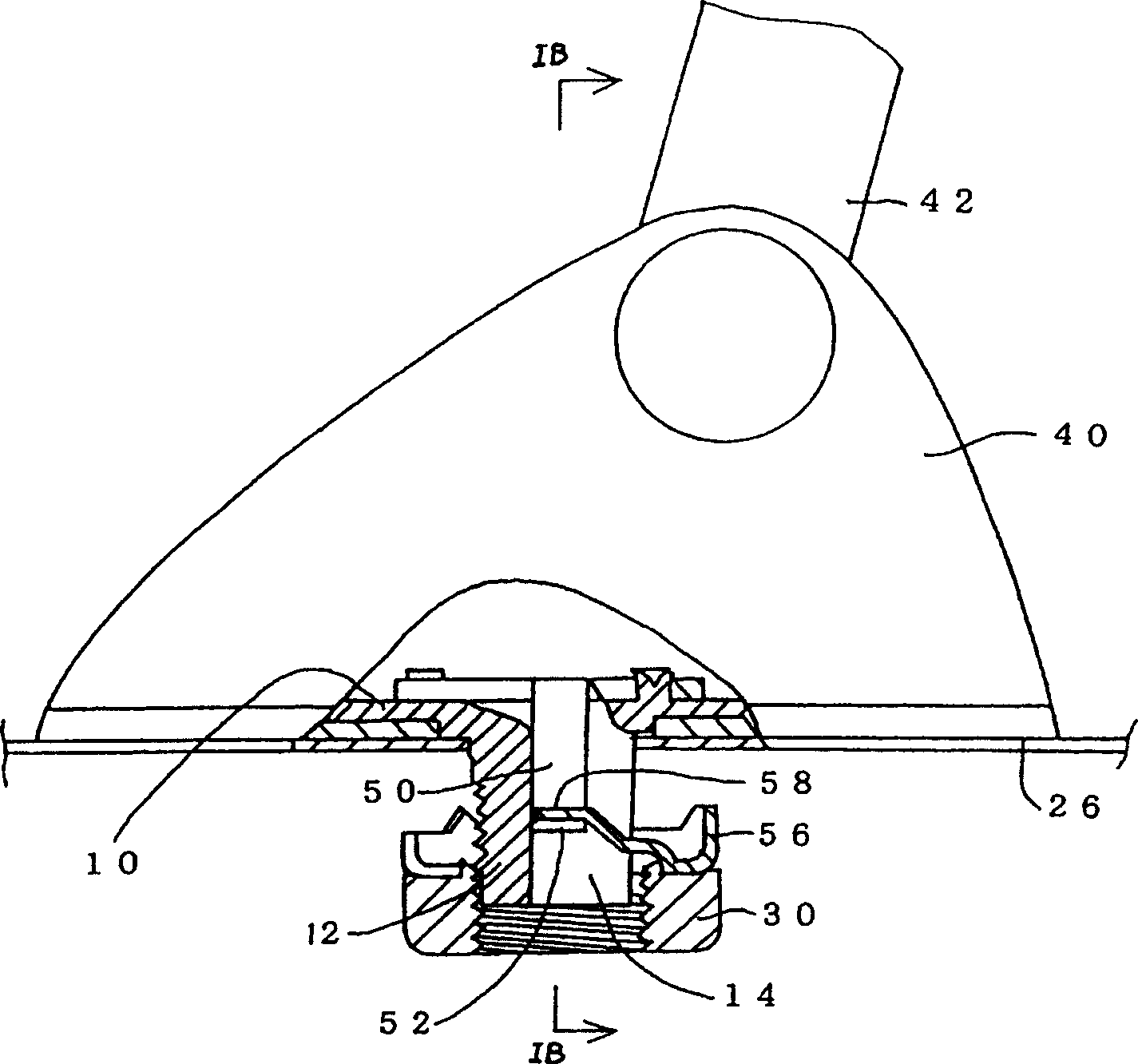

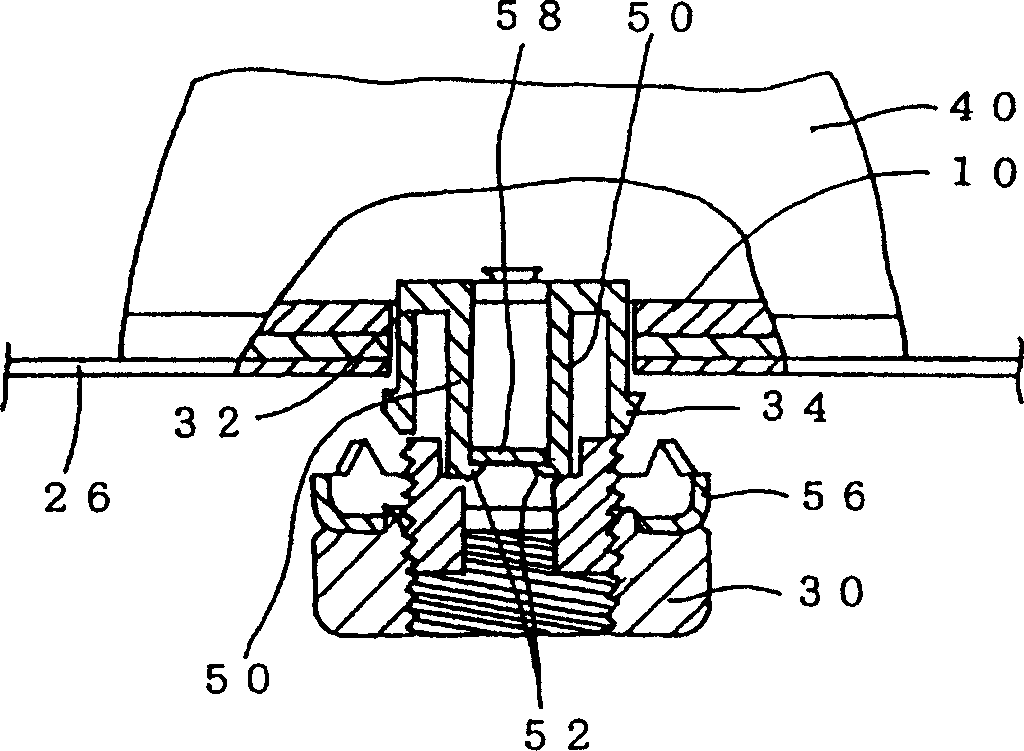

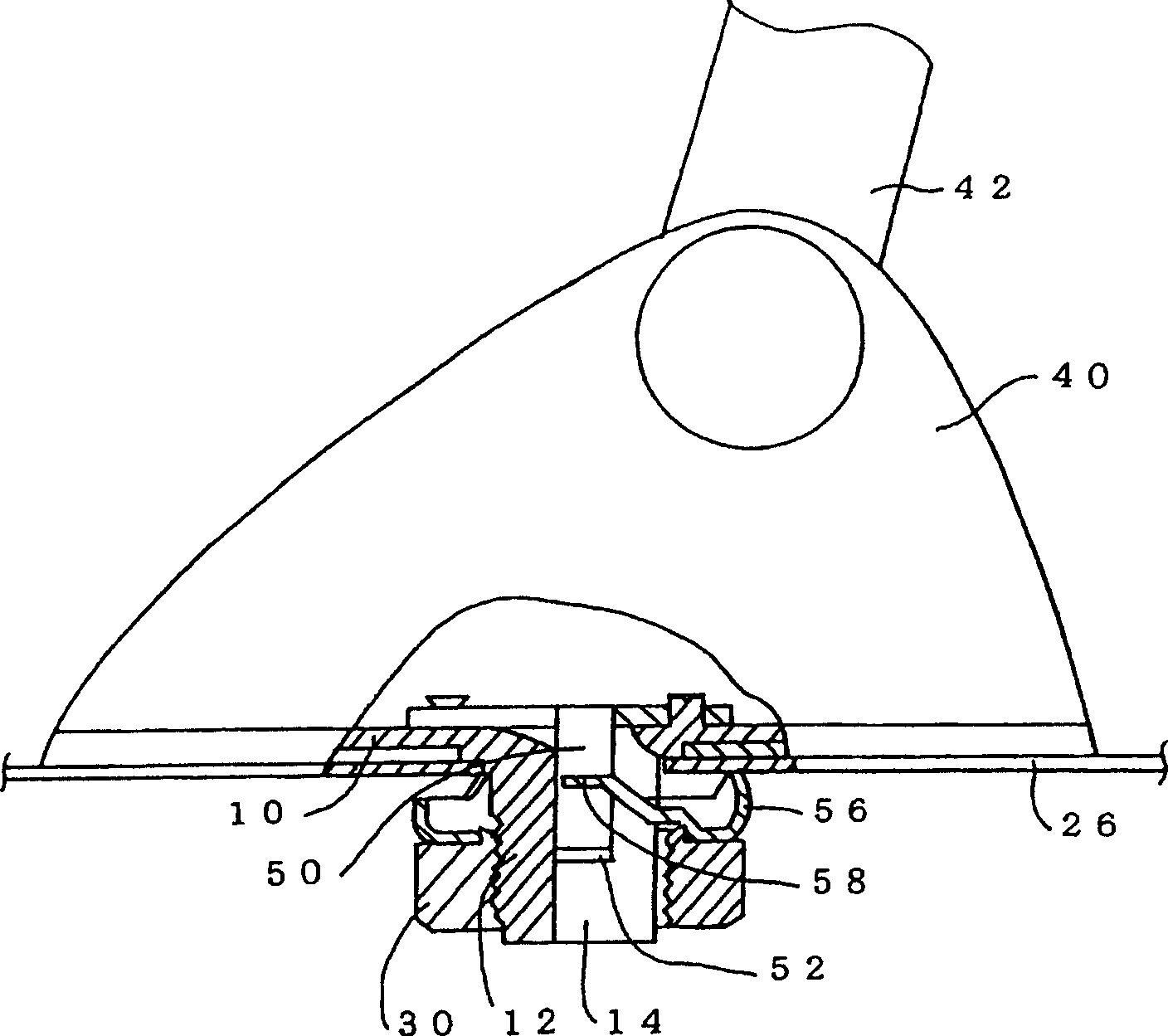

[0044] Preferred embodiments of the present invention are described in detail below with reference to the accompanying drawings. Figure 1A to Figure 6B neutralize Figure 7A to Figure 9B Similar components are denoted by the same reference numerals, and repeated descriptions thereof will be omitted.

[0045] In this example, if Figure 3A to Figure 3C As shown, the engagement arm 50 is integrally molded with the bracket 32 by a resin material having elasticity. A hook 52 is formed at a tip portion of each engaging arm 50 so that the hook is directed inward.

[0046] Such as Figure 4B with Figure 4C As shown, mounting bolt 12 forms slot 14 and recess 60 that allows engagement arm 50 to move outwardly across the width of slot 14 . In addition, if Figure 4A with Figure 4C As shown, the antenna base forms recesses on both sides of the mounting bolt 12 to allow the support arm 35 to move outward, thus forming through holes 62 on both sides of the slit 14 on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com