Reinforcement and cooling structure of a turbine blade

A technology of turbine blades and blades, which is applied in the direction of blade support components, stators, engine components, etc., can solve the problems of reduced overall efficiency and cooling efficiency, and achieve high overall efficiency, high cooling efficiency, and good heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

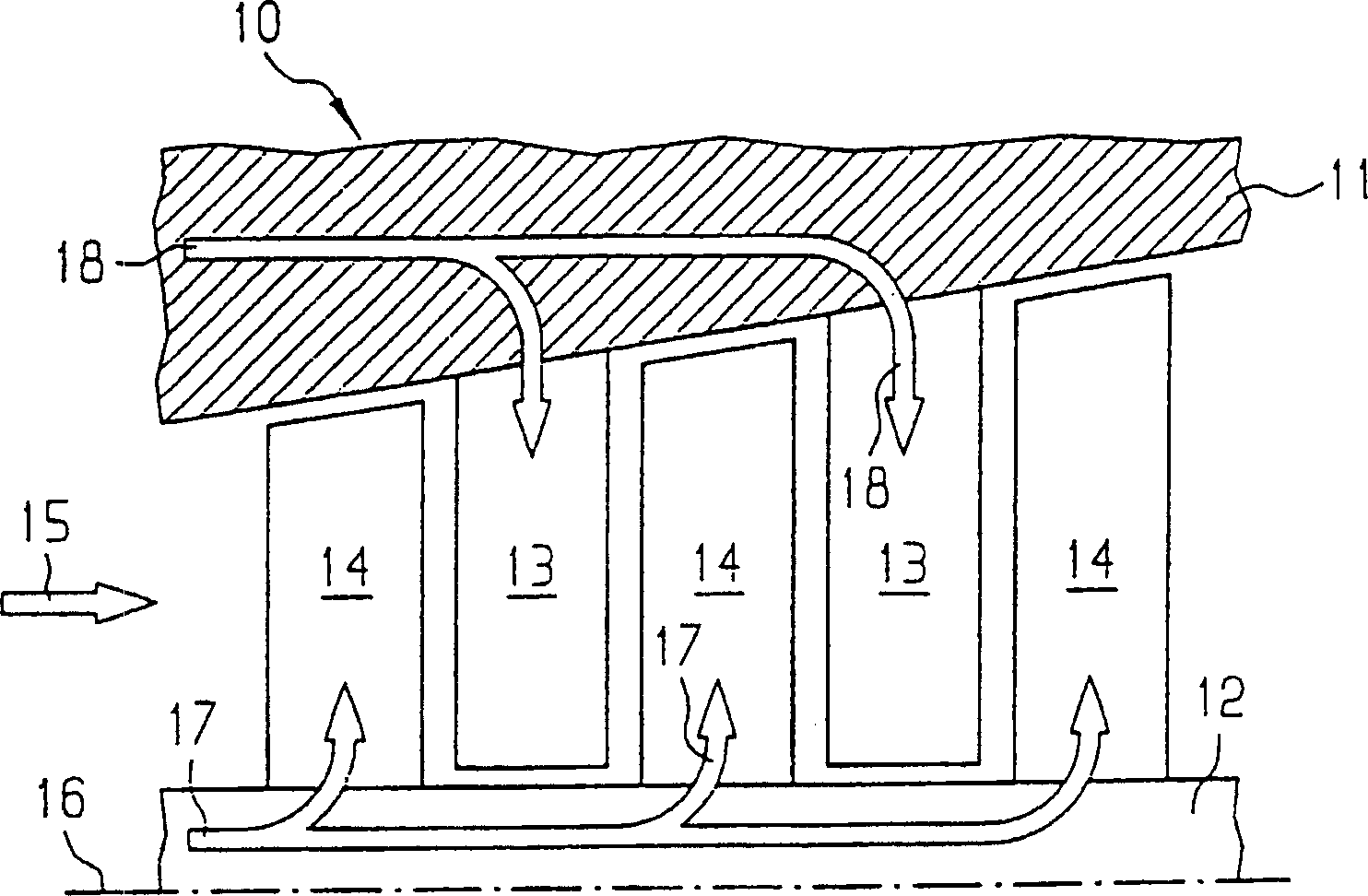

[0028] figure 1 A longitudinal sectional view of a turbine shown as a turbine 10 with a casing 11 and a rotor 12 . The housing 11 is provided with guide vanes 13 and the rotor 12 is provided with rotor blades 14 . In operation, fluid flows through turbine 10 in direction of arrow 15 , the fluid flows along guide vanes 13 and rotor blades 14 , causing rotor 12 to begin rotating about centerline 16 .

[0029] In most applications, the temperature of the fluid is high, especially in the region of the first row of blades ( figure 1 shown in the center left). For this purpose, the guide blades 13 and the rotor blades 14 are cooled. The flow of cooling fluid is schematically indicated by arrows 17 , 18 . In particular air can be used as cooling fluid.

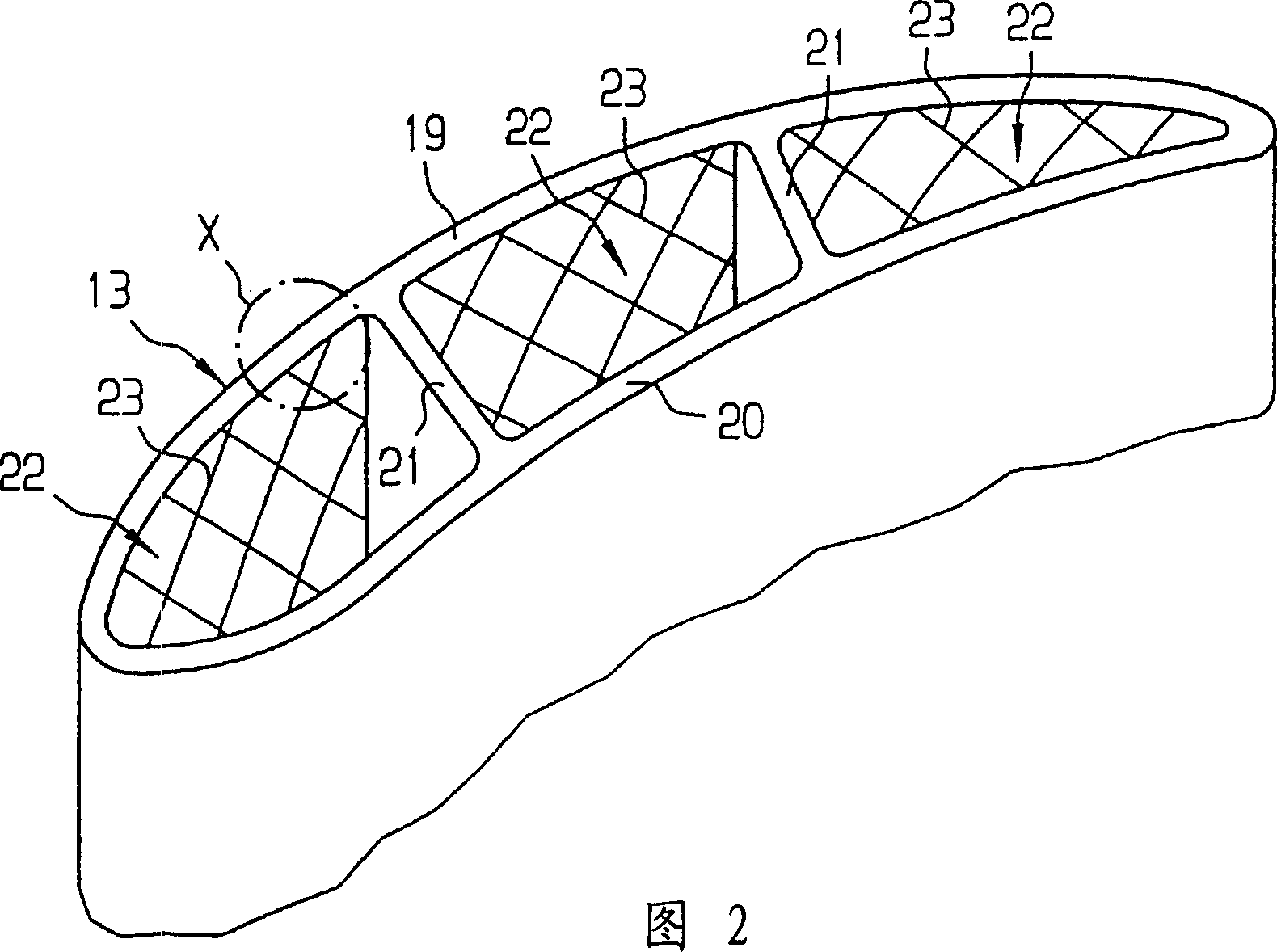

[0030] FIG. 2 schematically shows an exploded view of the guide vane 13 . The guide vanes 13 have curved outer walls 19 , 20 . The interior space between the outer walls 19 , 20 is subdivided by means of two partition walls 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com