Rotor flight car

A rotor and car technology, applied in the field of manned aircraft and its models, can solve problems such as poor safety performance, affecting the process of aircraft entering the home, and lack of road maneuvering, so as to achieve excellent air-ground maneuverability, safety and reliability, The effect of good road maneuvering and take-off and landing capabilities, and good road maneuvering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

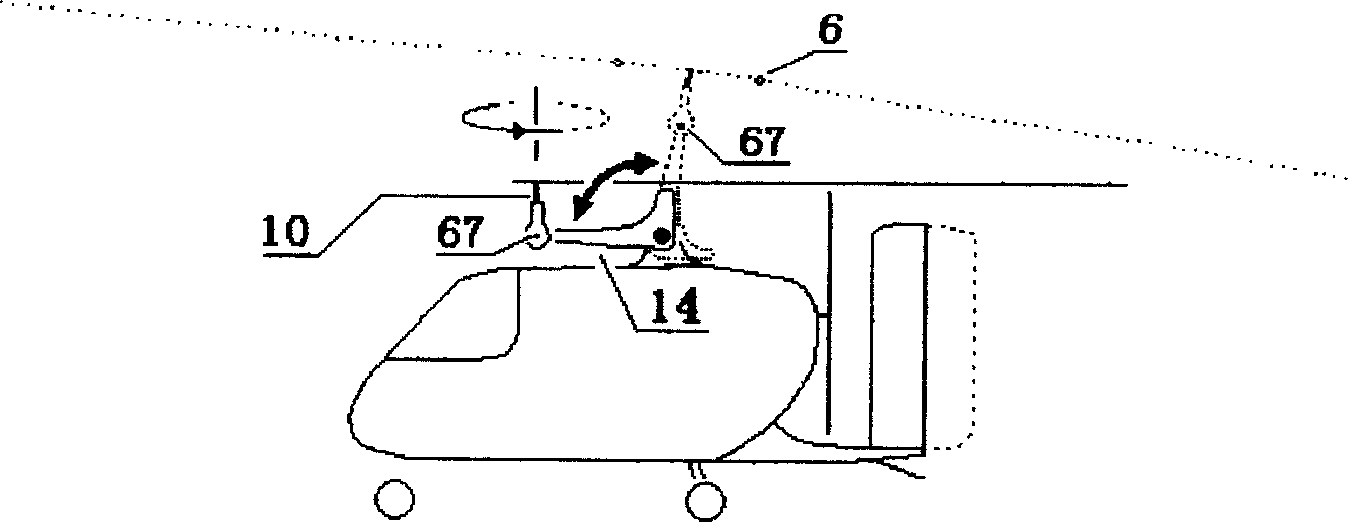

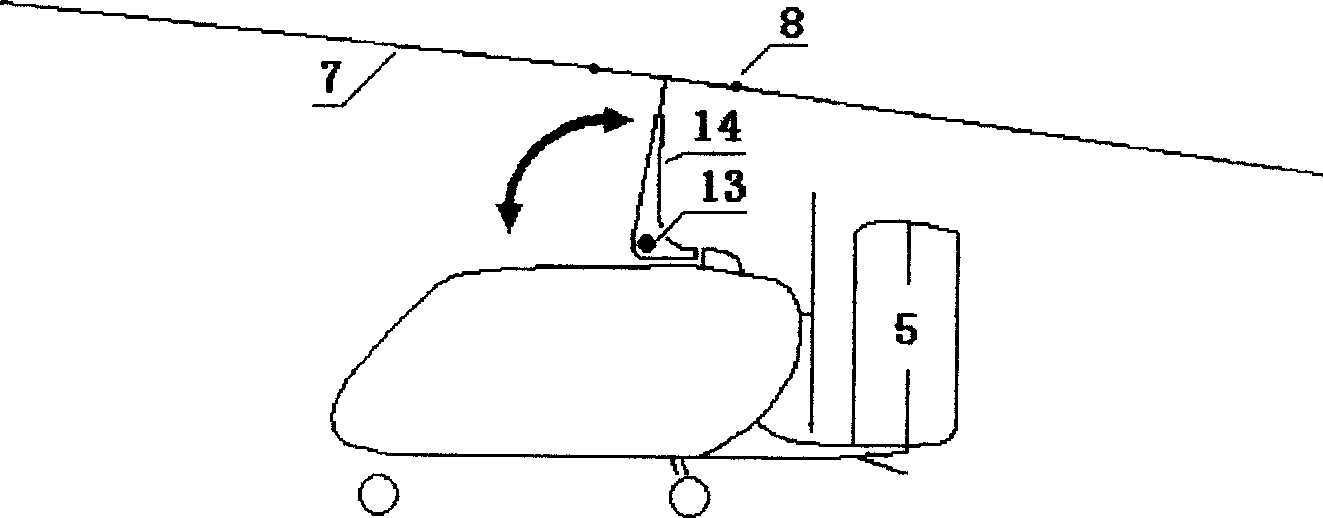

[0149] Figure 1 to Figure 8 , Figures 17, 18 and Figure 72 to Figure 7 Shown in 4, a kind of rotary wing flying car comprises parts such as fuselage, the power system of rotorcraft, horizontal propulsion drive propeller, empennage, landing gear, tilting storage type rotor strut 14 and folding rotor; Rotor strut 14 is erected and fixed Afterwards, the position of its installation, the backward inclination angle are identical with conventional rotorcraft, and the rotor that expands is autorotation rotor;

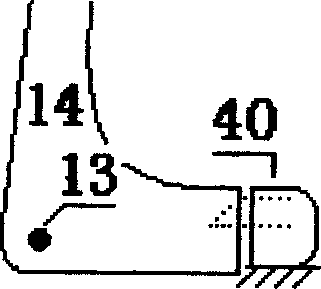

[0150] The lower end of the rotor prop 14 of the tilting storage type is connected with the top of the fuselage by the prop shaft 13, it can rotate to the longitudinal axis direction of the fuselage, tilt forward and store in a horizontal position; when its rotor prop 14 stands up, The prop positioning lock 40 that is fixedly installed on the fuselage can fix the rotor prop 14 and the fuselage together, and opening the prop positioning lock 40 can rotate the rotor prop 14 d...

Embodiment 2

[0153] Figure 125 As shown, the difference between this embodiment and "Embodiment One" is that the canopy 2 of this example can be opened forward, and the pilot can lean out from this, and the rotor at the upper end of the rotor strut 14 that is tilted forward is placed backward. Folding, other parts are the same as "Example 1".

Embodiment 3

[0155] The difference between this embodiment and "embodiment two" is that the canopy 2 of this example can be opened to the side, and the pilot can lean out from this, and the rotor at the upper end of the rotor strut 14 that is tilted and placed forward is folded backward, and other Part is the same as "Example 2".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com