Method for mfg. connectors

A manufacturing method and technology for electrical connectors, which are applied in the manufacture of contacts, the manufacture of contact boxes/bases, and the assembly/disassembly of contacts, can solve the deformation of the first mating surface 651, the recovery deformation of the bumps 7211, and the retention of Problems such as poor effect, to achieve the effect of increasing the holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

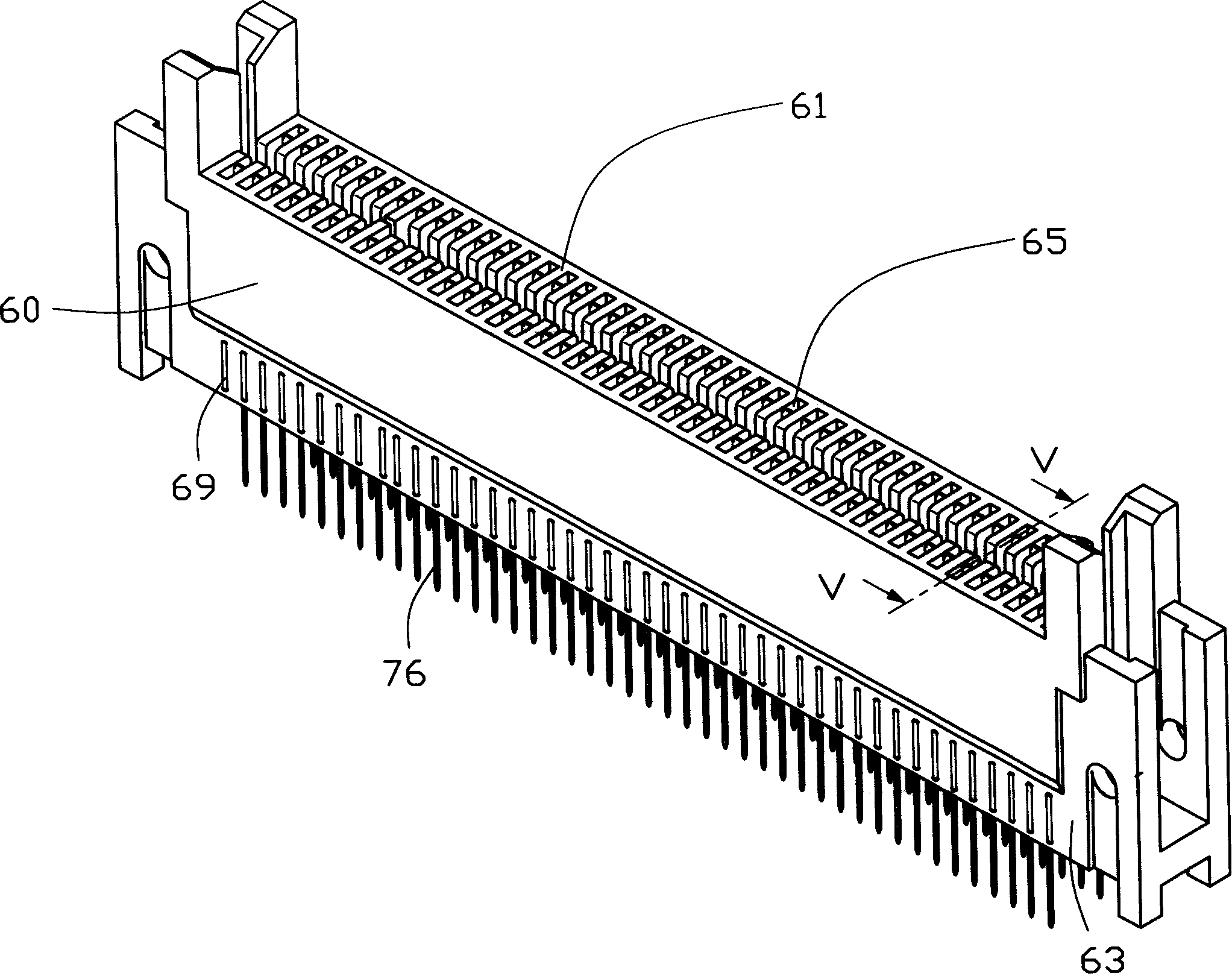

[0025] Please also refer to Figure 8~ Figure 12 The electrical connector 10 of the present invention is used to connect a sub-circuit board (not shown) to a circuit board (not shown), and includes a long and narrow insulating body 20 and a plurality of terminals 30 accommodated in the insulating body 20 .

[0026] The insulating body 20 has a mounting surface 22 for mounting on a circuit board, an inserting surface 21 opposite to the mounting surface 22 , and a first outer surface 23 perpendicular to the two surfaces. The first outer surface 23 is provided with a second outer surface 27 near the installation surface 22 for punching, and there is a concave step between the second outer surface 27 and the first outer surface 23 . The middle position of the insertion surface 21 is recessed with a groove 24 parallel to the long and narrow direction, and thus forms two side walls 26 and a bottom wall 28. On both sides of the groove 24, there is a penetrating installation surface 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com