Hanging method for communication light cable in water drainining pipeline

A technology for drainage pipes and optical cables, applied in the direction of optical fiber/cable installation, etc., to achieve safe and reliable mounting, wide application prospects, and reduce power loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

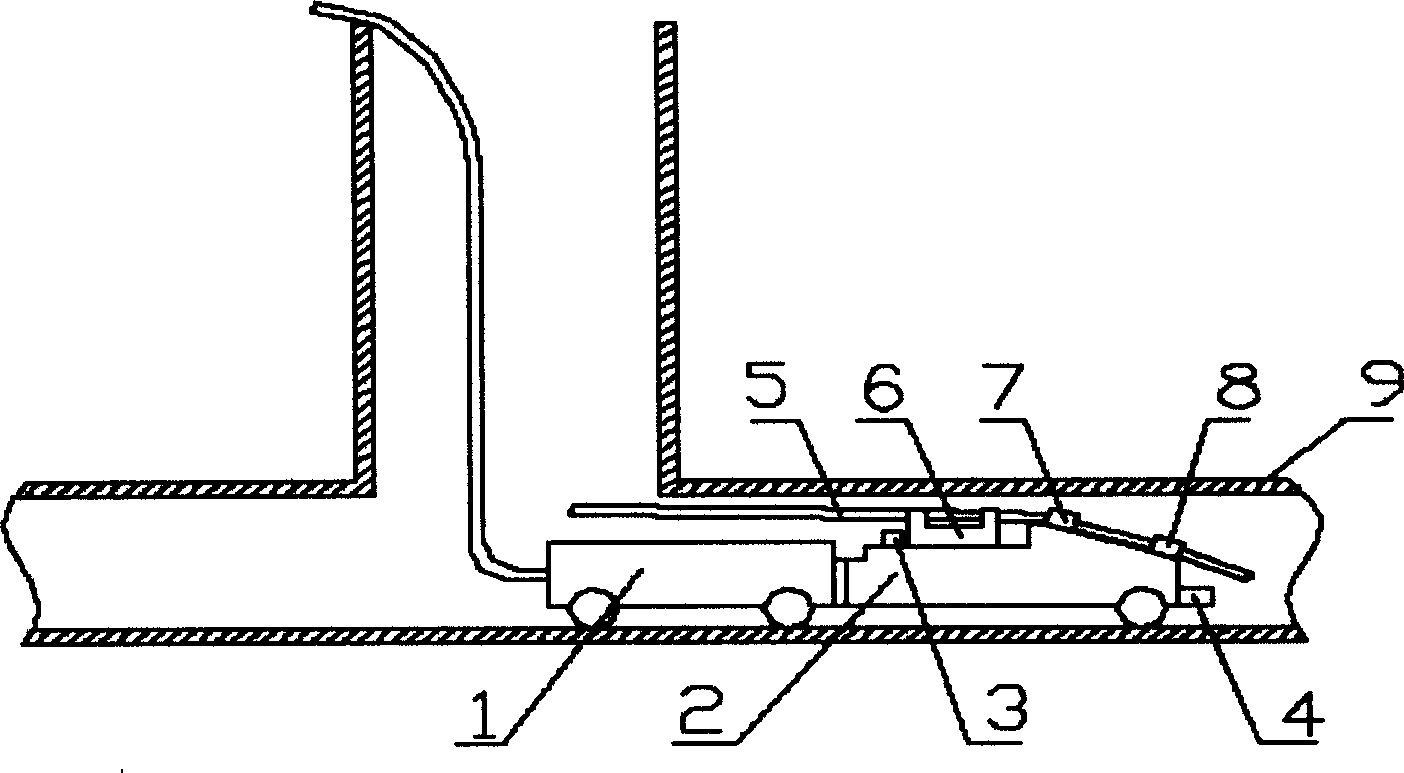

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The present invention utilizes the method for carrying out optical cable hanging by robot as figure 1 As shown, when the hanging operation starts, the main driving section 1 of the pipeline robot is first put into the drainage pipe 9, and the hanging section 2 is installed. The front section of the hanging section 2 is provided with a front end groove 8 and a rear end groove 7, the two grooves are arranged obliquely, the rear section of the hanging section 2 is provided with a top sleeve 6 driven by a motor, and the optical cable 5 is placed in the front groove 8, In the rear end groove 7 and the top sleeve 6.

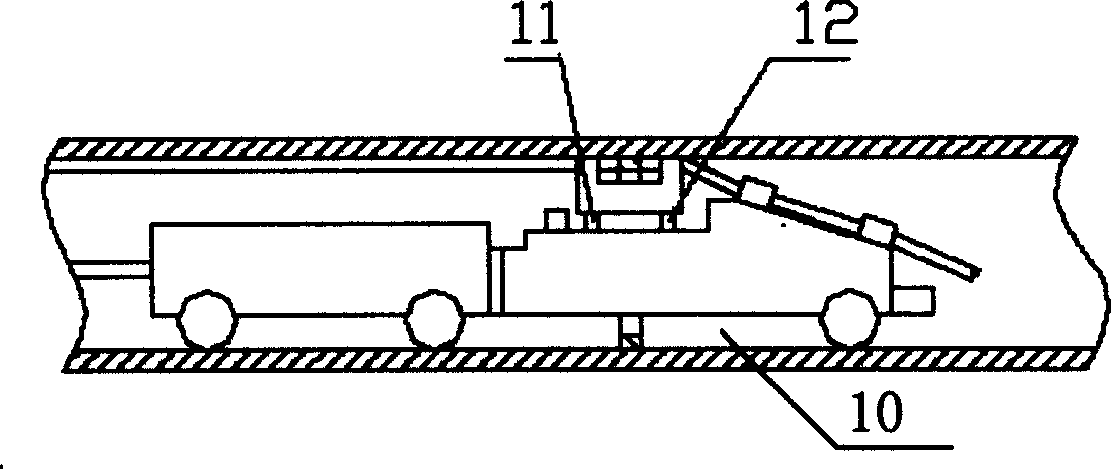

[0024] figure 2 Schematic diagram of lifting the optical cable for the top sleeve of the pipe robot and pushing the optical cable sleeve into the collar slot.

[0025] figure 2 In the middle, when the robot advances to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com