Fail-safe control apparatus for internal combustion engine equipped with variable valve characteristic mechanism and method thereof

A valve characteristic and fault protection technology, applied in electrical control, mechanical equipment, engine control, etc., can solve problems such as unstable combustion, insufficient air intake, and deterioration of handling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

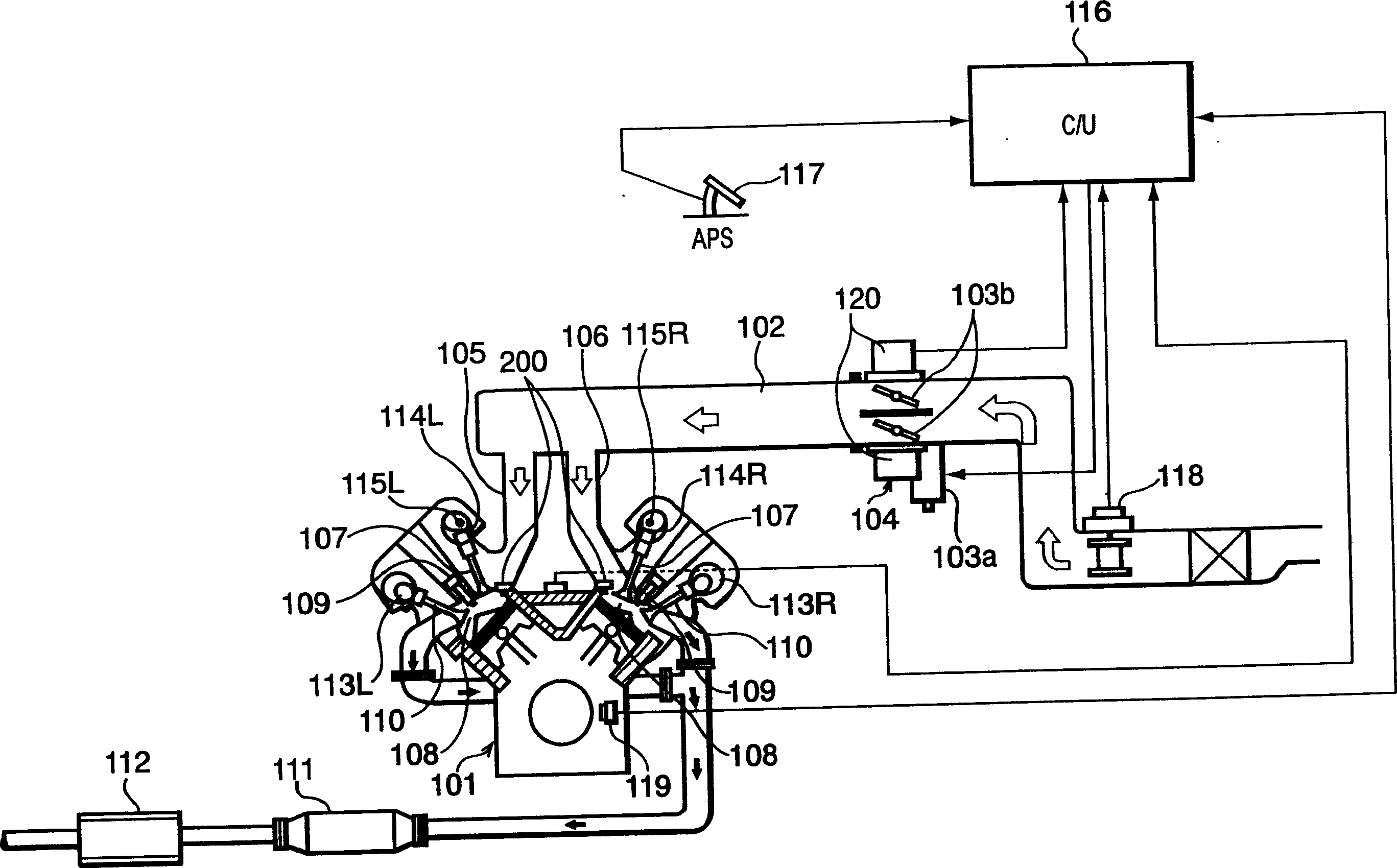

[0019] exist figure 1 Among them, in the intake pipe 102 on the upstream side of the V-shaped internal combustion engine 101 equipped with the fail-safe control device according to the present invention, an electronically controlled throttle (ETC) 104 for driving the throttle 103b is provided, and the ETC 104 passes The throttle motor 103a is turned on and off.

[0020] Intake manifolds 105 and 106 branched from the intake pipe 102 are respectively connected to the cylinder banks on the left and right side bodies formed in a V shape. Then, the air that has passed through the ETC 104 and the intake manifolds 105 and 106 is drawn into each combustion chamber 108 through the intake valve 107 of each cylinder. A spark plug 109 is mounted on each combustion chamber 108 . Furthermore, a fuel injection valve 200 is provided for each cylinder.

[0021] Combusted exhaust gas is exhausted from each combustion chamber 108 via each exhaust valve 110 , then purified by a catalytic conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com