Method for realizing short gauge jumping rail through employing step motor

A stepping motor and short track technology, which is applied in the field of controlling the stepping motor, can solve the problems of sacrificing the performance of the optical disc drive, low optical signal quality, slowing down, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

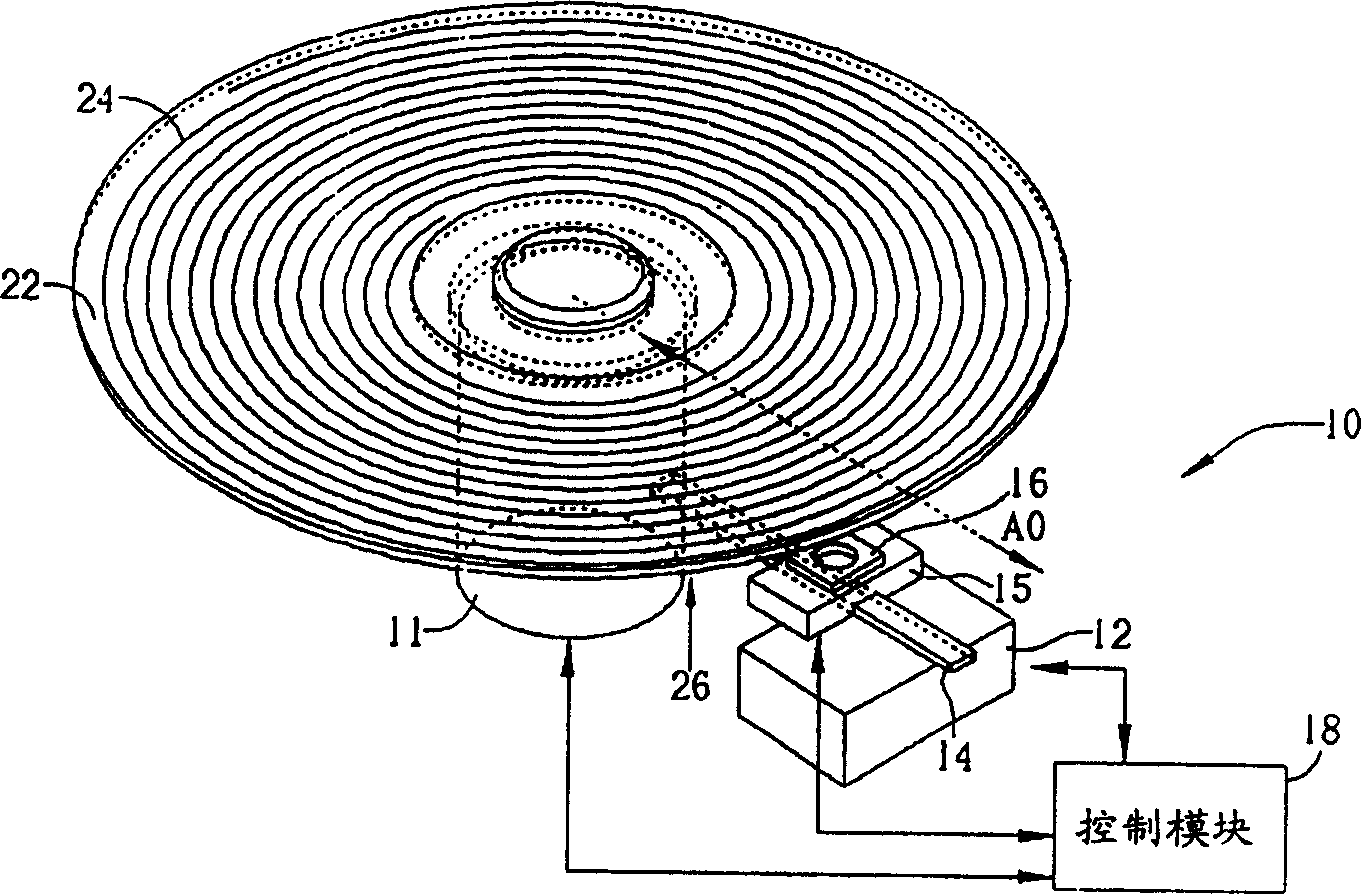

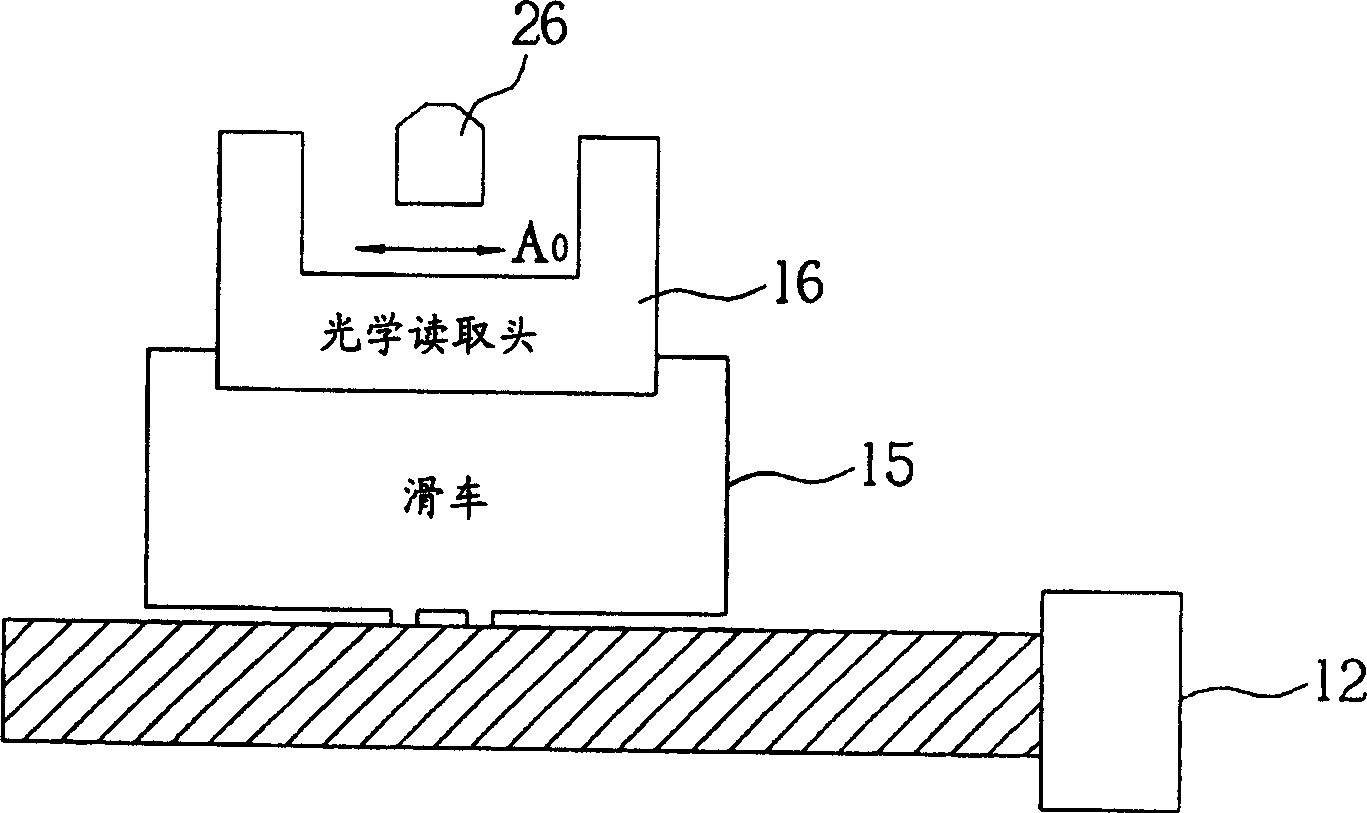

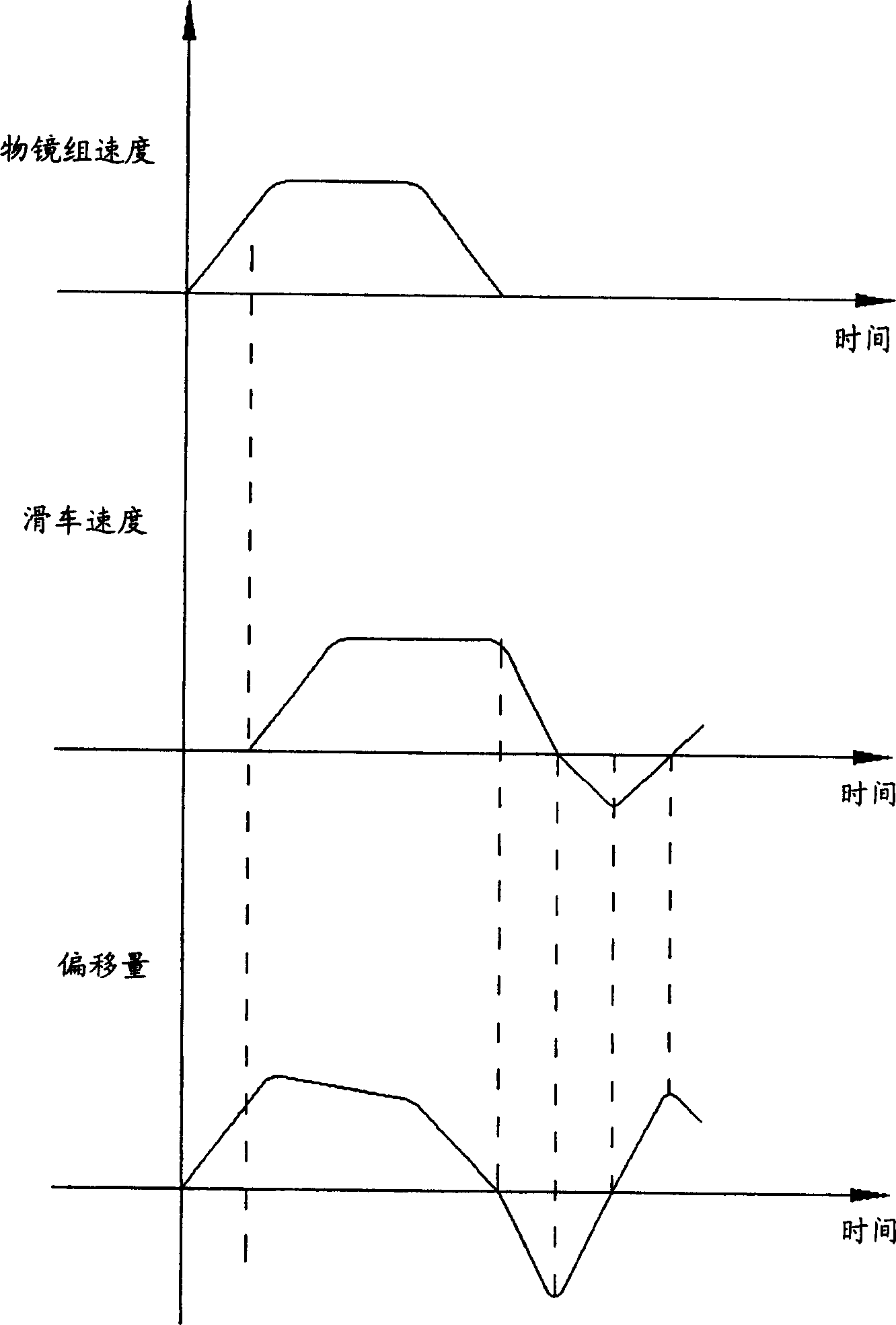

[0026] Firstly, the technical feature of the present invention is based on the use of a stepping motor, and uses the stepping motor to drive a pulley and an optical reading head to achieve the effect of pre-driving and precise positioning. Stepping motors are widely used in industry, and have been gradually popularized in the application of microcomputer peripheral equipment. Generally speaking, a stepping motor operates in a stepping manner. As long as a square wave signal is input, the stepping motor can determine the angle of rotation according to the amount of the square wave signal. When there is no square wave signal, the stepping motor maintains a static state, and when a continuous square wave is given, the stepping motor rotates continuously at a fixed angle. In this way, the stepping motor can perform instant start and rapid stop, and can achieve precise position control. Generally, the stepping motor 32 rotates a relatively large distance, so the general optical di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com