Piston zero side pressure technology and apparatus of high efficient internal-combustion engine

An internal combustion engine, high thermal efficiency technology, applied in mechanical equipment, machines/engines, etc., can solve the problems of life force crisis and low thermal efficiency, and achieve the effect of improving thermal efficiency and eliminating piston side pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

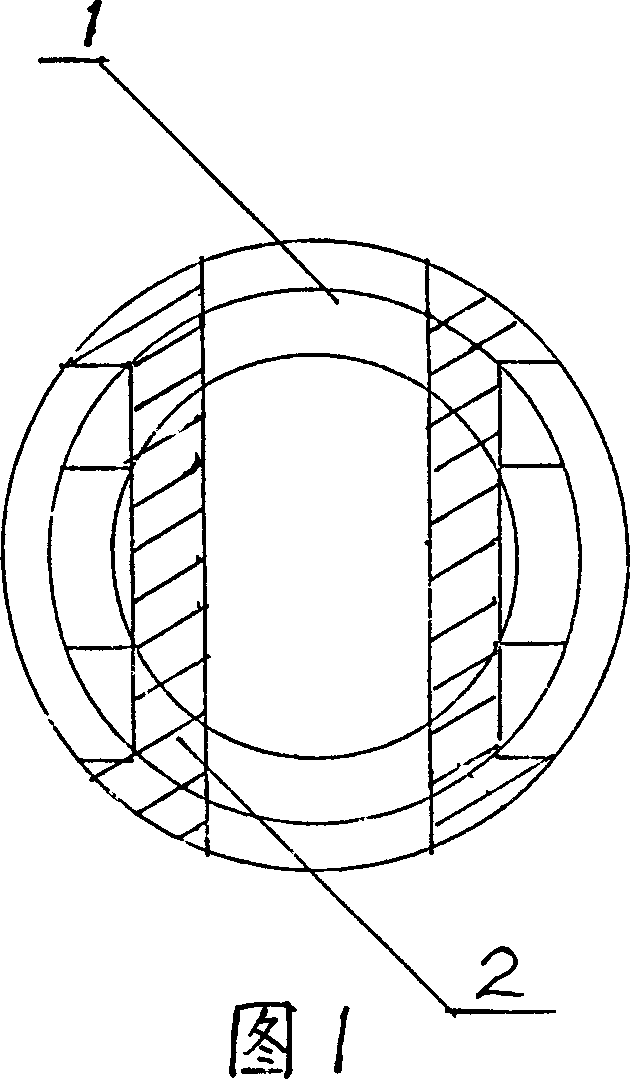

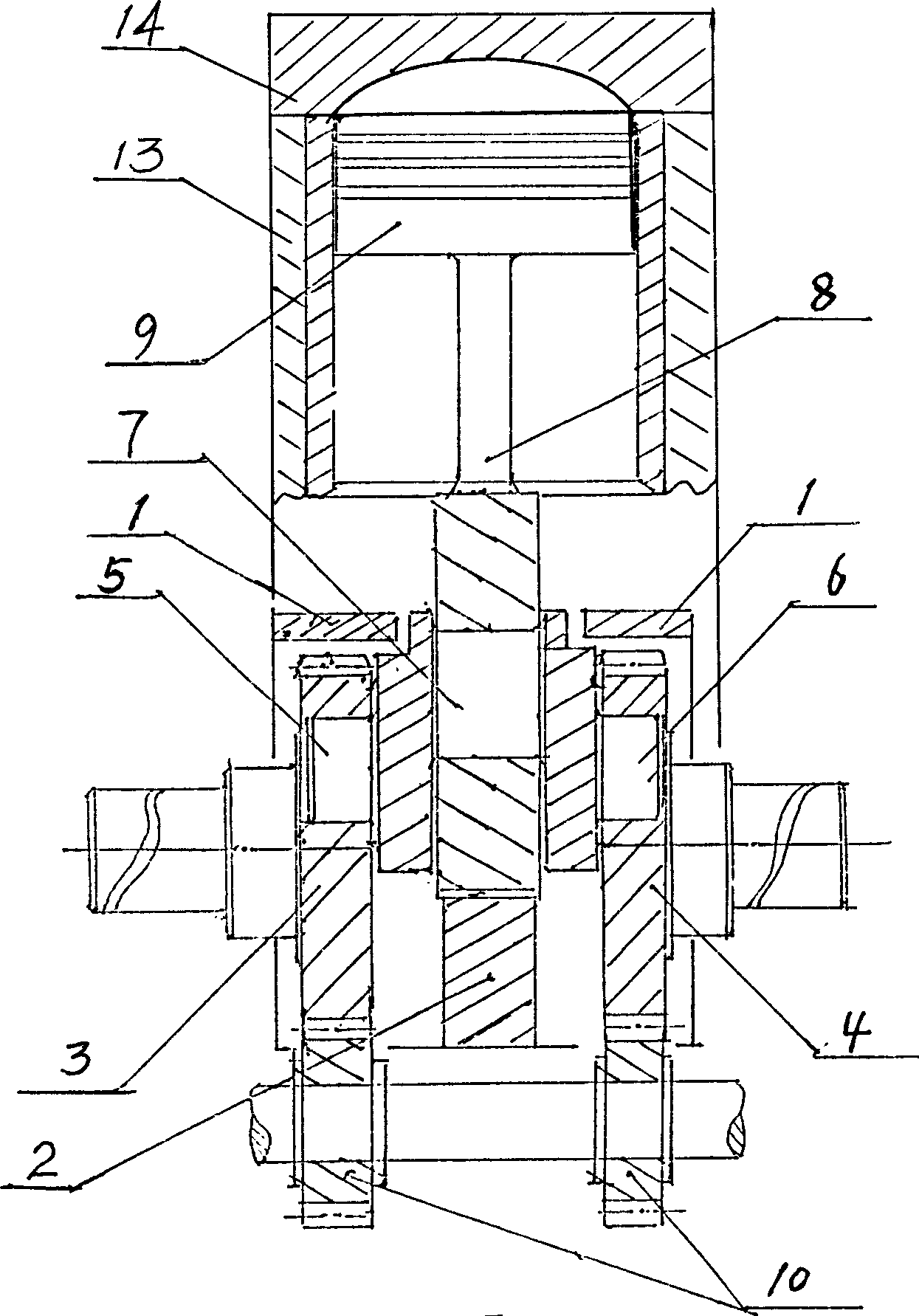

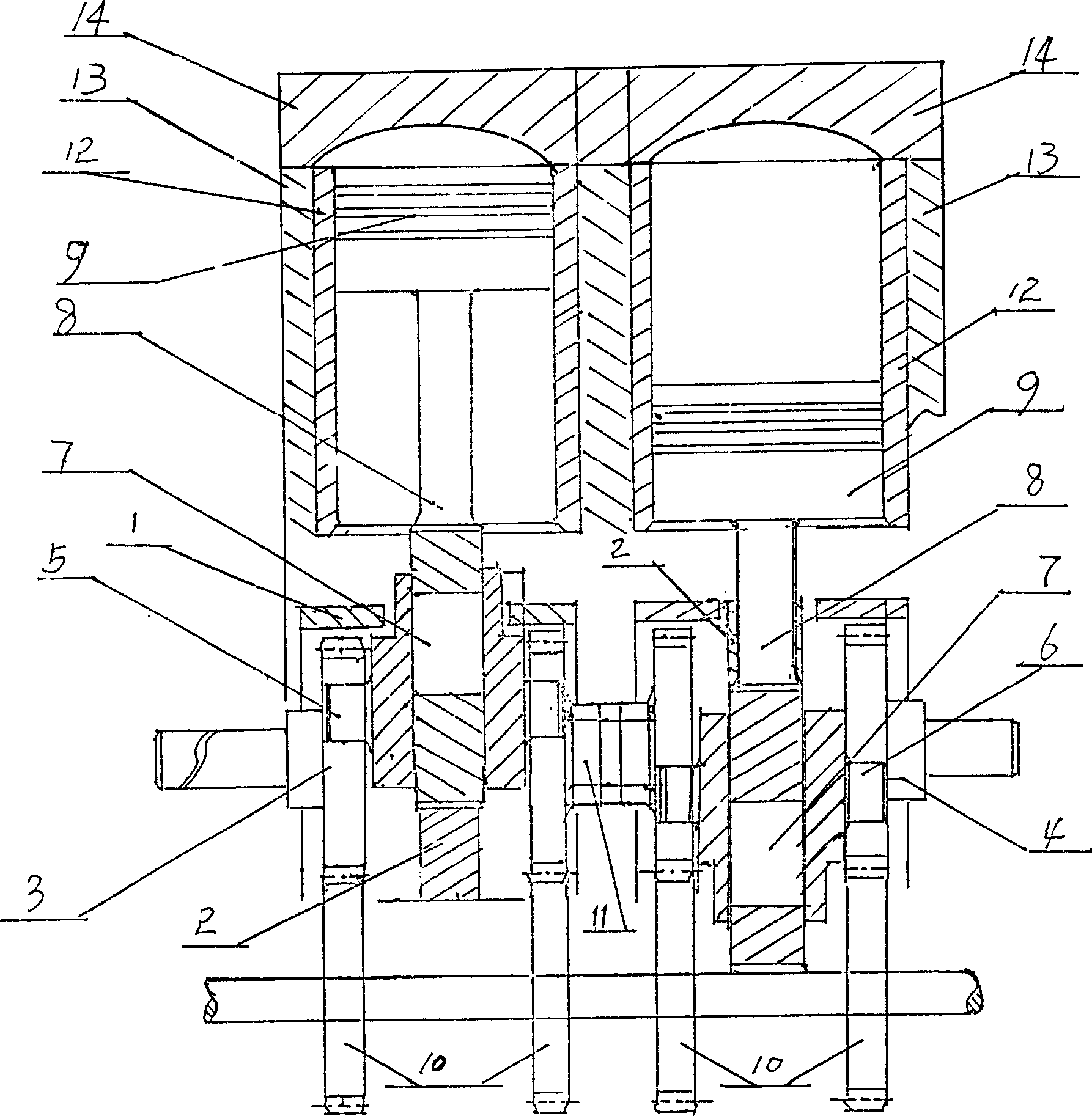

[0022] A, to the embodiment of single-cylinder internal combustion engine:

[0023] ① For example, if the internal combustion engine is modified with a crankshaft, first cancel the crankshaft of the original engine, and then install the sliding seat 1 with double guide rails 2 under the foot of the cylinder and fix it. Crankshaft 7 is connected, and slide block installation is seated in double guide rail 2 the insides and can reciprocate slide again. And after the eccentric distance shaft holes 5 and 6 provided on the co-force chainring end of the left and right half shafts 3 and 4 are respectively aligned and connected with the two shaft ends of the small crankshaft, the original left and right half shafts can be easily rotated, installed and fixed on the original crankshaft on the bearing seat. The upper end of the push rod 8 is coupled with the piston 9 inside the cylinder 12 . According to the space conditions under the original crankshaft internal combustion engine cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com