Drive circuit for plasma display screen

A technology for driving circuits and plasmas, which can be used in static indicators, instruments, identification devices, etc., and can solve problems such as excessive power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

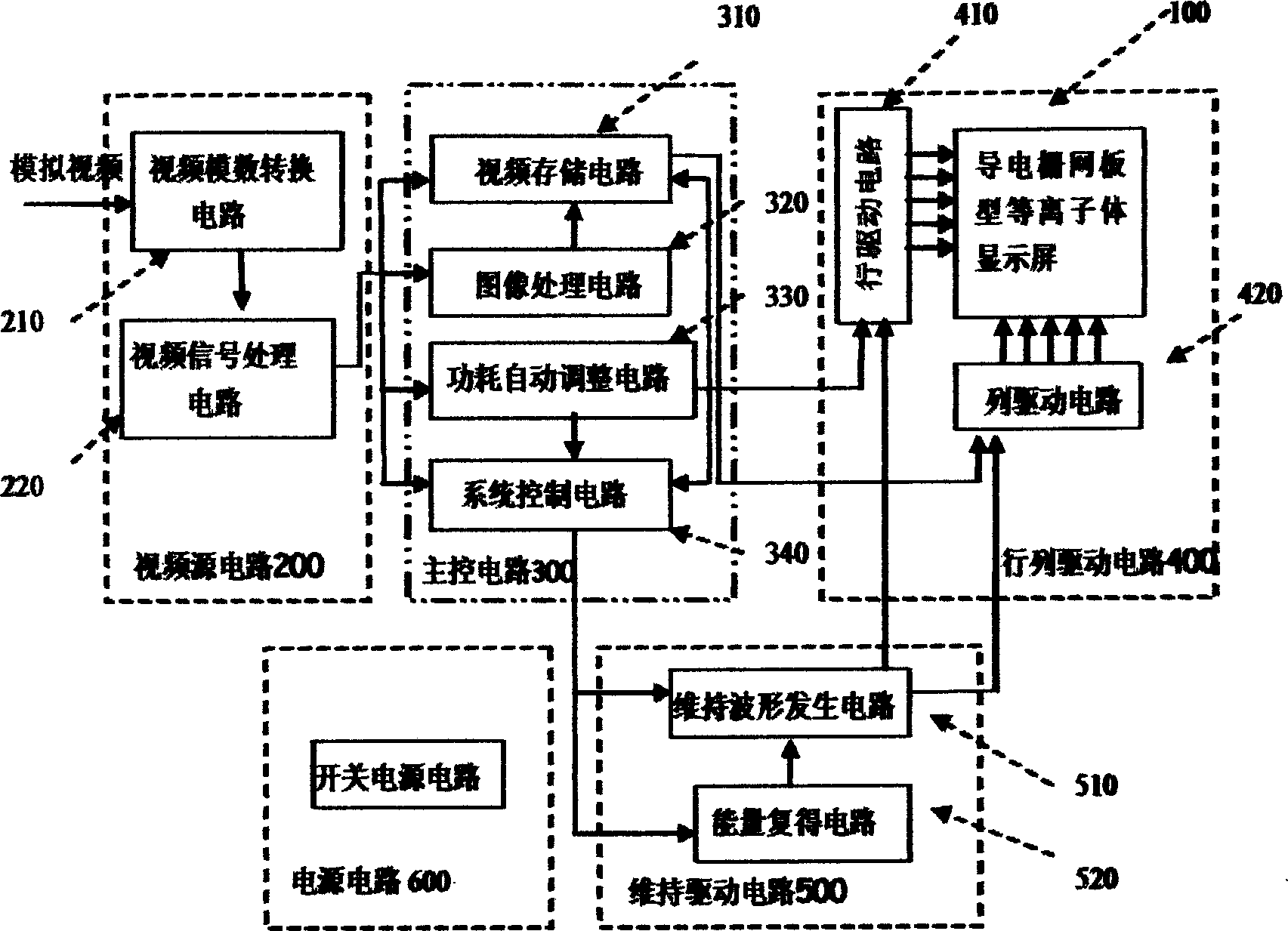

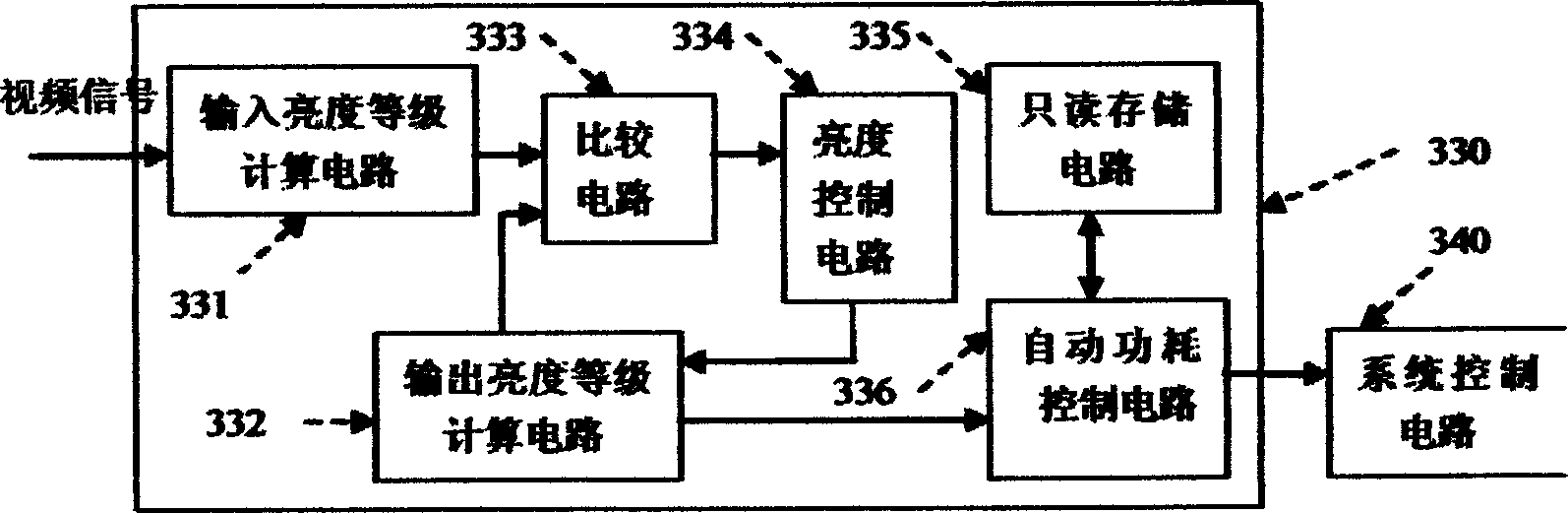

[0041] On the basis of the above-mentioned invention, further consider specific implementation schemes, and propose the following examples. In the video source 200 of this driving circuit, the input terminal of video analog-to-digital conversion circuit 210 is connected with analog video signal, and the output terminal is connected with video signal processing circuit 220; The input terminal of image processing circuit 320 in the main control circuit 300 is connected with video signal The output terminal of the processing circuit 220, the output terminal of the image processing circuit 320 is connected to the video storage circuit 310, the output terminal of the video storage circuit 310 is connected to the column drive circuit 420, and the output terminal of the power consumption automatic adjustment circuit 330 is connected to the system control circuit 340 and the system control circuit 340 respectively. The input end of the row driving circuit 410, the input end of the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com