A detachable quenching tank built-in combined shroud

A shroud and quenching tank technology, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problems of unadjustable outlet height of flow restrictor, low applicability of workpiece shape, small water inlet area, etc. Low cost, good applicability, and the effect of improving quenching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

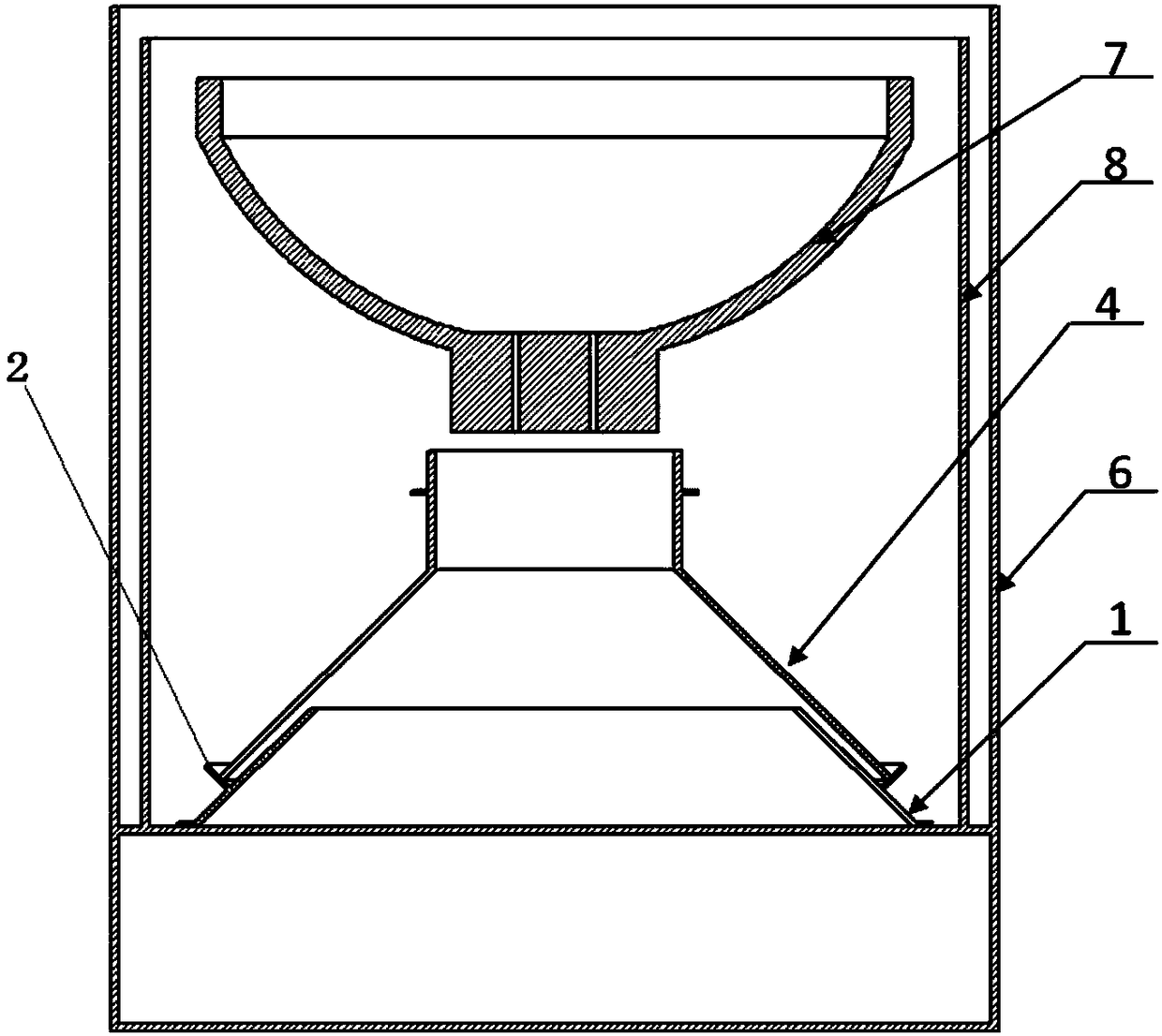

[0038] Such as figure 1 As shown, this embodiment includes: a quenching tank 6, a quenching inner tank 8, a conical base 1, and a single cone segment shroud assembly 4, such as Figure 4 As shown, the single cone segment shroud assembly 4 includes a cone segment 41 and a vertical outlet segment 42 arranged sequentially from bottom to top. The bottom diameter and taper of the cone segment 41 are adapted to the conical base 1, and the vertical outlet The shape and size of the section 42 are adapted to the workpiece to be quenched. The conical base 1 is fixed on the lower part of the quenching tank 6, and the conical surface forms a certain angle with the horizontal plane, which can reduce the loss of flow and speed caused by the horizontal deflector structure. The single-cone segment shroud assembly 4 is placed on the conical base 1 and adopts a detachable movable connection.

[0039]The quenching tank 6 described in this embodiment has a diameter of Φ11m, a height of 11m, an ...

Embodiment 2

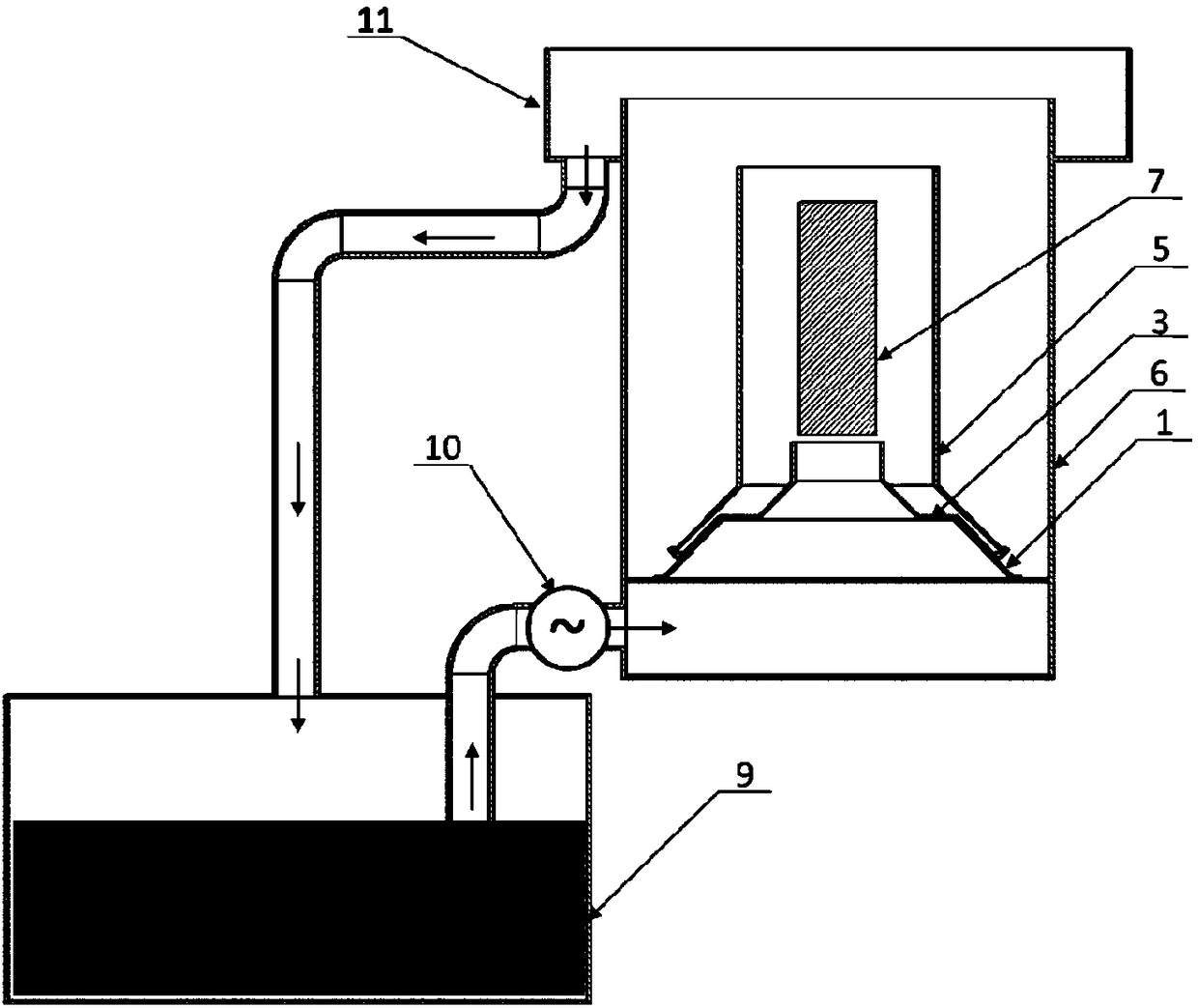

[0041] Such as figure 2 As shown, the present embodiment includes: a quenching tank 6, a conical base 1, a step-type shroud assembly 3, and a cylindrical shroud assembly 5, wherein: the conical base 1 is fixed on the bottom of the quenching tank 6, and the conical surface and The bottom surface of the quenching tank is at a certain angle, which can reduce the flow and speed loss caused by the horizontal deflector structure. The conical base 1 is connected with the quenching tank 6 by fixing bolts, which is convenient for adjustment and easy to assemble and disassemble. The stepped windshield assembly 3 and the cylindrical windshield assembly 5 are placed on the conical base 1 and are connected in a detachable manner.

[0042] In this embodiment, the quenching tank 6 has a diameter of Φ8m and a height of 10m. The quenching workpiece 7 is a long-axis workpiece with a diameter of Φ1.4m and a height of 6m. In this embodiment, a detachable quenching tank built-in combined shroud...

Embodiment 3

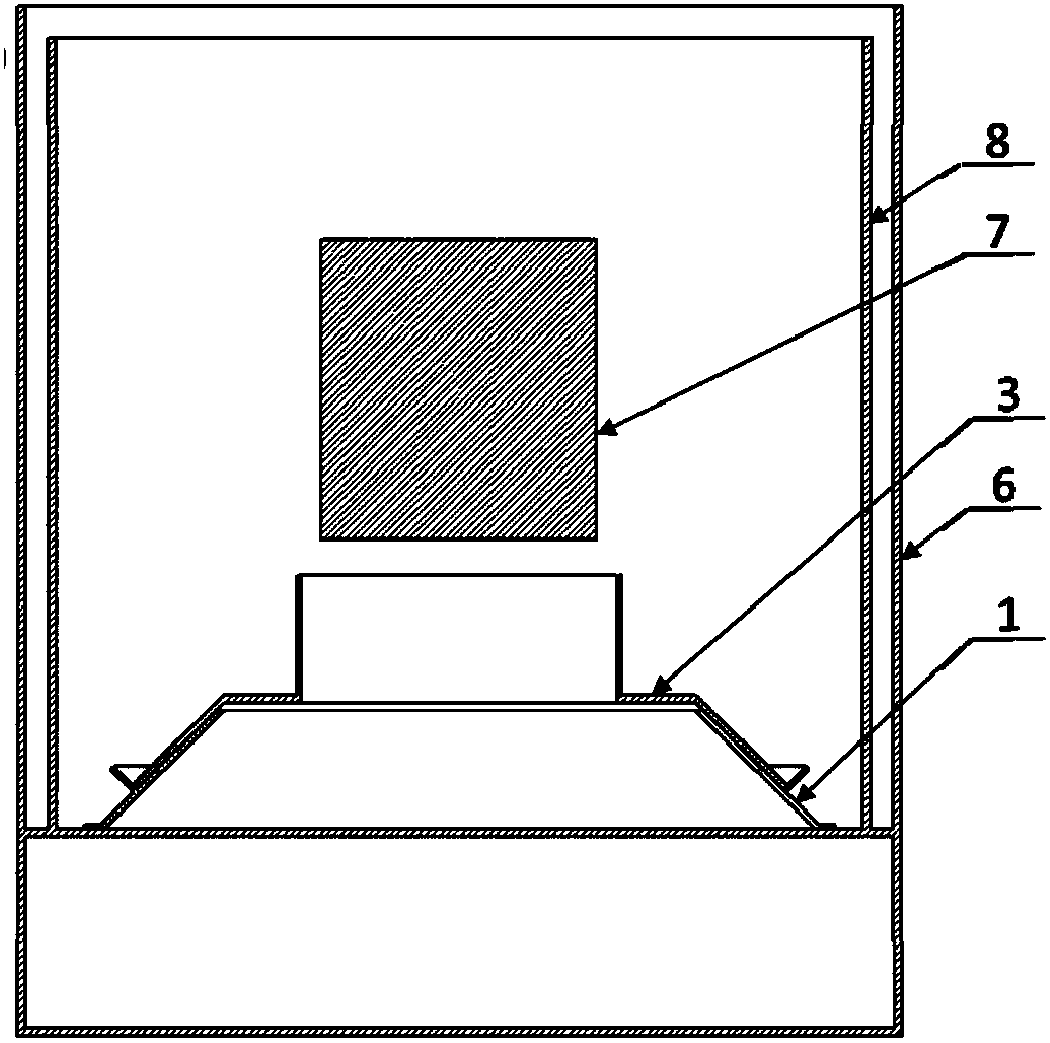

[0047] Such as image 3 As shown, this embodiment includes: a quenching tank 6, a conical base 1, and a stepped shroud assembly 3, wherein: the conical base 1 is fixed on the bottom of the quenching tank 6, and the conical surface forms a certain angle with the bottom surface of the quenching tank, which can reduce the Flow and velocity losses due to small horizontally placed deflector structures. The conical base 1 is connected with the quenching tank 6 by fixing bolts, which is convenient for adjustment and easy to assemble and disassemble. The step-type shroud assembly 3 is placed on the conical base 1 and adopts a detachable movable connection.

[0048] The quenching tank 6 described in this embodiment has a diameter of Φ11 m and a height of 8 m, and 12 bottom inserted propellers are installed at the bottom to make the water in the quenching tank flow. The quenching workpiece 8 is a square workpiece, and its size is 3.5m×3.5m×3.5m. A stepped wind deflector assembly 3 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com