Nail gun

A nail gun and nail technology, applied in the field of nail guns, can solve the problem that various pressure ranges cannot be effectively used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

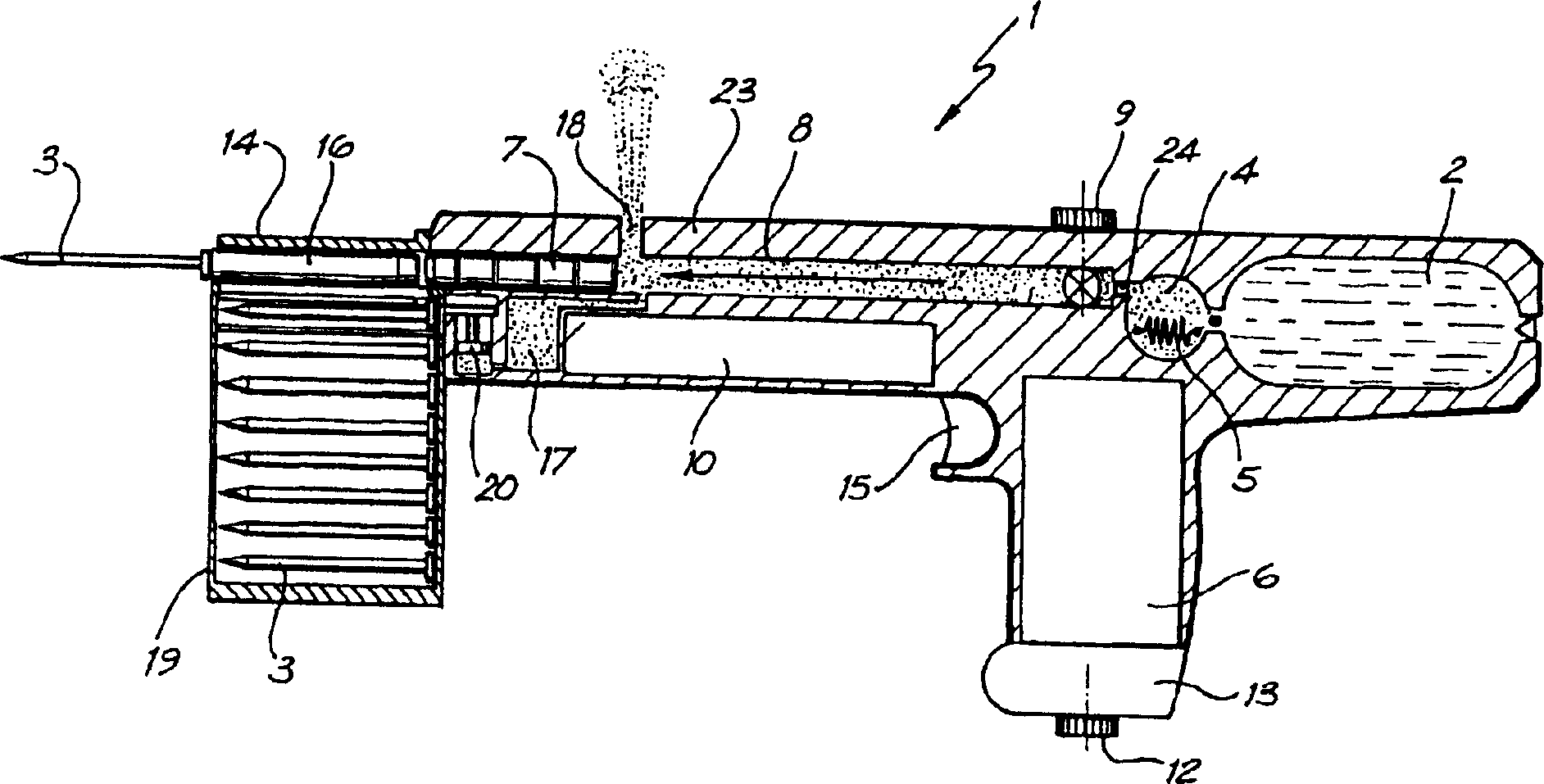

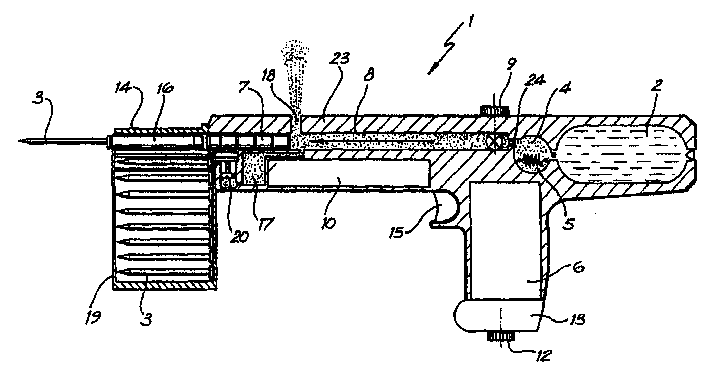

[0017] figure 1 A nail gun 1 according to an embodiment of the present invention has been described. The nail gun 1 is a hand-held tool used in woodworking and construction.

[0018] The nail gun 1 includes a 250cc liquid carbon dioxide (CO 2 ) reservoir 2, the liquid carbon dioxide is transformed into "supercritical fluid" or "high concentration gas" as an explosive energy source by phase transition to push out or shoot out the nail 3. The nail gun 1 includes a high-pressure chamber 4, liquid CO 2 A phase change occurs in it and it is transformed into a high-concentration gas. The high pressure chamber is in fluid communication with a barrel 23 via a gas shutoff valve 24 . The CO is heated by a heating element 5 powered by a battery pack 6 similar in size and shape to a conventional cordless drill battery pack. 2 heating. In this embodiment, the piston slider 7 located in the bore 8 moves the CO through the plunger 16 2 The burst can be mechanically transmitted to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com