Decoupling control system of chemical of chemical multivariable production process

A production process, decoupling control technology, applied in the field of decoupling control systems, novel decoupling control systems, can solve the problems of inconvenient promotion and use, no fundamental solution to the coupling effect, and low adjustment level of the control system. Superiority and Practicality, Good Robust Stability, Effect of Advanced Control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The decoupling control system of the present invention will be further described below in conjunction with the drawings and embodiments.

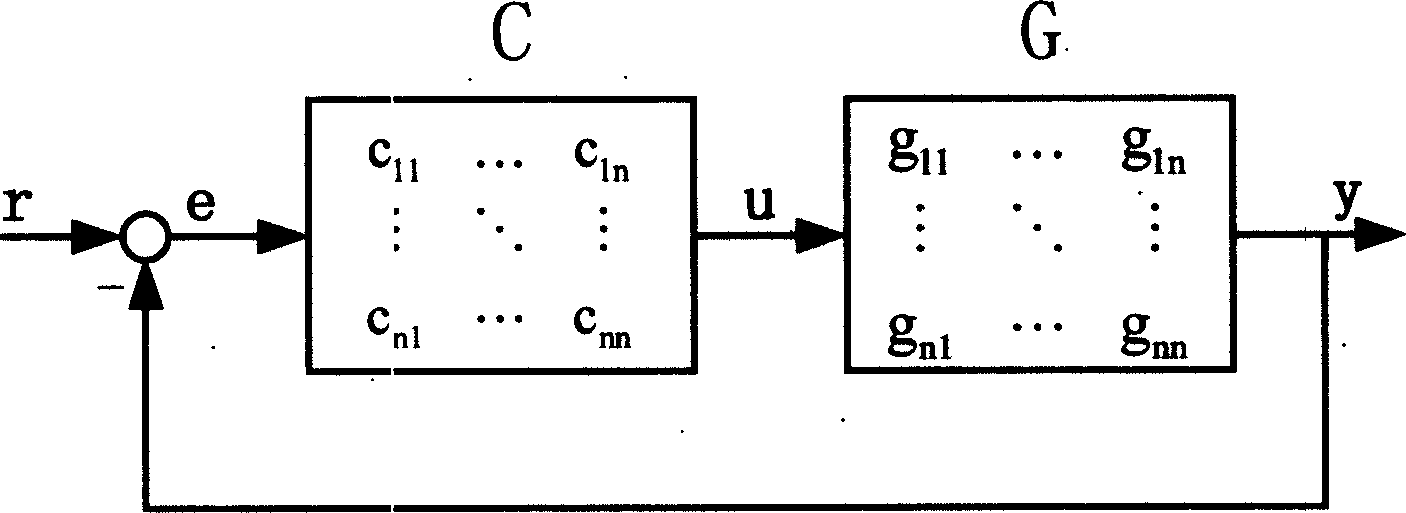

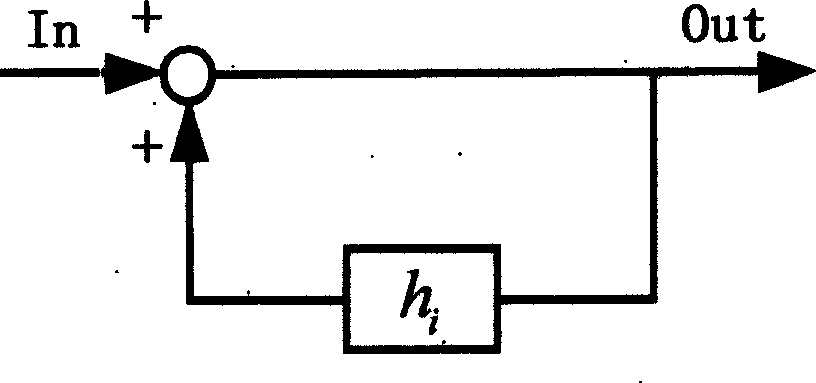

[0019] Such as figure 1 The shown decoupling control system of the present invention is composed of the following two parts: an n×n dimensional decoupling controller matrix C and a multi-channel signal mixer (circled nodes in the figure). where n is the output dimension of the controlled multivariable process, at least one controller in each column of the decoupling controller matrix C is composed of a rational linear controller connected in series with a control closed loop, and the remaining controllers are respectively It consists of a rational linear controller connected in series with a control closed loop and a time-delay compensator. The multi-channel signal mixer is arranged at the input end of the decoupling controller matrix C, and it has a set of n-dimensional positive polarity input ends, a set of n-dimensional negative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com