Steel reinforced concrete hollow floorslab

A technology of reinforced concrete and hollow floor slabs, which is applied in the direction of floor slabs, formwork/formwork/work frames, structural elements, etc., and can solve the problems of increased construction time and construction difficulty, large reinforced concrete modulus, high steel and concrete consumption To achieve the effect of reducing the difficulty of construction, less concrete consumption, and saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

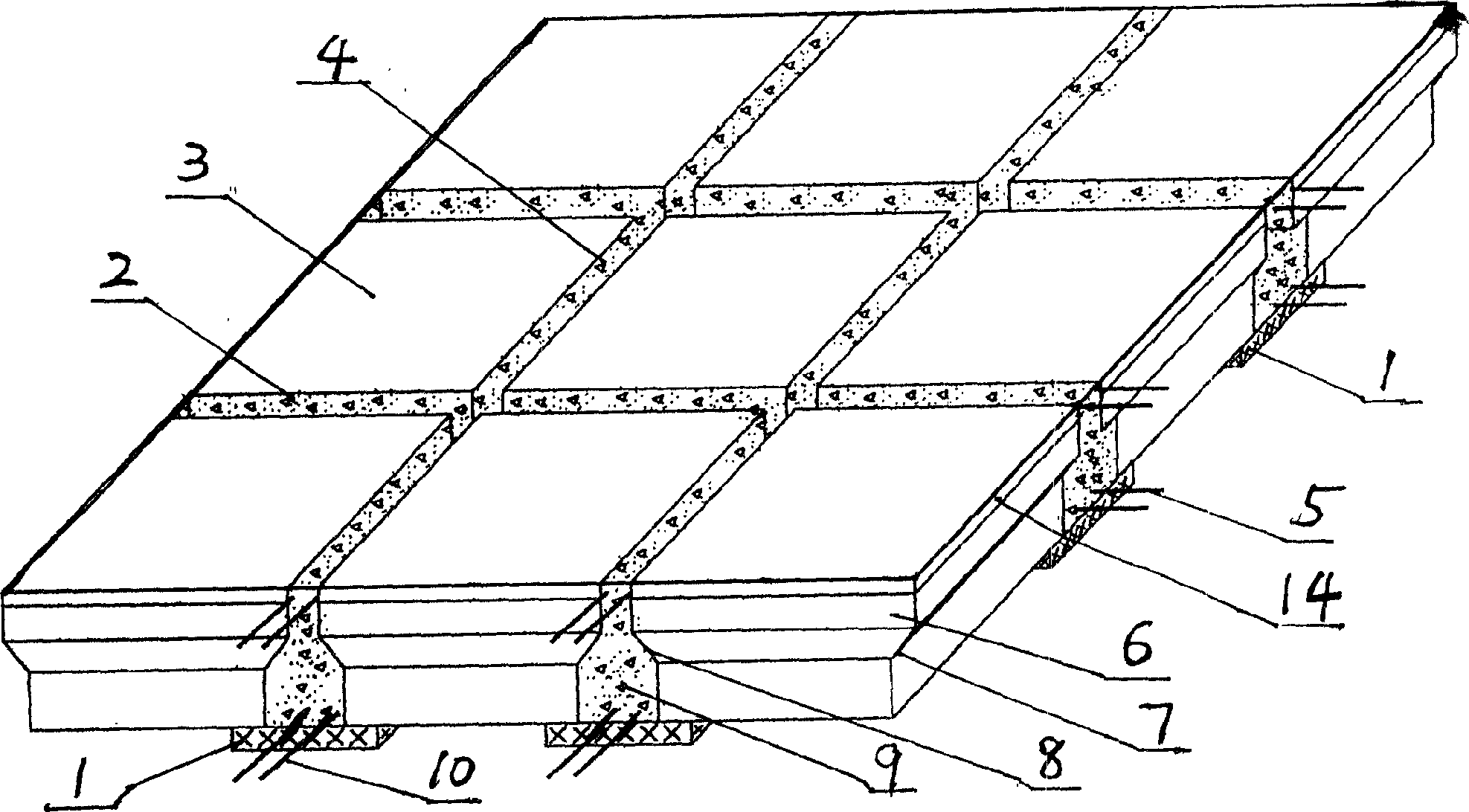

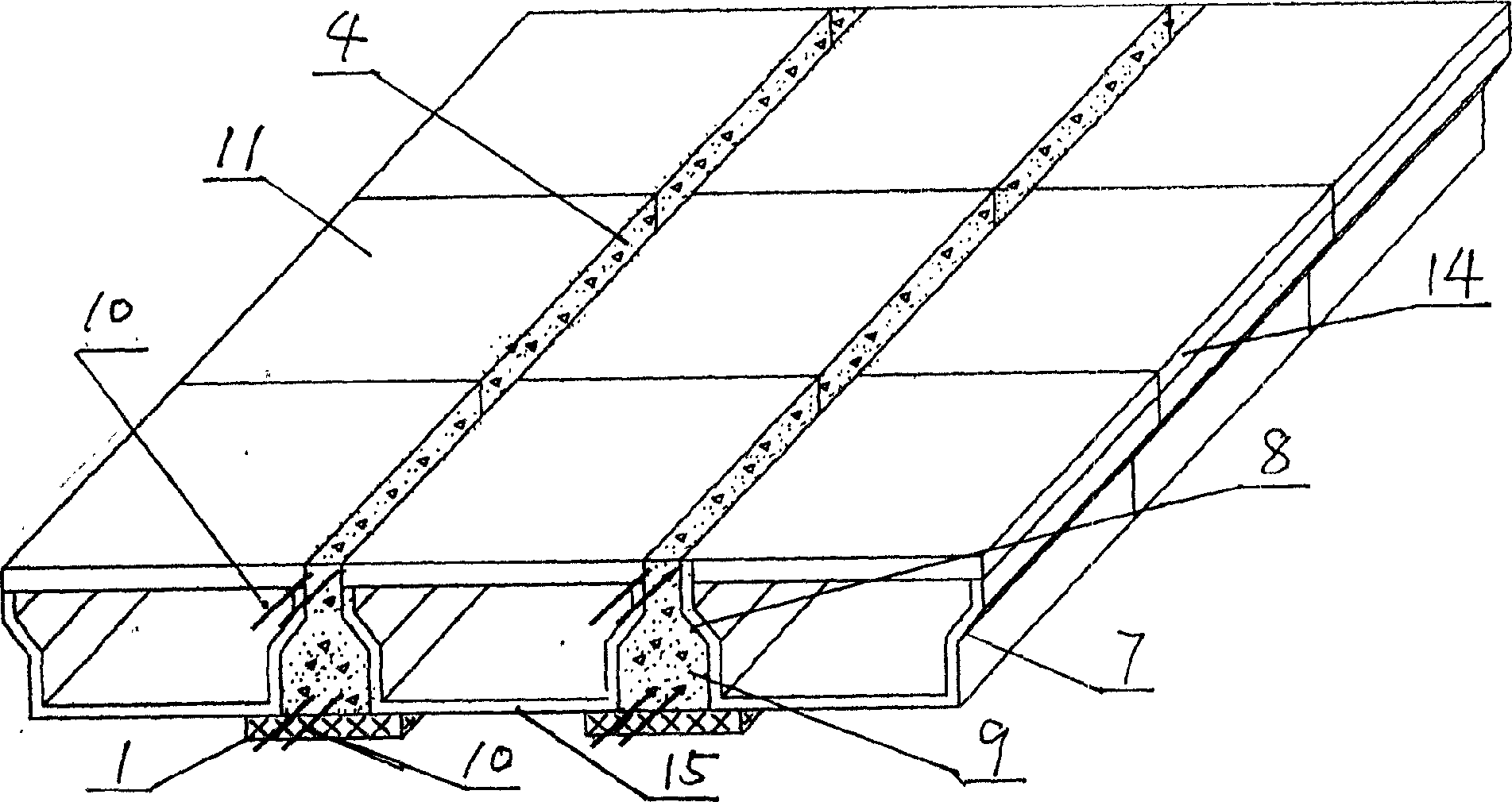

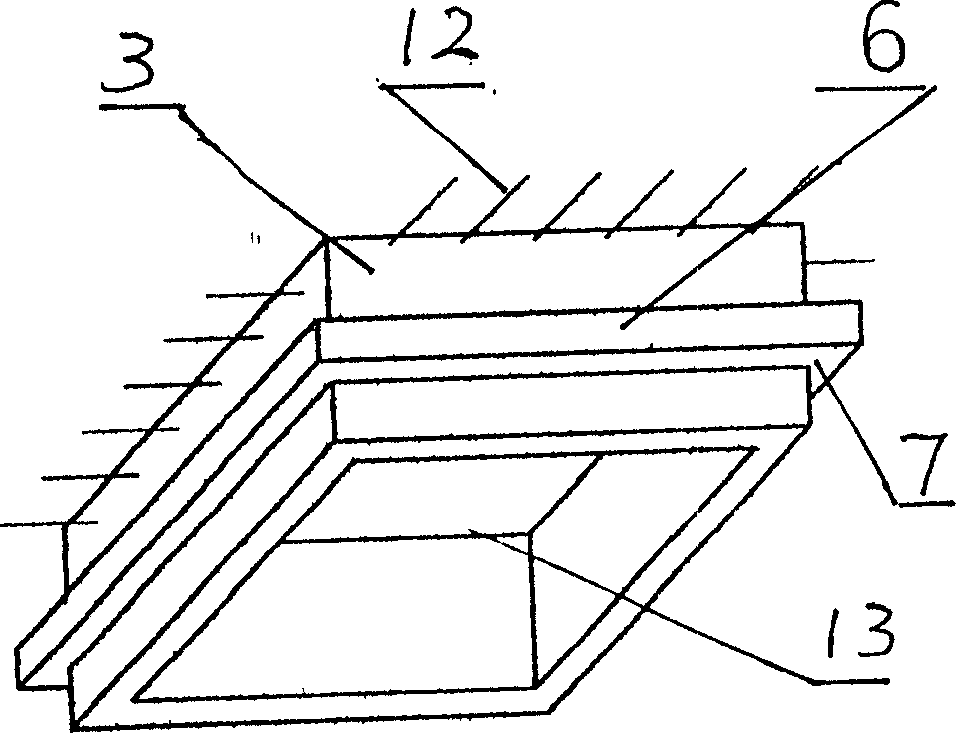

[0017] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , the reinforced concrete hollow floor slab includes reinforced concrete prefabricated components 3, 11, dense ribs 2, 4, the reinforced concrete prefabricated component 3 is a box-shaped hollow component, the reinforced concrete prefabricated component 11 is a channel-shaped hollow component, and the prefabricated component 3 11. The outer wall of 11 is provided with stress-receiving protrusions 6, and the two sides of the dense ribs 2 and 4 are provided with supporting protrusions 9 that match the force-receiving protrusions 6. On-site construction, first erect the criss-cross formwork 1, a plurality of prefabricated components 3 or 11 are vertically and horizontally arranged on the formwork 1, lay vertical and horizontal steel bars 10 and 5 at the gaps between the vertically and horizontally arranged prefabricated components 3 or 11, and pour concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com