Device and method for drawing out sheets

A technology for taking out devices and sheets, which is applied in the directions of transportation and packaging, separation of objects, static electricity, etc., and can solve problems such as not being able to take out one sheet at a time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

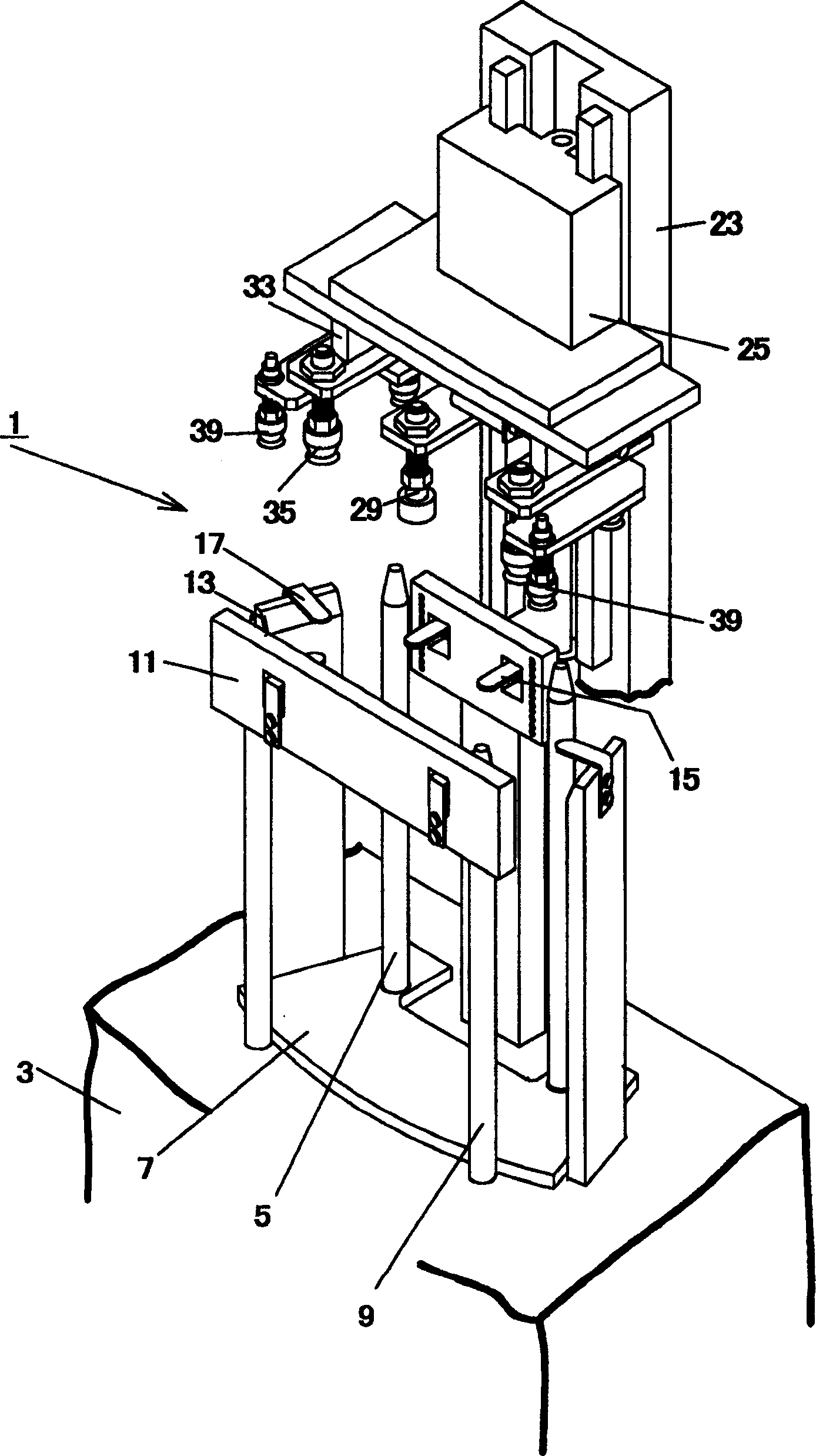

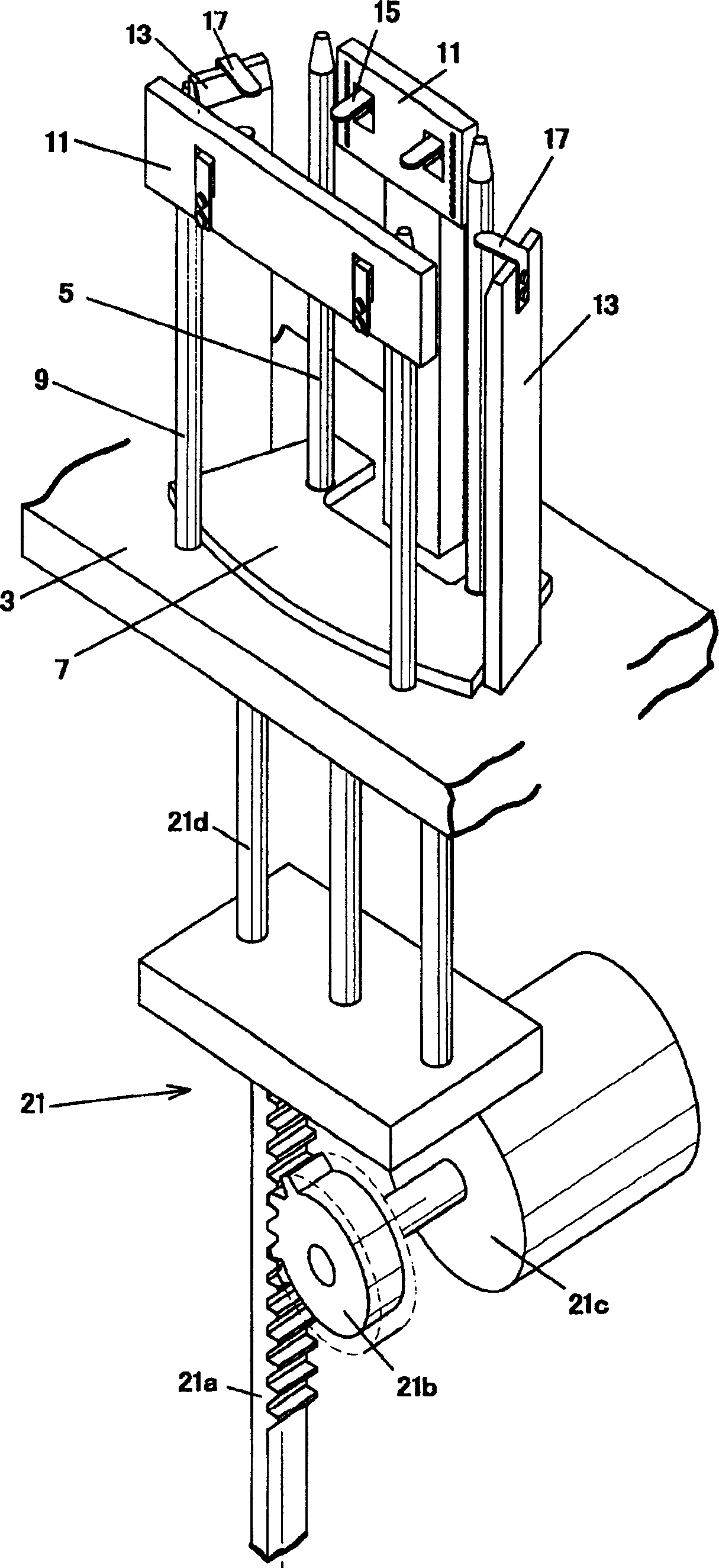

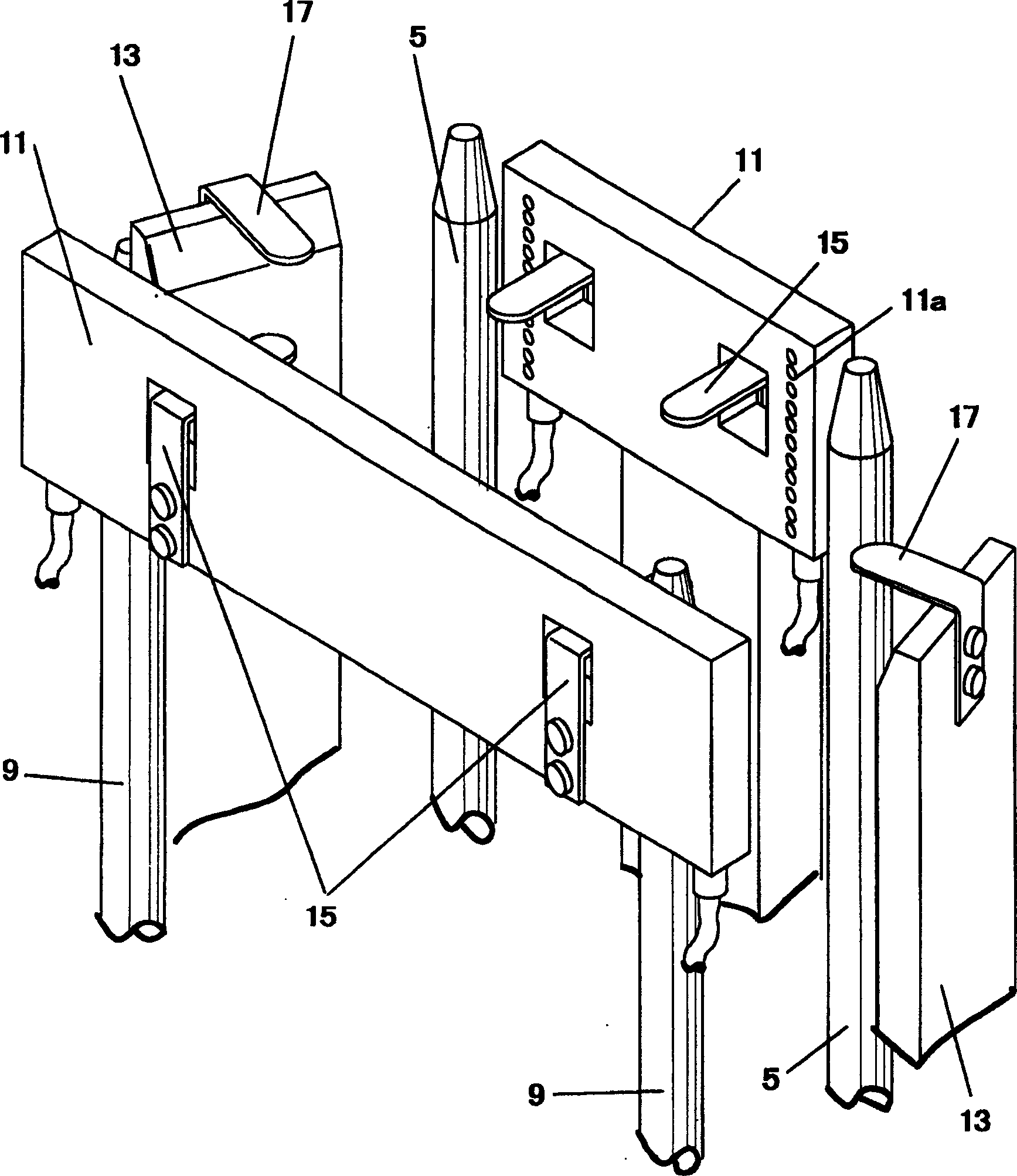

[0019] Embodiments of the present invention will be described below with reference to the drawings.

[0020] exist Figure 1 to Figure 4 Among them, the sheet take-out device 1 takes out one sheet at a time from the sheet group 19 in which a plurality of sheets 19a are stacked when the sheet 19a is installed in, for example, a mold (not shown) of an insert molding machine. The device for sequentially taking out the uppermost sheet 19a has five guide posts 5 provided at predetermined intervals on the main body 3, and the guide posts have an axis in the vertical direction and have a predetermined axis length. Each guide post 5 is supported by a support plate 7 as a support member that can move up and down. And the front (front side) and the rear (back side) of this bearing plate 7 are respectively provided with mounting shafts 9, and both sides are respectively erected with upper and lower frames 13, and the top of the mounting shafts 9 is fixed with a front and rear pair of mo...

Embodiment 2

[0039] In this embodiment, an ion generator (not shown) is connected to an air supply device (not shown) that injects air from the air injection holes 11a provided on each mounting plate 11, and the injected air becomes charged ion wind. In this way, when static electricity is generated in each sheet 19a of the sheet group 19, the static electricity is neutralized and removed by the charge of the ion wind, thereby preventing the sheets 19a from being electrostatically attracted to each other.

Embodiment 3

[0041] In this embodiment, a charge generator such as a discharge device or an ion generator is provided at the holding position formed by the adsorption member 35 to charge the air around the holding position. In the case of static electricity generated on each sheet 19a in the sheet group 19, use the air with the required charge generated by the static electricity generating device to neutralize and remove the static electricity of the sheet 19a to prevent the sheets 19a from being electrostatically attracted to each other , it is possible to restrict simultaneous taking out of a plurality of sheets 19a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com