Liquid level tracking type multi-point temperature measuring device and manufacturing method thereof

A multi-point temperature and measuring device technology, applied in measuring devices, thermometers, measuring heat, etc., can solve problems such as affecting the pressure and sealing of pressure vessels, fluid interference around measuring points, and the inability of temperature measuring devices to track liquid level changes. To reduce the impact of pressure and sealing, reduce the effect of opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

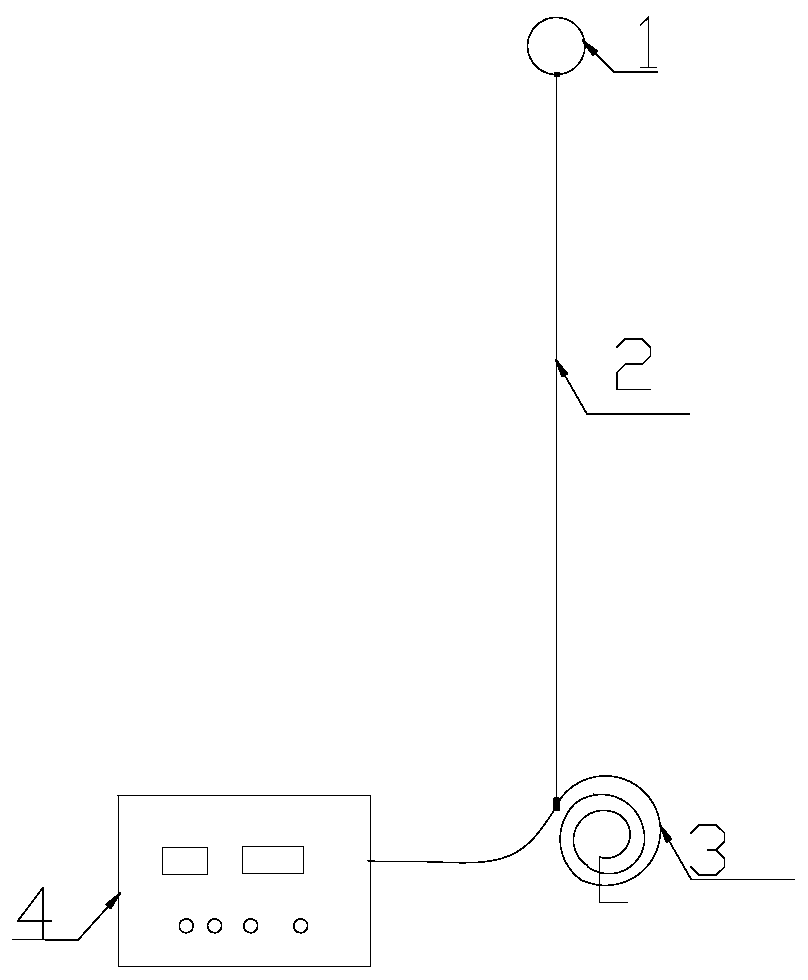

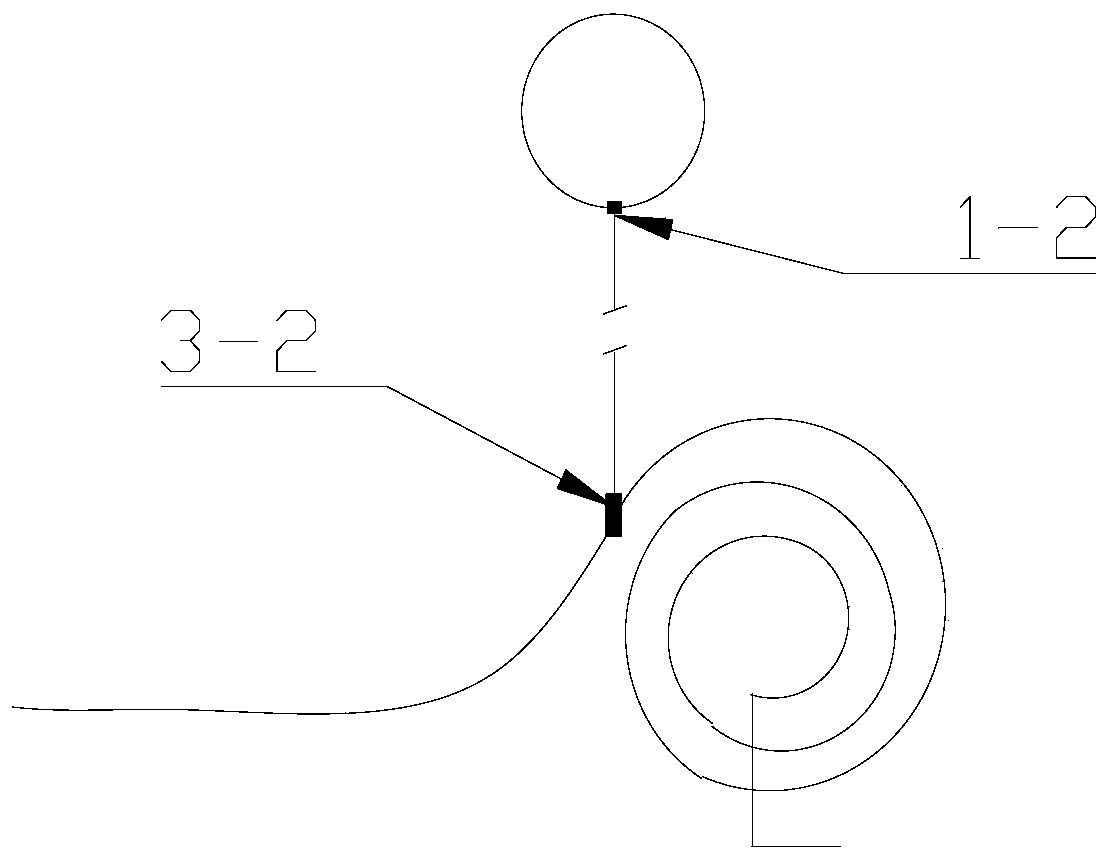

[0037] Such as Figure 1 to Figure 3 The liquid level tracking multi-point temperature measuring device shown includes an optical fiber temperature measuring line 2, and the two ends of the optical fiber temperature measuring line 2 are respectively connected to the liquid surface floating device 1 and the elastic spring 3; when the measuring device is in the liquid, The liquid surface floating device 1 floats on the liquid surface, the elastic spring 3 sinks into the liquid, and the optical fiber temperature measuring line 2 is straightened.

[0038] In this embodiment, the liquid surface floating device 1 will always float on the liquid surface, so when the liquid level changes, the liquid surface floating device 1 drives the optical fiber temperature measuring line 2 and the elastic spring 3 to rise and fall with the change of the liquid level, realizing The effect of always tracking the height of the liquid level makes the depth of each measuring point on the optical fiber...

Embodiment 2

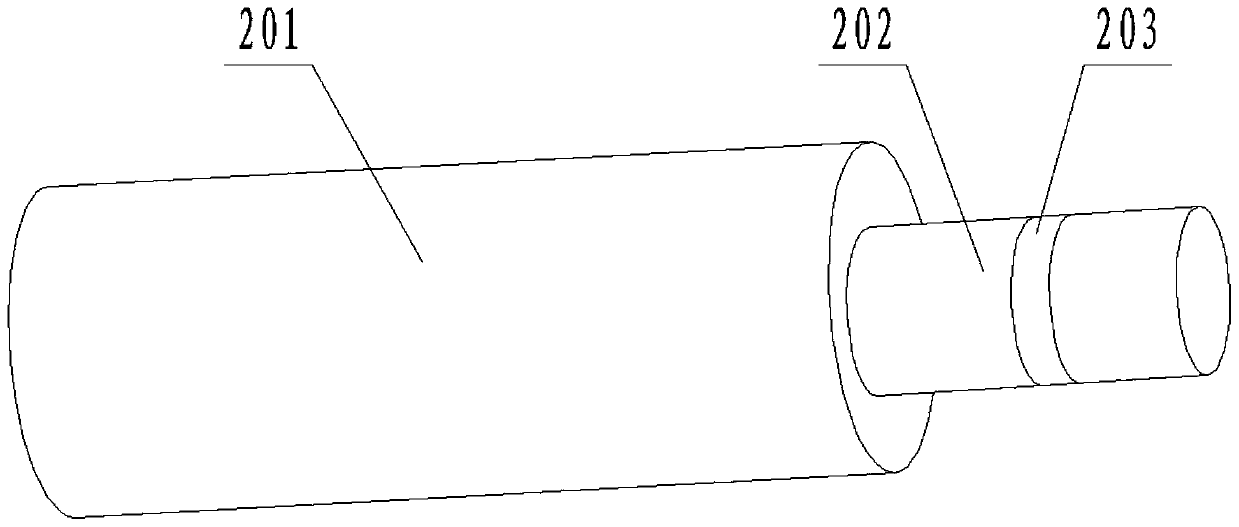

[0040] Such as Figure 1 to Figure 3 The liquid level tracking multi-point temperature measuring device shown includes an optical fiber temperature measuring line 2, and the two ends of the optical fiber temperature measuring line 2 are respectively connected to the liquid surface floating device 1 and the elastic spring 3; when the measuring device is in the liquid, The liquid surface floating device 1 floats on the liquid surface, the elastic spring 3 sinks into the liquid, and the optical fiber temperature measuring line 2 is straightened. The optical fiber temperature measuring line 2 includes a temperature measuring optical fiber 202, a grating 203, and a protective sleeve 201, the grating 203 is etched on the temperature measuring point on the temperature measuring optical fiber 202, and the protective sleeve 201 is coated on the temperature measuring optical fiber 202 outside. The protective sleeve 201 is made of metal. The wall thickness of the protective sleeve 201 ...

Embodiment 3

[0042] Such as Figure 1 to Figure 3 The liquid level tracking multi-point temperature measuring device shown includes an optical fiber temperature measuring line 2, and the two ends of the optical fiber temperature measuring line 2 are respectively connected to the liquid surface floating device 1 and the elastic spring 3; when the measuring device is in the liquid, The liquid surface floating device 1 floats on the liquid surface, the elastic spring 3 sinks into the liquid, and the optical fiber temperature measuring line 2 is straightened. The elastic clockwork 3 is a constant force spring spring, and the stretching length of the constant force spring spring is greater than the length of the optical fiber temperature measuring line 2 . The end of the optical fiber temperature measuring line 2 close to the spring 3 is also connected to the input end of the signal processor 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com