Superfine continuous machining process for silicon iron powder

A processing technology and technology of ferrosilicon powder, which is applied in the field of ultrafine and ultrafine continuous processing technology of ferrosilicon powder, can solve the problems of long crushing time, low production efficiency, and difficult quality assurance, so as to prevent material oxidation, high production efficiency, The effect of stable material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

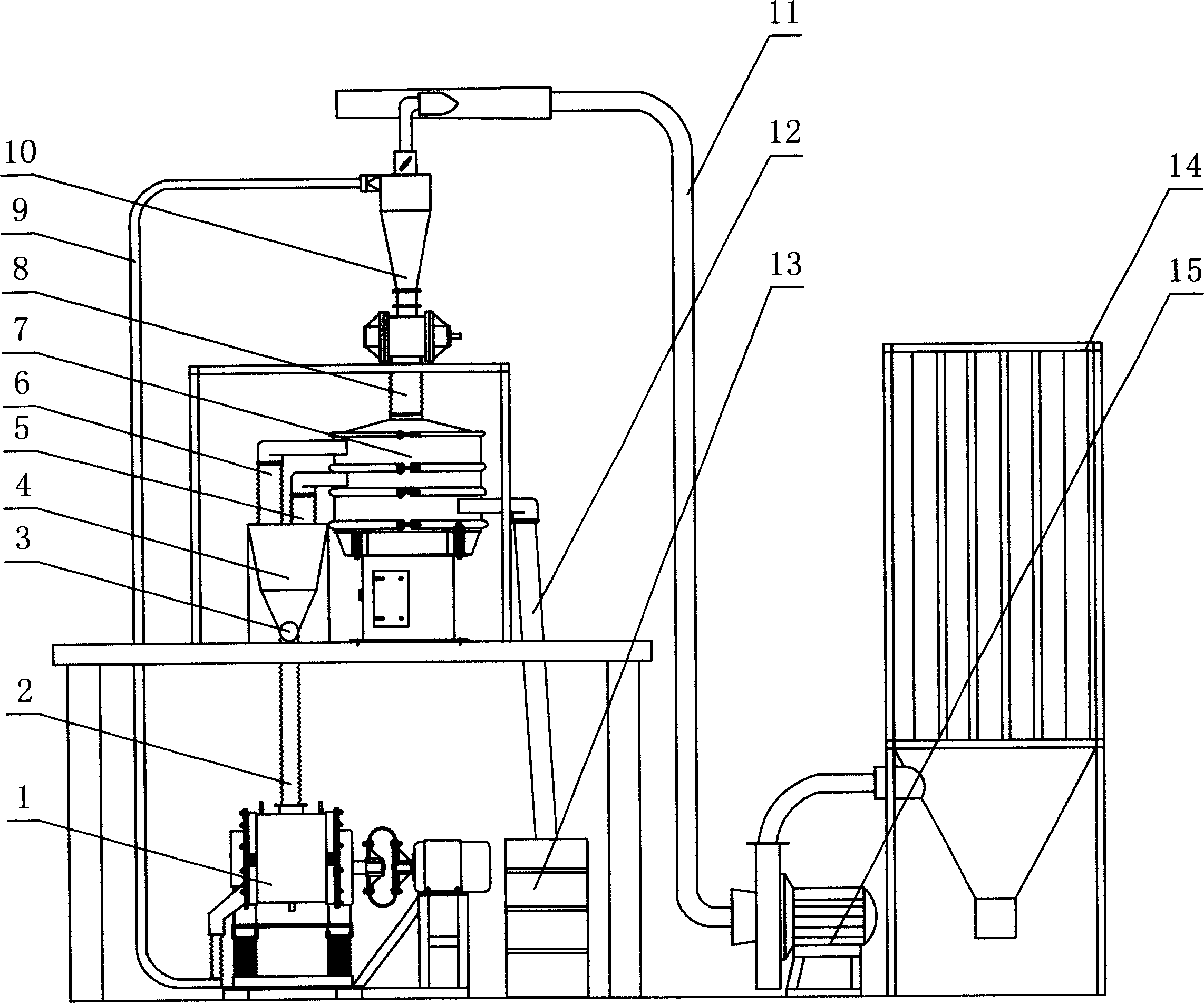

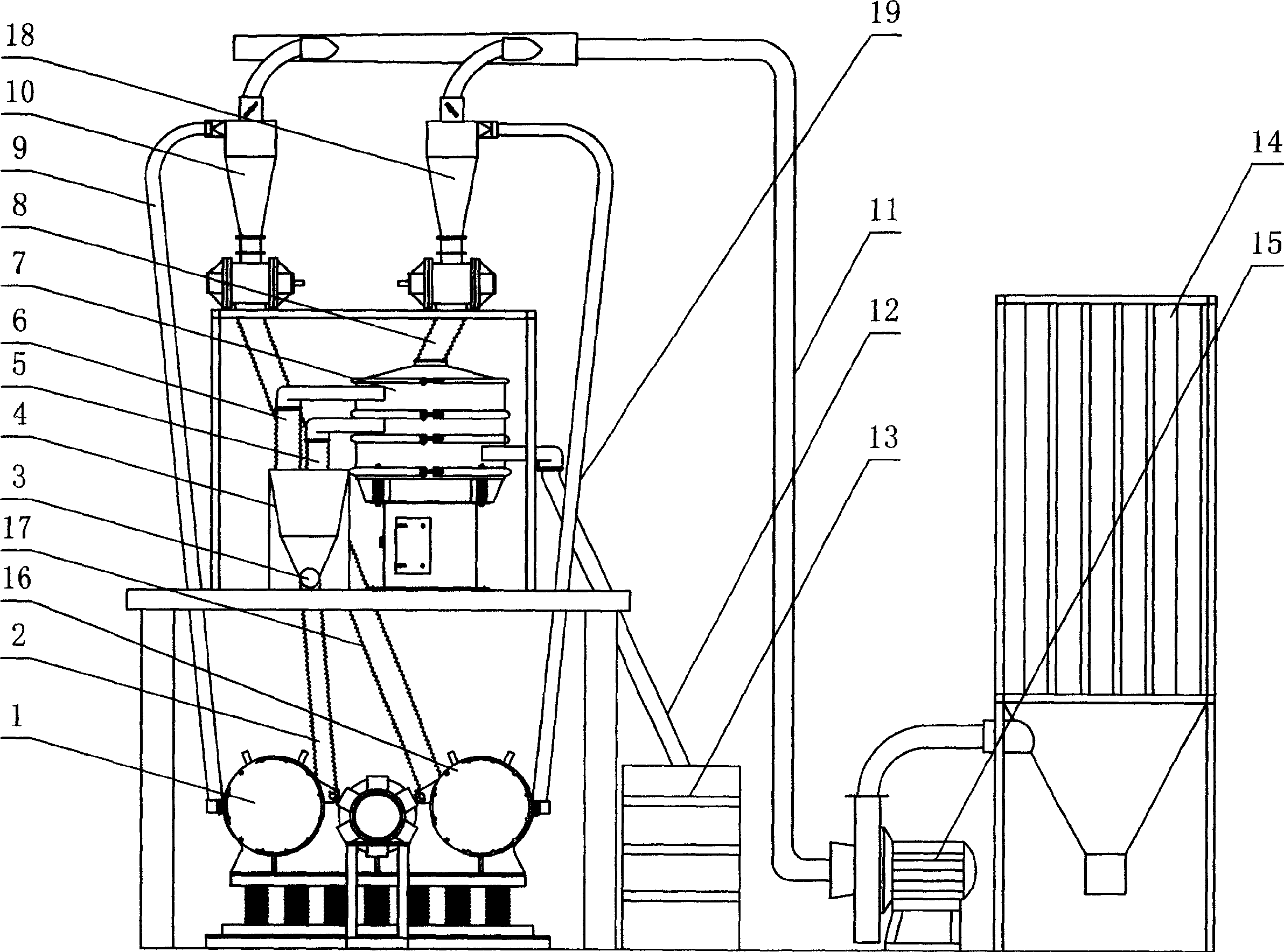

[0013] The production equipment used in this process is as follows: figure 1 Alternate installation shown.

[0014] After the production equipment is ready, when the processing and production of ferrosilicon powder needs to be carried out, the centrifugal fan 15 is started, and the centrifugal fan 15 makes the cyclone unloader 10 enter the working state through the air duct 11, and then the granular ferrosilicon powder after pre-crushing Put it into the hopper 4, and send it to the high-frequency vibration mill 1 through the material pipe 2 through the screw feeder 3 for ultra-fine crushing, and the ultra-fine crushed ferrosilicon powder passes through the material pipe 9 under the action of the cyclone unloader and feed pipe 8 into the multi-stage screening machine 7 for screening, the qualified part of the ferrosilicon powder is screened and classified and transported into the stocker 13 through the feed pipe 12, and the unqualified part passes through the feed pipe 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com