Method for intensified mining deep-dished strip mine

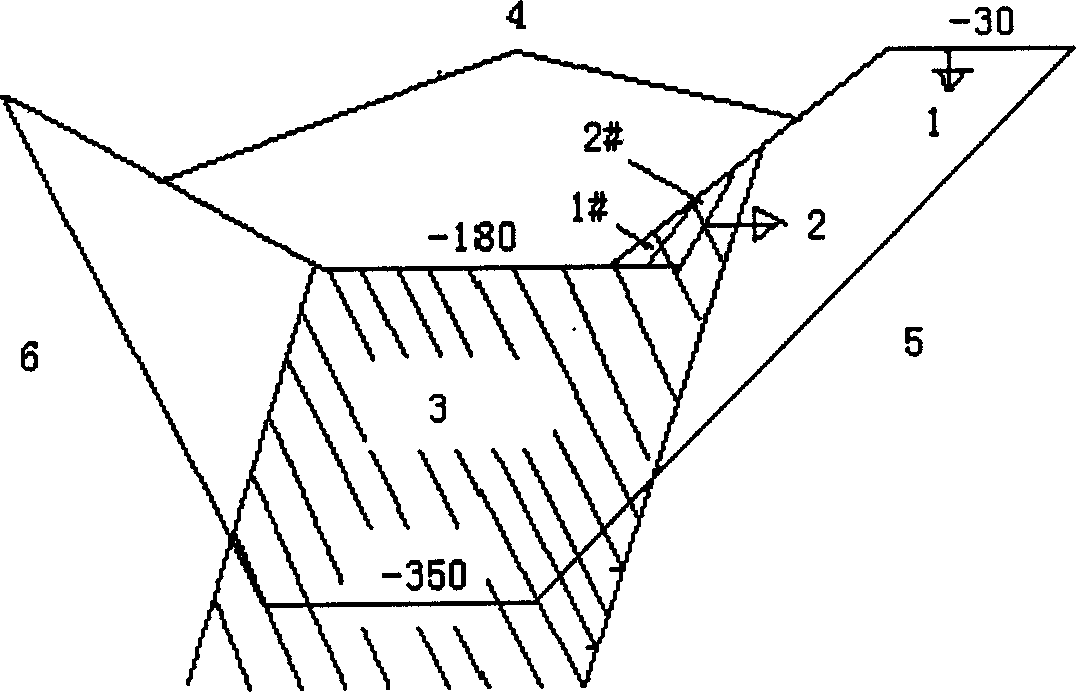

A technology of open-pit mine and section method, which is applied in surface mining, underground mining, special mining, etc. It can solve the problems of large amount of side expansion, slow decline of side expansion, and inability to solve the problem of stope depth extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

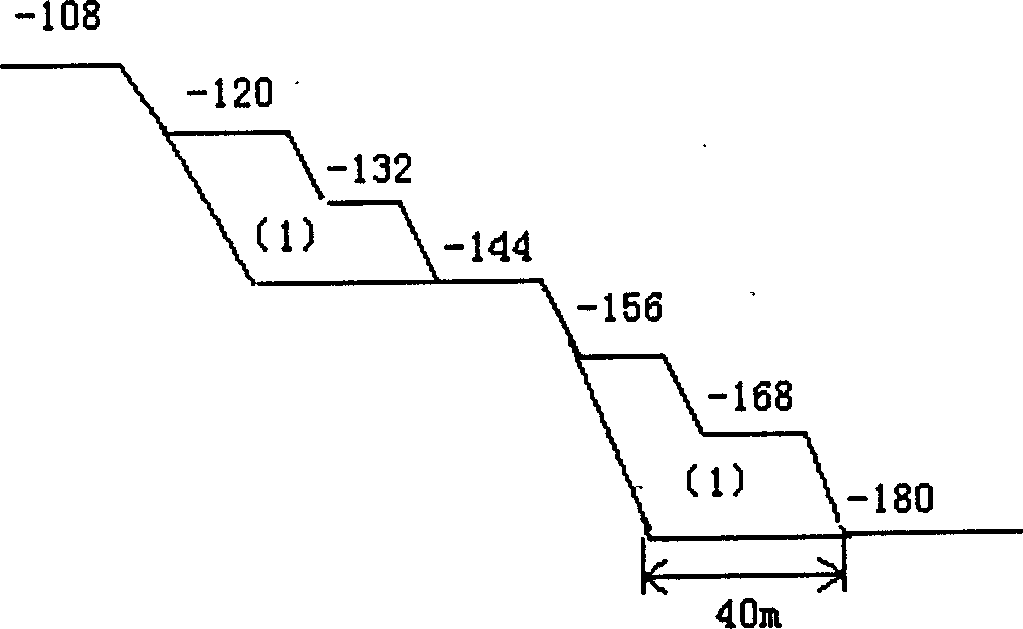

[0011] The first line has a width of 40 meters, with a total of 6 steps from -108m on the upper part to -180m on the lower part. In order to create more space for the bottom of the stope, the three steps of -120m, -132m, and -144m are combined into sections, and the three steps of -156m, -168m, and -180m are combined into sections. The slope angle of the steps after the section is 55 degrees, a 25m wide platform is left at the -144m level to prepare for the next strip mining.

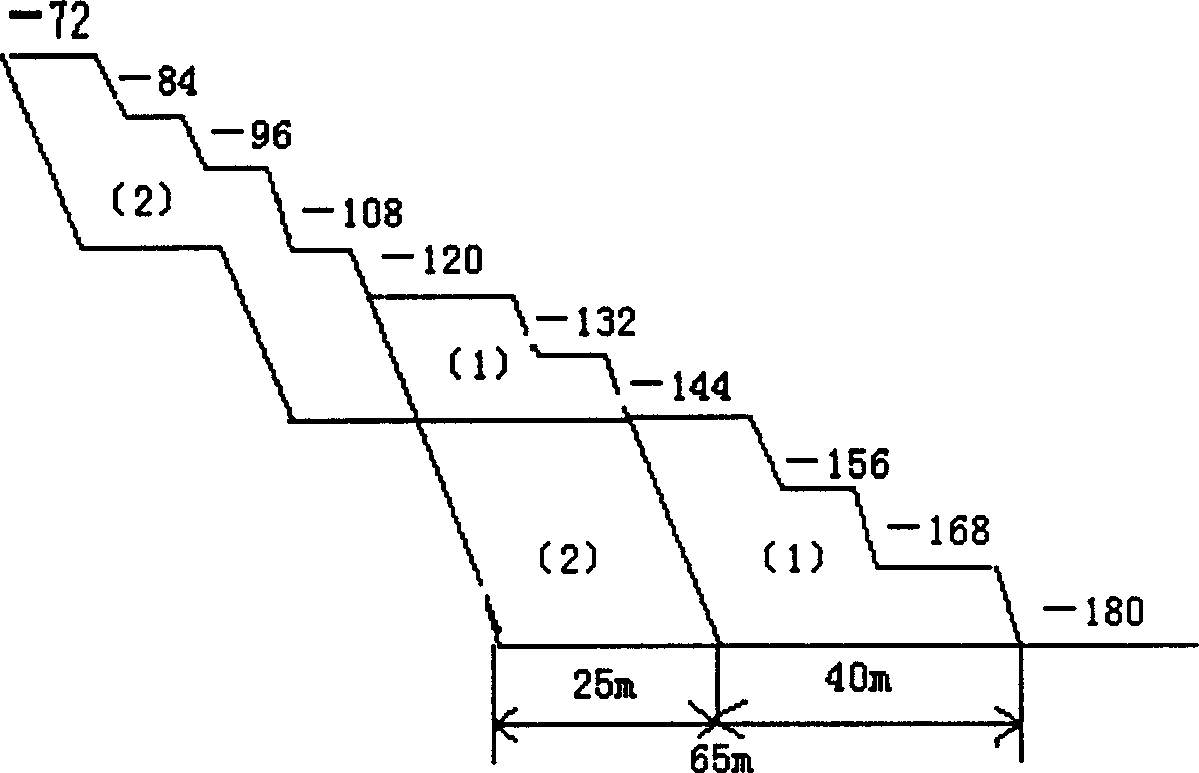

[0012] The second strip has a width of 25 meters, and the upper step is from -72m to the lower part -180m, a total of 9 steps. In order to create more space for the bottom of the stope, three steps of -84m, -96m and -108m are combined, three steps of -120m, -132m and -144m are combined, and three steps of -156m, -168m and -180m are combined. The steps are merged, and the slope angle of the steps is 55 degrees after the merger. A 25m wide platform is left at the -144m level to prepare for the next strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com