Anti-oxidation device and method for calcining and preparing new material

A new material, anti-oxidation technology, applied in chemical instruments and methods, chemical/physical processes, heat treatment, etc., can solve problems such as expensive equipment cost and maintenance, low precision requirements, and complicated operation of vacuum heat treatment furnaces. Inexpensive, easy to operate, and the effect of preventing material oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with specific embodiments.

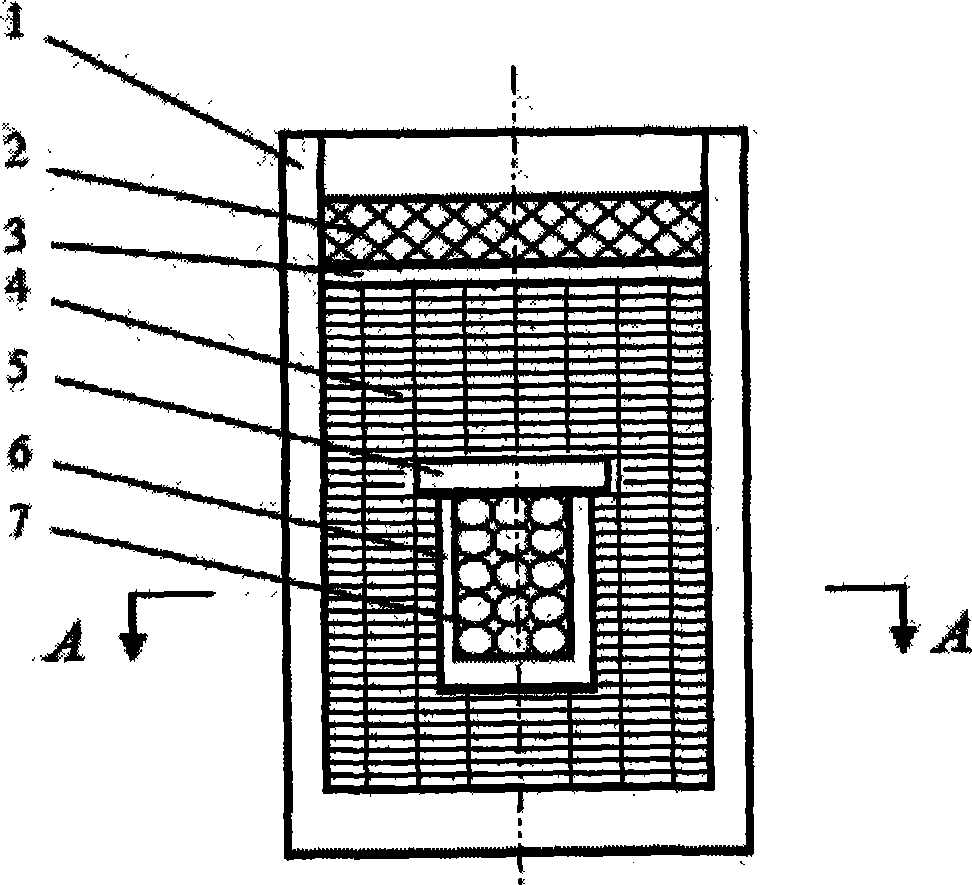

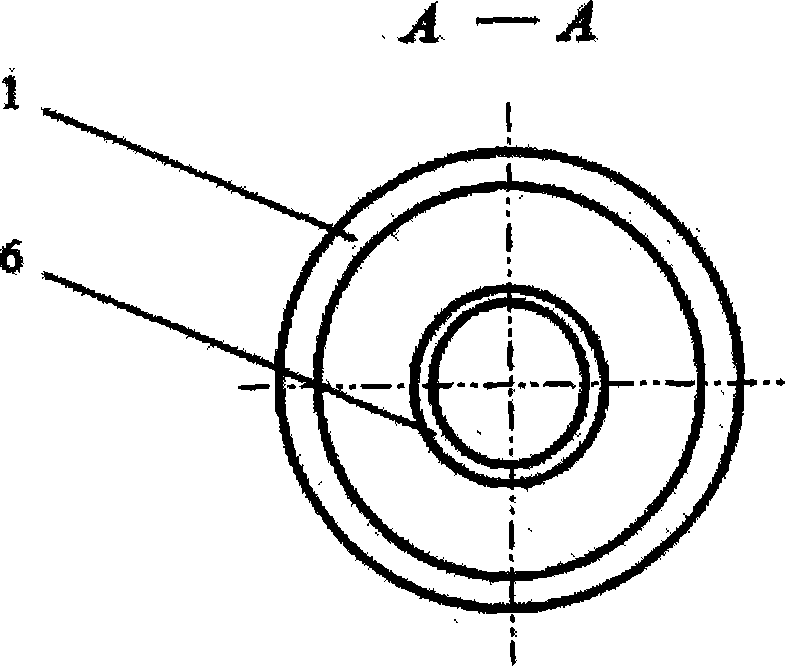

[0018] The present invention is realized through the effective combination of internal and external systems, such as figure 1 , figure 2 As shown, the internal system includes a small crucible 6 with a small crucible cover 5, and the material 7 to be calcined is contained in the small crucible 6. The external system includes a large crucible 1, and the small crucible 6 is placed inside the large crucible 1. The bottom of the large crucible 1 Filled with high-temperature oxygen-loving powder 4 (such as charcoal powder, graphite powder, etc.) that can completely embed the small crucible 6, the top of the large crucible 1 is filled with a sealing layer 2 (such as refractory soil, water glass sand, etc.) ), between the refractory soil layer 2 and the high-temperature oxygen-loving powder 4, there is a waterproof isolation material 3 (such as a plastic film, a thick paper sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com