Automatic blanking device

An automatic blanking and annealing tube technology, applied in glass fiber drawing devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of shortened service life of graphite parts, easy damage of IRIS and inserts, large errors, etc., to reduce down The effect of reducing material time, improving accuracy and working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

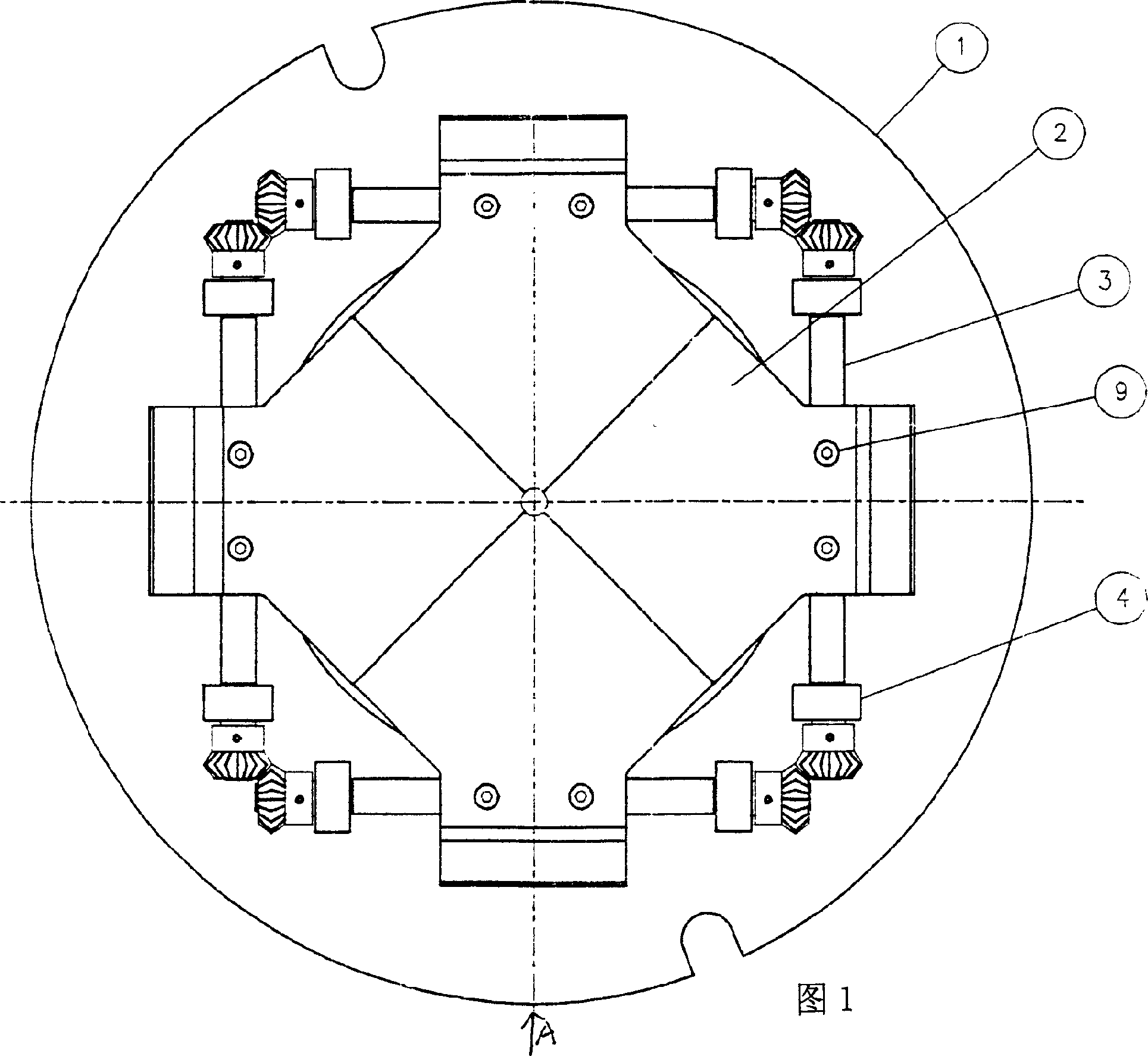

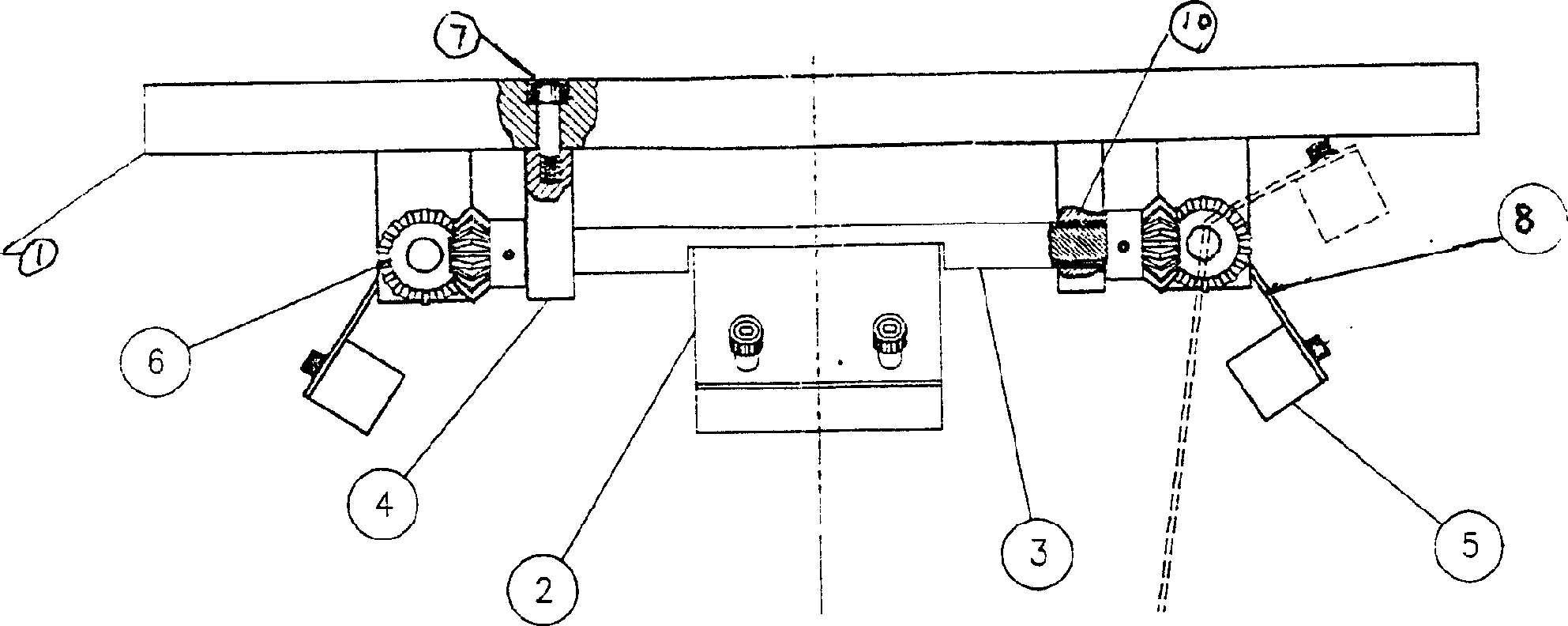

[0013] Figure 1, figure 2 As shown, the automatic unloading device connects four round rods 3 with copper gears 6 at both ends on the bottom plate 1 through the fixing parts 7, and the four round rods are mutually toothed to form a square frame. Four square iron sheets 2 are fixed, and the area of the four square iron sheets covers the inner diameter of the annealing tube; an iron rod 8 is correspondingly fixed at one end of each round bar, and a balance iron block 5 is fixed at the end of the iron rod. A pillow lock 4 is connected between the gear and the round bar. The pillow lock end of round bar is also provided with fine bearing 10.

[0014] Its working principle: When the light rod falls down, relying on its own gravity and the action of gears, it pushes away the four-corner iron sheet and falls from the annealing tube. When the pendant becomes a slender optical fiber, the force from top to bottom disappears, and the balance iron block produces a downward force due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com