Roller

A roller and body technology is applied in the field of rollers that carry the rotation of rotomolding molds, which can solve the problems of roller displacement, breakage, unfavorable maintenance and other problems, and achieve the effects of improving convenience, improving holding force, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

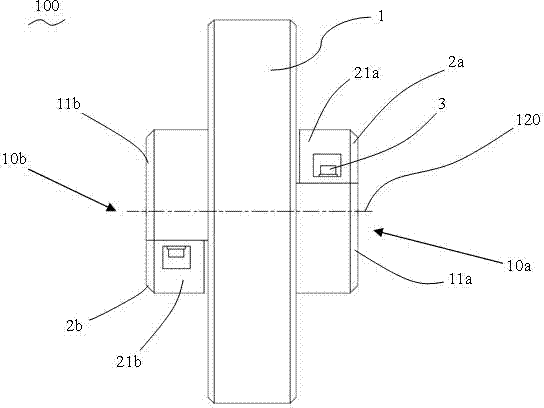

[0028] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

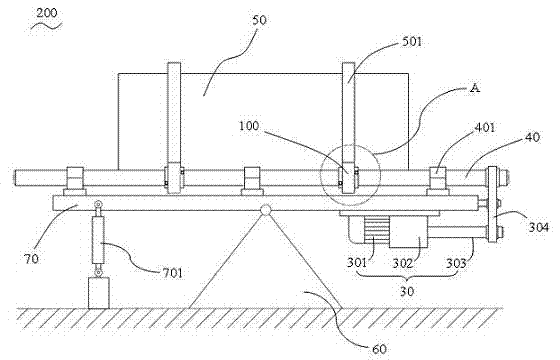

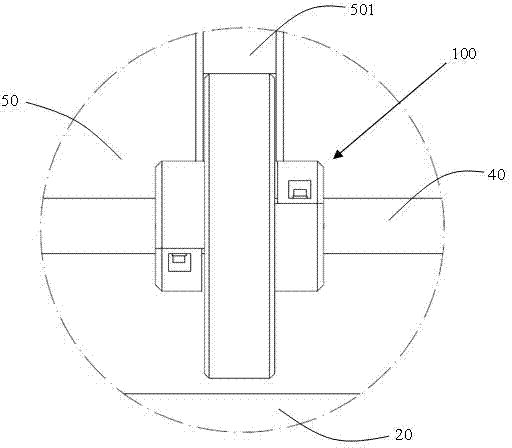

[0029] Please refer to figure 1 as shown, figure 1 A structural schematic diagram of a roller 100 applied to a rotational molding machine 200 for application of the present invention. In this embodiment, the rotational molding machine 200 includes: a support 60 arranged on the ground plane and a swing table 70 located on the top of the support 60 . The swing table 70 realizes the up and down swing of the swing table 70 through the telescopic movement of the hydraulic device 701 . Simultaneously, a drive mechanism 30 is also pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com